Scope

The ADF Wear Debris Analysis Laboratory (ADF WDA Lab) provides specialised analysis of metallic particles to enable rapid and accurate assessment of aircraft propulsion system serviceability.

The metallic particles are generally recovered from magnetic chip detectors/collectors, screens or filters fitted to aircraft propulsion system components (e.g. engines or gearboxes) or hydraulic systems. The laboratory also provides support for associated condition monitoring programs by providing detailed analysis of wear debris particles.

General Information

Analysis typically involves a combination of the following:

- Elemental composition

- Size

- Quantity

- Morphology (e.g. features, colour etc.).

The significance and potential origin (e.g. gear or bearing) of the particles can then be determined and used to make an informed maintenance or serviceability decision. The laboratory has access to a range of platform metal maps (lists of components and their alloys) to support the analysis.

There are 3 turn-around priorities available to lab users (from receipt of samples):

- 48 hours – requires short justification (e.g. aircraft required for deployment)

- 7 days

- 14 days.

The minimum information required for each sample is:

- Aircraft tail number

- Component serial number

- Date the sample was captured.

All requests for analysis must be made via the AE639 Web Form.

All samples are retained for a minimum of 12 months before disposal. Samples and data used by this lab can be made available to third parties (e.g. OEMs) on request from the relevant CAMO.

The ADF WDA Lab is a free service for all ADF units. Contractors and other Non-ADF organisations should contact their relevant CAMO prior to requesting WDA services.

Any queries about specific reports are to be made to the ADF WDA Laboratory Technical Manager (Dr Andrew Becker) or the DASA PSI1 incumbent (see contact details below).

Instructions

Taking a Sample:

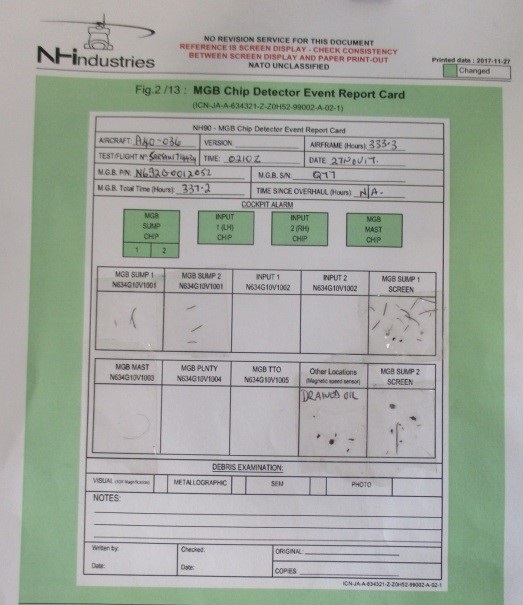

(i) Chip Detectors: Typically chip detectors/collectors are rinsed using Isopropyl Alcohol (IPA) after removal from the aircraft to remove residual oil. Once dry, the debris is carefully transferred to a paper form using Scotch Magic Tape 810D (or similar). The paper form should clearly identify the location within the component that the debris was collected from (e.g. MGB Mast, Engine Accessory Gearbox etc.), see below example.

Wear debris

Example form (ii) Filters: Allow surplus oil to drain from the filter element (this can also be captured in a sample bottle but is not essential). Double bag the sample in zip lock or similar bags. Place bagged filter in a box with absorbent material.

- Submit the completed electronic AE639 Web Form using embedded button at the end of the form (emails the form to ADF.WDA@defence.gov.au).

Sample delivery options are:

(i) Via Australia Post to:

ADF Wear Debris Analysis Lab

PO Box 322

Port Melbourne, VIC 3207

(ii) Via Courier

ADF Wear Debris Analysis Lab

Defence Science & Technology Group

c/- Main Store Building 114

506 Lorimer Street

Fishermans Bend, VIC 3207

- The WDA results will be emailed to the POC and any nominated recipients listed on the AE639 form.

Note: Routine oil samples must not be sent to the ADF WDA Lab. Routine oil samples are analysed by a commercial laboratory (Intertek) under a contract managed by Fuel Services Branch (see POC details below). The ADF WDA Lab can analyse particulate from oil samples in exceptional circumstances (contact the lab before sending).

POCs

All questions can be directed to the WDA Lab Technical Manager, Dr. Andrew Becker in the first instance.

Email: adf.wda@defence.gov.au

Lab Mobile: 0456 899 233

Emergency alternate email: dasadaveng.submission@defence.gov.au

For queries regarding oil analysis, please refer to the following:

Email: adf.polq@defence.gov.au