DASR 21 - Aircraft Design, Production and Certification

21.1 - General

GMGM

GM 21.1 - General (AUS)

As the sponsor of DASR 21, unless otherwise stated the Authority will mean 'DASA'.

DASR 21 is only applicable to aircraft on the Defence register; non-Defence (civil) registered aircraft will continue to abide by the regulations of the applicable civil aviation authority.

When reference is given to ‘design organisation’ the following shall apply:

An organisation responsible for the design of products, parts and appliances or for changes or repairs thereto shall demonstrate its capability in compliance with national military airworthiness regulation being in accordance to this DASR, further referred to as DASR 21. In the case that governmental organisations undertake design activities with any other organisation responsible for the design of products, parts and appliances or for changes or repairs thereto, they shall be treated as a single organisation when demonstrating their capability in accordance with DASR 21.

By way of exception from point 1, an organisation whose principal place of business is in a non-participating Member State, or where a participating Member State (pMS) has not yet transposed EMAR 21 in their national military airworthiness regulations, may demonstrate its capability by holding a certificate or similar approval issued by an authority of that State for the product, part and appliance for which it applies, provided:

that State is providing oversight as State of Design; and

through Recognition (EMAD–R) it can be determined, that the national airworthiness system of that State includes the same independent level of checking of compliance as provided by DASR 21, either through an equivalent system of approvals of organisations or through direct involvement of the authority of that State.

All references to 'aircraft' throughout this DASR means 'military aircraft', defined as those that follow special laws and regulations and are designed with specific characteristics for military operations.

‘Authority’ shall be, unless otherwise specified in this DASR:

The Authority in charge of the type certification process:

For a multinational programme, the Military Airworthiness Authorities of the participating Nations/States; or

For a national programme, the Military Aviation Authority of this Nation/State,

The Authority in charge of the production / design organisation approval:

For a multinational programme, the Military Airworthiness Authorities of the participating Nations/States; or

For a national programme, the Military Aviation Authority of this Nation/State,

The Authority in charge to issue the military permit to fly

The registration Authority in charge to issue the Certificate of Airworthiness; or

For unregistered aircraft, the Authority which prescribed the identification marks.

‘Applicant’ shall be:

The contractor which should comply with this DASR; or

Any organisation which must obtain from an Authority a type-certificate, a restricted type-certificate, a supplemental type-certificate, an Australian Military Technical Standard Order (AUSMTSO) authorisation, a major change or a major repair design approval based on this DASR. It should be included herein the certificate of airworthiness, as mentioned in DASR 21.A.172, and Military Permit to Fly / Flight Conditions, as mentioned in DASR 21.A.703.

Any organisation or operator or its representative which applies for an airworthiness certificate under Subpart H of this DASR.

‘Certification’ - the process of recognition that a product, part or appliance, organisation or person complies with the applicable airworthiness requirements followed by the declaration of compliance.

'continued (design) airworthiness' means all tasks to be carried out to verify that the conditions under which a type-certificate or a supplemental type-certificate has been granted continue to be fulfilled at any time during its period of validity (Type Design)

'continuing (preservation of) airworthiness' means all of the processes ensuring that, at any time in its operating life, the aircraft complies with the airworthiness requirements in force and is in a condition for safe operation (Maintenance).

All references to 'certificates' throughout this DASR means 'military certificates (Although credit can be taken from any prior Civil Certificate issued by a recognised Civil Authority).

All references to 'organisation approvals' throughout this DASR means 'organisational approvals accepted or issued by military authorities'.

Where this DASR requires specific DASR forms to be used, equivalent forms approved by the Authority are permitted.

“Operational Suitability Data (OSD)” means data, which are part of an aircraft type-certificate, restricted type-certificate or supplemental type-certificate, which may consist of the following:

the minimum syllabus of pilot type rating training, including determination of type rating;

the definition of scope of the aircraft validation source data to support the objective qualification of simulators or the provisional data to support their interim qualification;

the minimum syllabus of maintenance certifying staff type rating training, including determination of type rating;

determination of type or variant for cabin crew and type specific data for cabin crew;

the master minimum equipment list.

SECTION A - TECHNICAL REQUIREMENTS

SUBPART A - GENERAL PROVISIONS

21.A.1 - Scope

This Section establishes general provisions governing the rights and obligations of the applicant for, and holder of, any certificate issued or to be issued in accordance with this Section. AMCAMC

AMC 21.A.1 - Scope (AUS)

Any design, Instruction for Continuing Airworthiness and other product approved under TAREG continues to be applicable and authoritative under DASR for its equivalent purpose, and hence does not require re-approval under DASR by default.

21.A.2 - Undertaking by another organisation than the applicant for, or holder of, a certificate

The actions and obligations required to be undertaken by the holder of, or applicant for, a certificate for a product, part or appliance under this Section may be undertaken on its behalf by any other person or organisation, provided the holder of, or applicant for, that certificate can show that it has made an agreement with the other person or organisation such as to ensure that the holder's obligations are and will be properly discharged. AMCAMC

AMC 21.A.2 - Undertaking by another organisation than the applicant for, or holder of, a certificate

In order to undertake the actions and obligations of the holder of, or applicant for, the certificate, the person or organisation should have an agreement in place with an approved Design Organisation who has access to the data related to the type design.

21.A.3A - Failures, malfunctions and defects

System for Collection, Investigation and Analysis of Data. AMCAMC AMC1AMC1 AMC2AMC2 AMC3AMC3 GMGM

GM 21.A.3A(a) - System for collection, investigation and analysis of data (AUS)

In the context of this requirement the word 'Collection' means the setting up of systems and procedures which will enable relevant malfunctions, failures and defects to be properly reported when they occur.

There are instances where a failure, malfunction or defect, or analysis of failures, malfunctions or defects represents some level of shortfall to the type design but may not result in a reportable occurrence in accordance with DASR 21.A.3A(b) based on an assessment of the available information at that time. In these situations, the holder ought to make a judgement as to whether the shortfall constitutes a risk or not.

Where the shortfall is judged to be within the level of safety inherent to the certification baseline, the holder should continue monitoring and assessing relevant information for risks to the type design.

Where a risk is judged to exist, the risk or hazard must be eliminated So Far As is Reasonably Practicable (SFARP), or if it is not practicable to do so, minimised SFARP in accordance with the requirements of the Work Health and Safety Act 2011, the Work Health and Safety Regulations 2011 and DASR SMS.A.25(b)(2.2).

In meeting the DASR SMS requirements the holder of the type-certificate, restricted type-certificate, supplemental type-certificate, AUSMTSO authorisation, major repair design approval or any other relevant approval deemed to have been issued under this DASR, should formalise arrangements with operators of the product to ensure timely and effective characterisation and communication of risks when deficiencies are being managed. This may constitute immediate communication in support of the development of a Service Bulletin, MPTF Flight Conditions, a Command Clearance, or other operator decisions affecting ongoing flying; or it may be periodic communication of shortfalls at the discretion of, or agreement with, the operator / down-stream duty holder.

AMC3 21.A.3A(a) - System for collection, investigation and analysis of data (AUS)

Foreign CAA/MAAs may issue Airworthiness Directives (ADs), or equivalent mandatory continuing airworthiness information. These are not automatically applicable under DASR and should be treated in accordance with DASR 21.A.3A. Such documents should be assessed for applicability to the ADF type design by the holder of the airworthiness authorisation listed in DASR 21.A.3A(a). Those documents assessed as applicable should be further treated in accordance with DASR 21.A.3A(b) and DASR 21.A.3A(c) to this regulation.

As a minimum, the holder of an airworthiness authorisation listed in DASR 21.A.3A(a) should monitor relevant information issued by any aviation authority whose prior certification was recognised by DASA in issuing that authorisation.

AMC2 to 21.A.3A(a) Collection, investigation and analysis of data related to DLRO significant occurrences

Holders of a type-certificate, restricted type-certificate, supplemental type-certificate or any other relevant approval deemed to have been issued under DASR 21 and which includes Defence Long Range Operation (DLRO) capability should implement a specific tracking, reporting and resolution system for DLRO significant occurrences, suitable to ensure the initial and continued fleet compliance with the applicable DLRO reliability objectives. This system should be part of the system for collection, investigation and analysis of data required by DASR 21.A.3A(a).

Appropriate coordination should exist between engine TC holder, propeller TC holder and APU MTSO authorisation holder with the aircraft TC holder to ensure compliance with the DLRO reliability objectives.

Reserved

AMC1 21.A.3A(a) System for collection, investigation and analysis of data for structure and propulsion systems (AUS).

Some risks and hazards associated with the type design may only become evident from a longer-term view of relevant data. The system for collecting, investigating and analysing reports of, and information related to, failures, malfunctions, defects or other occurrences should therefore include longer-term aggregation, trending and analysis of such reports and information.

Investigation and analysis should compare failures, malfunctions, defects and other occurrences with the design and certification assumptions to ensure that the type certificate continues to comply with the applicable Type Certification Basis and that the risk of failure has been eliminated or otherwise minimised SFARP. This may identify the need to change the type certificate, including new/amended operating limitations or new/amended airworthiness limitations (see DASR AMC 21.A.41), or revise the Instructions for Continuing Airworthiness furnished to operators (see DASR 21.A.61, DASR 21.A.107, DASR 21.A.120 and DASR 21.A.449).

For aircraft structure and propulsions systems, longer-term aggregation, trending and analysis of relevant failures, malfunctions, defects and other occurrences should be conducted through the Aircraft Structural Integrity Program (ASIP) and Propulsion System Integrity Program (PSIP) for each aircraft (see DASR 21.A.44(c)). Investigation and analysis of failures, malfunctions, defects and other occurrences for aircraft structure and propulsion systems also often requires specific skills due to the complex nature of these systems and their associated failure modes, and the specialised design methods and tools typically employed. Each failure, malfunction, defect or other occurrence related to aircraft structure and propulsion systems should therefore be promptly collected, investigated and analysed using the expertise available within the ASIP, PSIP and / or the responsible design organisation (if separate).

AMC 21.A.3A(a) - Collection, investigation and analysis of data related to Flammability Reduction Means (FRM) reliability

Holders of a type-certificate, restricted type-certificate, supplemental type-certificate or any other relevant approval deemed to have been issued under DASR 21 and which have included an FRM in their design should assess on an on-going basis the effects of aeroplane component failures on FRM reliability. This should be part of the system for collection, investigation and analysis of data required by DASR 21.A.3A(a). The applicant/holder should do the following:

Demonstrate effective means to ensure collection of FRM reliability data. The means should provide data affecting FRM reliability, such as component failures.

Unless alternative reporting procedures are approved by the Authority, provide a report to the Authority every six months for the first five years after service introduction. After that period, continued reporting every six months may be replaced with other reliability tracking methods found acceptable to the Authority or eliminated if it is established that the reliability of the FRM meets, and will continue to meet, the exposure specifications as defined by the applicable airworthiness requirements.

Develop service instructions or revise the applicable aeroplane manual, according to a schedule approved by the Authority, to correct any failures of the FRM that occur in service that could increase any fuel tanks Fleet Average Flammability Exposure to more than that specified by the applicable airworthiness requirements.

The holder of a type certificate, restricted type certificate, supplemental type certificate, Australian Military Technical Standard Order (AUSMTSO) authorisation, major repair design approval or any other relevant approval deemed to have been issued under this DASR shall have a system for collecting, investigating and analysing reports of and information related to failures, malfunctions, defects or other occurrences which cause or might cause adverse effects on the airworthiness of the product, part or appliance covered by the type-certificate, restricted type-certificate, supplemental type-certificate, AUSMTSO authorisation, major repair design approval or any other relevant approval deemed to have been issued under this DASR. Information about this system shall be made available to all known operators of the product, part or appliance and, on request, to any person authorised under other associated DASR.

Reporting to the Authority. GMGM GM1GM1

GM1 21.A.3A(b) - Occurrence reporting (AUS)

Relevant design organisations are to independently report on the occurrences to the Authority, with a focus on impact to the on-going validity of the certified design.

Typically, relevant design organisations will be made aware of occurrences by DASR 145 and Continuing Airworthiness Management Organisations (CAMO) fulfilling their reporting requirements.

However, in the course of conduct of design activities, analysis or relevant Military Type-certificate holder obligations, identified occurrences are to be reported to the Authority. These instances may not have a corresponding DASR 145 or CAMO Occurrence Report.

A list of occurrences to be reported are detailed in AMC GR.40 - Occurrence Reporting. This is not a comprehensive list and an additional requirement may need to be considered dependent on the scope of the organisations operations.

The following Sections are the most relevant to DASR 21:

SECTION I: AIRCRAFT FLIGHT OPERATIONS

SECTION II: AIRCRAFT TECHNICAL

SECTION V: IMMEDIATE NOTIFICATION OF ACCIDENTS AND SERIOUS INCIDENTS

In particular:

The products and part and appliances design rules prescribe that occurrences defined as a failure, malfunction, defect or other occurrence which has resulted in or may result in an unsafe condition must be reported to the Authority;

According to the product and part and appliances production rules occurrences defined as a deviation which could lead to an unsafe condition must be reported to the Authority.

GM 21.A.3A(b) Occurrence reporting

For occurrence reporting, additional guidance material can be found in EASA AMC 20-8, (part of EASA AMC 20 document) together with the military specific considerations that can be found in EMAD 20-8 (part of EMAD 20).

In particular:

The products and part and appliances design rules prescribe that occurrences defined as a failure, malfunction, defect or other occurrence which has resulted in or may result in an unsafe condition must be reported to the Authority;

According to the product and part and appliances production rules occurrences defined as a deviation which could lead to an unsafe condition must be reported to the Authority.

The holder of a type certificate, restricted type certificate, supplemental type certificate, AUSMTSO authorisation, major repair design approval or any other relevant approval deemed to have been issued under this DASR, shall report to the issuing / approving Authority any failure, malfunction, defect or other occurrence of which it is aware related to a product, part or appliance covered by the type certificate, restricted type certificate, supplemental type certificate, AUSMTSO authorisation, major repair design approval or any other relevant approval deemed to have been issued under this DASR, and which has resulted in or may result in an unsafe condition.

These reports shall be made in a form and manner established by the Authority, as soon as practicable and in any case dispatched not later than 72 hours after the identification of the possible unsafe condition, unless exceptional circumstances prevent this. AMCAMC AMC1AMC1

AMC1 21.A.3A(b)(2) - Reporting to the Authority (AUS)

Occurrence Reports may be transmitted by any method, however the preferred method is using the DASR Form 44 - Occurrence Report.

Urgent unsafe conditions should be reported by the fastest possible means, ie via telephone, in the first instance. All reporting should be followed up by a written report, within 72 hours.

The occurrence reporting process, content and format should be defined in the relevant organisation exposition or handbook.

Each report should contain at least the following information:

organisation details,

information necessary to identify the subject aircraft and/or products, parts and appliances affected, including software version (if applicable),

details of the occurrence,

implications to on-going validity of the type design (recommended), as to whether an unsafe condition exists, and

any other relevant information.

AMC 21.A.3A(b)(2) - Reporting to the Authority

Within the overall limit of 72 hours the degree of urgency for submission of a report should be determined by the level of hazard judged to have resulted from the occurrence.

Where an occurrence is judged by the person identifying the possible unsafe condition to have resulted in an immediate and particularly significant hazard the Authority expects to be advised immediately and by the fastest possible means of whatever details are available at that time. This initial report should be followed up by a full written report within 72 hours. A typical example would be an uncontained engine failure resulting in damage to aircraft primary structure.

Where the occurrence is judged to have resulted in a less immediate and less significant hazard, report submission may be delayed up to the maximum of three days in order to provide more details.

Investigation of Reported Occurrences.

When an occurrence reported under paragraph (b), or under DASR 21.A.129(f)(2) or DASR 21.A.165(f)(2) results from a deficiency in the design, or a manufacturing deficiency, the holder of the type-certificate, restricted type-certificate, supplemental type-certificate, AUSMTSO authorisation, major repair design approval or any other relevant approval deemed to have been issued under this DASR, or the manufacturer (Production Organisation) as appropriate, shall investigate the reason for the deficiency and report to the Authority the results of its investigation and any action it is taking or proposes to take to correct that deficiency.

If the Authority finds that an action is required to correct the deficiency, the holder of the type-certificate, restricted type-certificate, supplemental type-certificate, AUSMTSO authorisation, major repair design approval or any other relevant approval deemed to have been issued under this DASR, or the manufacturer as appropriate, shall submit the relevant data to the Authority.

21.A.3B - Airworthiness Directives

An Airworthiness Directive means a document issued or adopted by the Authority which mandates actions to be performed on an aircraft to restore an acceptable level of safety, when evidence shows that the safety level of this aircraft may otherwise be compromised. GMGM

GM 21.A.3B(a) - Airworthiness Directives (AUS)

The Authority will issue all Airworthiness Directives. In some circumstances the Authority’s issuing function may be conducted by a Delegate of the Safety Authority (DoSA) within the scope of their delegation.

The Authority shall issue an airworthiness directive when: AMCAMC GMGM

GM 21.A.3B(b) - Determination of an unsafe condition

It is important to note that these guidelines are not exhaustive. However, this material is intended to provide guidelines and examples that will cover most cases, taking into account the applicable certification requirements.

1. INTRODUCTION

Certification or approval of a product, part or appliance is a demonstration of compliance with requirements which are intended to ensure an acceptable level of safety. This demonstration however includes certain accepted assumptions and predicted behaviours, such as:

fatigue behaviour is based on analysis supported by test,

modelling techniques are used for Aircraft Flight Manual (AFM) performances calculations,

the systems safety analyses give predictions of what the systems failure modes, effects and probabilities may be,

the system components reliability figures are predicted values derived from general experience, tests or analysis,

the crew is expected to have the skill to apply the procedures correctly, and

the aircraft is assumed to be maintained in accordance with the prescribed instructions for continuing airworthiness (or maintenance programme), etc.

In service experience, additional testing, further analysis, etc., may show that certain initially accepted assumptions are not correct. Thus, certain conditions initially demonstrated as safe, are revealed by experience as unsafe. In this case, it is necessary to mandate corrective actions in order to restore a level of safety consistent with the applicable certification requirements.

See DASR AMC 21.A.3B(b) for definition of 'unsafe condition' used in DASR 21.A.3B(b).2.

2. GUIDELINES FOR ESTABLISHING IF A CONDITION IS UNSAFE

The following paragraphs give general guidelines for analysing the reported events and determining if an unsafe condition exists, and are provided for each type of product, part or appliance subject to a specific airworthiness approval: Military Type-Certificates (MTC) or Military Supplemental Type-Certificates (MSTC) for aircraft, engines or propellers, or Australian Military Technical Standard Orders ( AUSMTSO ).

This analysis may be qualitative or quantitative, i.e. formal and quantitative safety analyses may not be available for older or small aircraft. In such cases, the level of analysis are to be consistent with that required by the airworthiness requirements and may be based on engineering judgement supported by service experience data.

2.1 Analysis method for aircraft

2.1.1 – Accidents or incidents without any aircraft, engines, system, propeller or part or appliance malfunction or failure

When an accident/incident does not involve any component malfunction or failure but when a crew human factor has been a contributing factor, this has to be assessed from a human-machine interface standpoint to determine whether the design is adequate or not. Paragraph 2.5 gives further details on this aspect.

2.1.2 – Events involving an aircraft, engines, system, propeller or part or appliance failure, malfunction or defect

The general approach for analysis of in service events caused by malfunctions, failures or defects will be to analyse the actual failure effects, taking into account previously unforeseen failure modes or improper or unforeseen operating conditions revealed by service experience.

These events may have occurred in service, or have been identified during maintenance, or been identified as a result of subsequent tests, analyses, or quality control.

These may result from a design deficiency or a production deficiency (non-conformity with the type design), or from improper maintenance. In this case, it has to be determined if improper maintenance is limited to one aircraft, in which case an airworthiness directive may not be issued, or if it is likely to be a general problem due to improper design and/or maintenance procedures, as detailed in paragraph 2.5.

2.1.2.1 – Flight

An unsafe condition exists if:

There is a significant shortfall of the actual performance compared to the approved performance (taking into account the accuracy of the performance calculation method), or

The handling qualities, although having been found to comply with the applicable airworthiness requirements at the time of initial approval, are subsequently shown by service experience not to comply.

2.1.2.2 – Structural or mechanical systems

An unsafe condition exists if the deficiency may lead to a structural or mechanical failure which:

Could exist in a Principal Structural Element that has not been qualified as damage tolerant. Principal Structural Elements are those which contribute significantly to carrying flight, ground, and pressurisation loads, and whose failure could result in a catastrophic failure of the aircraft.

Typical examples of such elements are listed, as guidance, in EASA Certification Specification for Large Aircraft (CS–25) AMC 25.571(a) 'damage tolerance and fatigue evaluation of structure', and in the equivalent material for rotorcraft.

Could exist in a Principal Structural Element that has been qualified as damage tolerant, but for which the established inspections, or other procedures, have been shown to be, or may be, inadequate to prevent catastrophic failure.

Could reduce the structural stiffness to such an extent that the required flutter, divergence or control reversal margins are no longer achieved.

Could result in the loss of a structural piece that could damage vital parts of the aircraft, cause serious or fatal injuries to persons other than occupants.

Could, under ultimate load conditions, result in the liberation of items of mass that may injure occupants of the aircraft.

Could jeopardise proper operation of systems and may lead to hazardous or catastrophic consequences, if this effect has not been taken adequately into account in the initial certification safety assessment.

2.1.2.3 – Systems

The consequences of reported systems components malfunctions, failures or defects are to be analysed.

For this analysis, the certification data may be used as supporting material, in particular systems safety analyses.

The general approach for analysis of in service events caused by systems malfunctions, failures or defects will be to analyse the actual failure effects.

As a result of this analysis, an unsafe condition will be assumed if it cannot be shown that the safety objectives for hazardous and catastrophic failure conditions are still achieved, taking into account the actual failure modes and rates of the components affected by the reported deficiency.

The failure probability of a system component may be affected by:

A design deficiency (the design does not meet the specified reliability or performance);

A production deficiency (non-conformity with the certified type design) that affects either all components, or a certain batch of components;

Improper installation (for instance, insufficient clearance of pipes to surrounding structure);

Susceptibility to adverse environment (corrosion, moisture, temperature, vibrations etc.);

Ageing effects (failure rate increase when the component ages);

Improper maintenance.

When the failure of a component is not immediately detectable (hidden or latent failures), it is often difficult to have a reasonably accurate estimation of the component failure rate since the only data available are usually results of maintenance or flight crew checks. This failure probability is therefore be conservatively assessed.

As it is difficult to justify that safety objectives for the following systems are still met, a deficiency affecting these types of systems may often lead to a mandatory corrective action:

Back up emergency systems, or

Fire detection and protection systems (including shut off means).

Deficiencies affecting systems used during an emergency evacuation (emergency exits, evacuation assist means, emergency lighting system ...) and to locate the site of a crash (Emergency Locator Transmitter) will also often lead to mandatory corrective action.

2.1.2.4 – Others

In addition to the above, the following conditions are considered unsafe:

There is a deficiency in certain components which are involved in fire protection or which are intended to minimise/retard the effects of fire / smoke in a survivable crash, preventing them to perform their intended function (for instance, deficiency in cargo liners or cabin material leading to non-compliance with the applicable flammability requirements).

There is a deficiency in the lightning or High Intensity Radiated Fields protection of a system which may lead to hazardous or catastrophic failure conditions.

There is a deficiency which could lead to a total loss of power or thrust due to common mode failure.

If there is a deficiency in systems used to assist in the enquiry following an accident or serious incident, eg Cockpit Voice Recorder, Flight Data Recorder, preventing them to perform their intended function, the Authority may take mandatory action.

2.2 Engines

The consequences and probabilities of engine failures have to be assessed at the aircraft level in accordance with paragraph 2.1, and applicable airworthiness requirements. Further guidance at the engine level for those failures considered as hazardous can be found in CS–E–510 under EASA Certification Specification – Engines (CS–E).

The latter will be assumed to constitute unsafe conditions, unless it can be shown that the consequences at the aircraft level do not constitute an unsafe condition for a particular aircraft installation.

2.3 Propellers

The consequences and probabilities of propeller failures have to be assessed at the aircraft level in accordance with paragraph 2.1, and applicable airworthiness requirements. Further guidance at the propeller level for those failures considered as hazardous can be found in CS–P–70 under EASA Certification Specification – Propellers (CS–P).

The latter will be assumed to constitute unsafe conditions, unless it can be shown that the consequences at the aircraft level do not constitute an unsafe condition for a particular aircraft installation.

2.4 Parts and appliances

The consequences and probabilities of equipment failures have to be assessed at the aircraft level in accordance with paragraph 2.1.

2.5 Human factors aspects in establishing and correcting unsafe conditions

This paragraph provides guidance on the way to treat an unsafe condition resulting from a maintenance or crew error observed in service.

It is recognised that human factors techniques are under development. However, the following is a preliminary guidance on the subject.

Systematic review is to be used to assess whether the crew or maintenance error raises issues that require regulatory action (whether in design or other areas), or is to be noted as an isolated event without intervention. This may need the establishment of a multidisciplinary team (designers, crews, human factors experts, maintenance experts, operators etc.)

The assessment is to include at least the following:

Characteristics of the design intended to prevent or discourage incorrect assembly or operation;

Characteristics of the design that allow or facilitate incorrect operation;

Unique characteristics of a design feature differing from established design practices;

The presence of indications or feedback that alerts the operator to an erroneous condition;

The existence of similar previous events, and whether or not they resulted (on those occasions) in unsafe conditions;

Complexity of the system, associated procedures and training (has the crew a good understanding of the system and its logic after a standard crew qualification programme?);

Clarity / accuracy / availability / currency and practical applicability of manuals and procedures;

Any issues arising from interactions between personnel, such as shift changeover, dual inspections, team operations, supervision (or lack of it), or fatigue.

Apart from a design change, the corrective actions, if found necessary, may consist of modifications of the manuals, inspections, training programmes, and/or information to the operators about particular design features. The Authority may decide to make mandatory such corrective action if necessary.

AMC 21.A.3B(b) - Unsafe condition

An unsafe condition exists if there is factual evidence (from service experience, analysis or tests) that:

An event may occur that would result in fatalities, usually with the loss of the aircraft, or reduce the capability of the aircraft or the ability of the crew to cope with adverse operating conditions to the extent that there would be:

A large reduction in safety margins or functional capabilities, or

Physical distress or excessive workload such that the flight crew cannot be relied upon to perform their tasks accurately or completely, or

Serious or fatal injury to one or more occupants,

unless it is shown that the probability of such an event is within the limit defined by the applicable airworthiness requirements, or

There is an unacceptable risk of serious or fatal injury to persons other than occupants, or

Design features intended to minimise the effects of survivable accidents are not performing their intended function.

NOTE 1: Non-compliance with applicable airworthiness requirements is generally considered as an unsafe condition, unless it is shown that possible events resulting from this non-compliance do not constitute an unsafe condition as defined under paragraphs (a), (b) and (c).

NOTE 2: An unsafe condition may exist even though applicable airworthiness requirements are complied with.

NOTE 3: The above definition covers the majority of cases where the Authority considers there is an unsafe condition. There may be other cases where overriding safety considerations may lead the Authority to issue an airworthiness directive.

NOTE 4: There may be cases where events can be considered as an unsafe condition if they occur too frequently (significantly beyond the applicable safety objectives) and could eventually lead to consequences listed in paragraph a) in specific operating environments. Although having less severe immediate consequences than those listed in paragraph a), the referenced events may reduce the capability of the aircraft or the ability of the crew to cope with adverse operating conditions to the extent that there would be, for example, a significant reduction in safety margins or functional capabilities, a significant increase in crew workload, or in conditions impairing crew efficiency, or discomfort to occupants, possibly including injuries.

an unsafe condition has been determined by the Authority to exist in an aircraft, as a result of a deficiency in the aircraft, or an engine, propeller, part or appliance installed on this aircraft; and

that condition is likely to exist or develop in other aircraft, including engine, propeller, part or appliance installed on those aircraft that may be affected by this unsafe condition.

When an Airworthiness Directive has to be issued by the Authority to correct the unsafe condition referred to in paragraph (b), or to require the performance of an inspection, the holder of the type-certificate, restricted type-certificate, supplemental type-certificate, major repair design approval, AUSMTSO authorisation or any other relevant approval deemed to have been issued under this DASR, shall:

propose the appropriate corrective action and/or required inspections and submit details of these proposals to the Authority for approval; AMC1AMC1 AMC2AMC2

AMC2 21.A.3B(c)(1) - Airworthiness Directives for aircraft structures and propulsion systems (AUS)

For unsafe conditions related to structures and propulsion systems the proposed corrective actions and inspections should take into account the following specific considerations in addition to those of DASR AMC1 21.A.3B(c)(1).

AIRCRAFT STRUCTURE

The proposed corrective actions and inspections should be based on conservative engineering analysis and judgement. The proposal submitted to the Authority by the holder should include:

Relevant assumptions and details of the analysis performed.

Justification that the proposed corrective actions and inspections eliminate or otherwise minimise the risk(s) SFARP.

Most airworthiness design standards for structures are based on deterministic criteria, and it follows that proposed corrective actions and inspections will often be based on similar methods. Therefore, the guidance on compliance time under DASR 21.A.3B(d)(4) will usually not be suitable for aircraft structures unless probabilistic methods are used in development of the proposed corrective actions and inspections. Where probabilistic methods are not used, compliance times should be established using conservative analysis and judgement.

PROPULSION SYSTEMS

The proposed corrective actions and inspections should be based on:

FAA AC 39–8 - Continued Airworthiness Assessment Methodologies (CAAM), or

conservative engineering analysis and judgement.

The proposal submitted to the Authority by the holder should include:

Relevant assumptions and input data (including fleet data and statistical model parameters).

Risk profile over the full duration of the fleet management strategy.

Justification that the proposed corrective actions and inspections eliminate or otherwise minimise the risk(s) SFARP

The application of FAA AC 39–8 for determining compliance time of corrective actions and inspections will typically require detailed design data and complex statistical and probabilistic analyses. The Authority expects that the propulsion system OEM will normally be involved in this process.

AMC1 21.A.3B(c)1 - Airworthiness Directives (AUS)

Corrective actions and inspections that are proposed by the holder are to eliminate all risks associated with the unsafe condition So Far As is Reasonably Practicable (SFARP), or if it is not reasonably practicable to do so, minimise the risk(s) SFARP. To fulfil this requirement, the holder should ensure that the safety risk management requirements outlined in DASR SMS.A.25(b)(2)(2.2) are applied for all safety related risks.

Foreign Airworthiness Directives

The holder may submit an AD, or equivalent, in support of the proposed corrective action where the Airworthiness Directive (AD) addresses the unsafe condition referred to in DASR 21.A.3B(b) and:

has been issued by an aviation authority whose certifications are recognised by DASA, and

has been assessed as applicable to the ADF type design in accordance with DASR AMC2 21.A.3A(a).

following the approval by the Authority of the corrective action and/or required inspections referred to under subparagraph (c)1, make available to all known operators or owners of the product, part or appliance and, on request, to any person required to comply with the airworthiness directive, appropriate descriptive data and accomplishment instructions.

An Airworthiness Directive shall contain at least the following information:

an identification of the unsafe condition;

an identification of the affected aircraft; operating and maintenance associated documentation;

the action(s) required;

the compliance time for the required action(s); GMGM

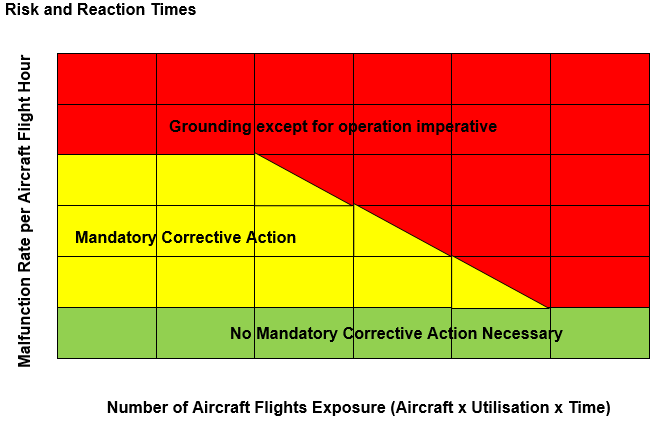

GM 21.A.3B(d)(4) - Compliance time charts for military aircraft

If it is not possible to find mitigations and/or limitations that re-establish compliance with all the applicable safety requirements, an increased risk for an individual failure could be acceptable for a fixed period of time if it is demonstrated that during this period the cumulative probability of catastrophic event per flight hour is still compliant with the type-certification basis.

Exceptions are possible in accordance with National regulations.

The residual risk during the time allowed to fix the defect is to be identified and minimized. Risk assessment techniques could be used to establish the deadline period to fix defects as agreed by the National Authority.

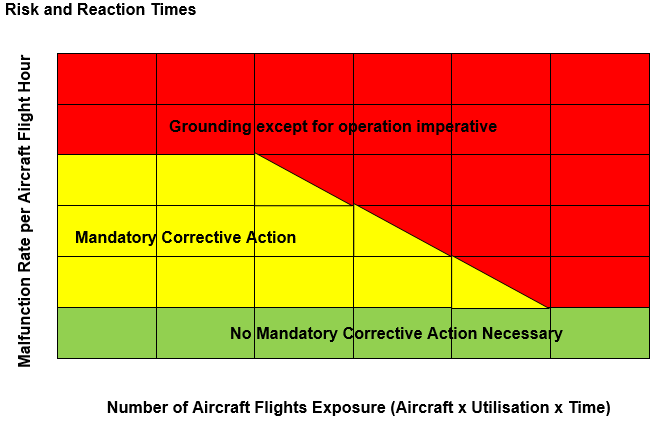

The civil regulations EASA Part 21 (21.A.3B) allow a time period that is directly related to the level risk i.e. higher the risk the shorter the time period. These regulations have hard limits for the maximum instantaneous risk, the maximum risk for an individual aircraft and maximum cumulative risk for the fleet. The basis of these regulations considers typical civil operation, of 10 major safety campaigns during an aircraft life, a hull life of 60,000 hours and that 75% of the risk is attributed to the design. Using the above assumptions they calculate an acceptable time period for restoration of risk levels to certification levels.

For military aircraft the above assumptions are not necessarily valid and the acceptable levels of risk likely to be different, however the principles of the civil system can be equally applied to the military regulations. The graphical representation below, on a logarithmic scale, is adapted from civil regulations AMC to EASA Part 21.A.3B, without the numerical limits, and can be used to enable the Authority (where national regulations allow) to determine appropriate numerical limits, considering the role of the aircraft. There will be different limits for Catastrophic and Hazardous failures.

the date of entry into force.

21.A.4 - Co-ordination between design and production

AMCAMC

AMC 21.A.4 - Transferring of information on eligibility and approval status from the design organisations to production organisations

Where there is a need to provide (normally outside the design organisation) a visible statement of approved design data or airworthiness, operational suitability or environmental protection data associated with the approved design data, the following minimum information should be provided. The need for a visible statement may be in relation to Company holding a military production organisation approval (MPOA) in relation to DASR 21.A.163(c).

The procedures related to the use of forms or other electronic means to provide this information should be agreed with the Authority.

Information to be provided:

Company Name: the name of the responsible design organisation (MTC, MSTC, approval of repair or minor change design, AUSMTSO authorisation holder) issuing the information.

Date: the date at which the information is released.

Eligibility: indicate the specific products or articles, in case of AUSMTSO authorisation, for which data have been approved.

Identification: the part number of the part or appliance. Preference should be given to the use of the Illustrated Parts Catalogue (IPC) designation. Alternatively the reference to the instruction for continuing airworthiness could be stated. Marking requirements of DASR 21 Section A Subpart Q should be taken into account.

Description: the name or description of the part or document should be given. In the case of a part or appliance preference should be given to use of IPC designation. The description is to include reference to any applicable AUSMTSO authorisation or AUSMPA marking, or previous national approvals still valid.

Purpose of data: the reason for the provision of the information should be stated by the design approval holder.

Examples:

-

Provision of approved design data to a production organisation to permit manufacture (AMC1 to 21.A.133(b) and AMC1 to 21.A.133(c))

-

Information regarding eligibility for installation (replacement parts, repair, modification, etc.)

-

Direct Delivery Authorisation (AMC1 to 21.A.133(b) and AMC1 to 21.A.133(c)).

If the data is in support of a change or repair, then reference to the aircraft level approval should be given (make reference to the approved MSTC, change or repair).

Limitations/Remarks: state any information, either directly or by reference to supporting documentation that identifies any particular data or limitations (including specific importing requirements) needed by a production organisation to complete Block 12 of the DASR Form 1—Authorised Release Certificate.

Approval: provide reference information related to the approval of the data (Authority document or MDOA privilege).

Authorised signature: name and hand-written normal or electronic signature of a person who has written authority from the design organisation, as indicated in the procedures agreed with the Authority.

Each holder of a type-certificate, restricted type-certificate, supplemental type-certificate, AUSMTSO authorisation, approval of a change to type certificate or approval of a repair design, shall ensure collaboration between the design organisation and the production organisation as necessary to achieve:

The satisfactory coordination of design and production required by DASR 21.A.122, DASR 21.A.130(b)(3) and (b)(4), DASR 21.A.133 or DASR 21.A.165(c)(2) and (c)(3), as appropriate; and

The proper support of the continued airworthiness of the product, part or appliance.

SUBPART B - MILITARY TYPE-CERTIFICATES AND MILITARY RESTRICTED TYPE-CERTIFICATES

21.A.11 - Scope

This Subpart establishes the procedure for issuing Military Type-Certificates (MTCs) for products and Military Restricted Type-Certificates (MRTCs) for aircraft, and establishes the rights and obligations of the applicants for, and holders of, those certificates.

21.A.13 - Eligibility

Any organisation that has demonstrated, or is in the process of demonstrating, its capability in accordance with DASR 21.A.14 shall be eligible as an applicant for a type-certificate or a restricted type-certificate under the conditions laid down in this Subpart.

21.A.14 - Demonstration of capability

Any organisation applying for a type-certificate or restricted type-certificate shall demonstrate its capability by holding a military design organisation approval (MDOA), issued by the Authority in accordance with DASR 21 Subpart J.

By way of exception from paragraph (a), as an alternative procedure to demonstrate its capability, an applicant may seek Authority agreement for the use of procedures setting out the specific design practices, resources and sequence of activities necessary to comply with this DASR, under the following: AMCAMC GMGM

GM 21.A.14(b) - Eligibility for alternative procedures

Design organisations approved under DASR 21 Section A Subpart J ("Subpart J MDOA") is to be the normal approach for military type-certification, military supplemental type-certification, approval of major changes to type design or approval of major repair design, except when agreed otherwise by the Authority in accordance with DASR 21.A.14, DASR 21.A.112B and DASR 21.A.432B.

The acceptance of alternative procedures, as defined in DASR AMC 21.A.14(b), is to be limited where the Authority finds it more appropriate for the conduct of military type-certification, military supplemental type-certification, approval of changes to type design, approval of repair design.

Products with simple or limited scope of design

As the complexity of a product grows, so does the size of a design organisation, along with an increasing degree of specialisation of various parts of the organisation to meet the growing demands of different disciplines. This creates complex communication relationships and workflows.

‘Simple or limited scope of design’ should therefore be understood as the opposite of ‘complex’, see also DASR AMC 21.A.15(b)(6) Level of involvement (LoI).

When determining the complexity of the scope of design, the complexity of the product as well as the structure of the design organisation and relationships with suppliers should be considered.

AMC 21.A.14(b) ‐ Alternative procedures

Alternative procedures are an acceptable means to demonstrate design capability in the cases described in DASR 21.A.14, DASR 21.A.112B, or DASR 21.A.432B. In the context of specific projects, the implementation of procedures required for a design organisation approval in accordance with DASR 21 Subpart J will ensure that the applicant performs the relevant activities as expected by the Authority. The establishment of these alternative procedures may be seen as a starting phase for a Subpart J MDOA, allowing at a later stage, at the discretion of the applicant, to move towards a full Subpart J MDOA by the addition of the missing elements.

1. Scope

1.1 As alternative to MDOA, a manual of procedures should set out specific design practices, resources and sequence of activities relevant for the specific projects, taking account of DASR 21 requirements.

1.2 These procedures should be concise and limited to the information needed for quality and proper control of activities by the applicant/holder, and by the Authority.

2. Management of the (supplemental) type-certification process

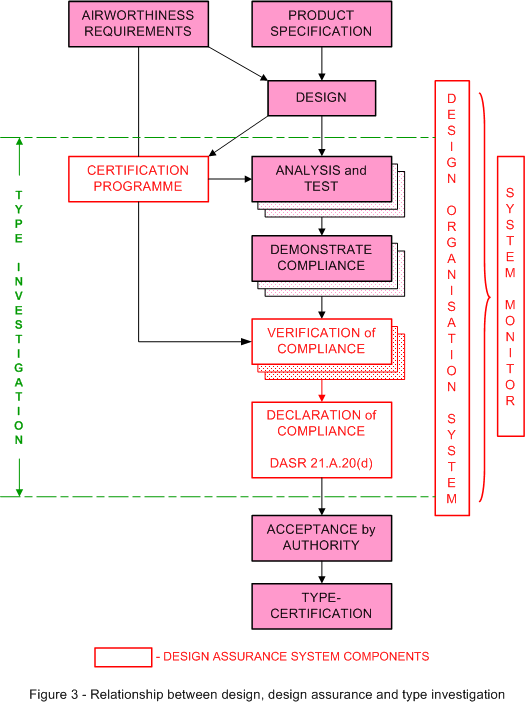

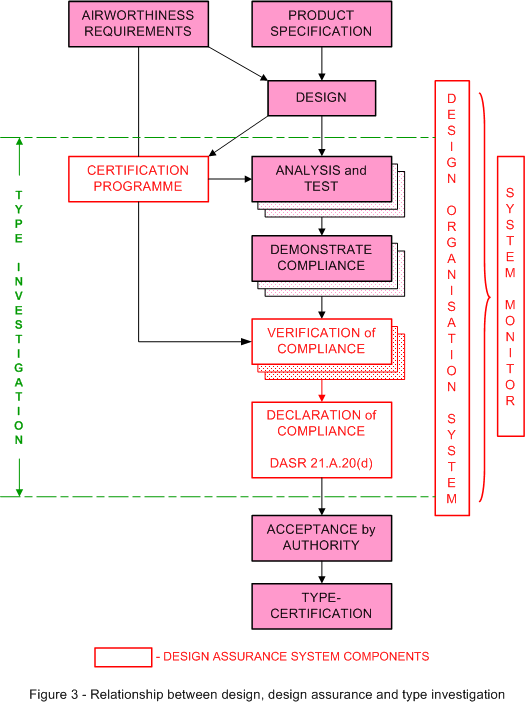

2.1 Certification Programme: See DASR AMC 21.A.15(b) for type-certification and DASR AMC 21.A.93(b) for supplemental type-certification.

2.2 Compliance demonstration: see DASR GM 21.A.20

2.3 Reporting: see DASR GM 21.A.20(b)

2.4 Compliance documentation: see DASR AMC 21.A.20(c).

2.5 Declaration of compliance: see GM 21.A.20(d)

3. Management of changes to type certificates, repair designs and production deviations

3.1 Management of changes to a type certificate or supplemental type certificate (hereinafter referred to as 'changes'), repair designs and production deviations from the approved design data

The applicant should provide procedures that are acceptable to the Authority for classification and approval of changes (see paragraphs 3.2 and 3.3), and repair designs and production deviations from the approved design data (see paragraph 3.4).

3.2 Classification

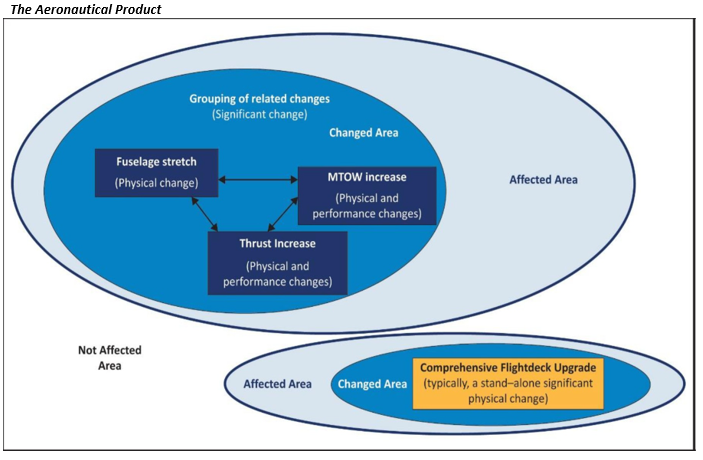

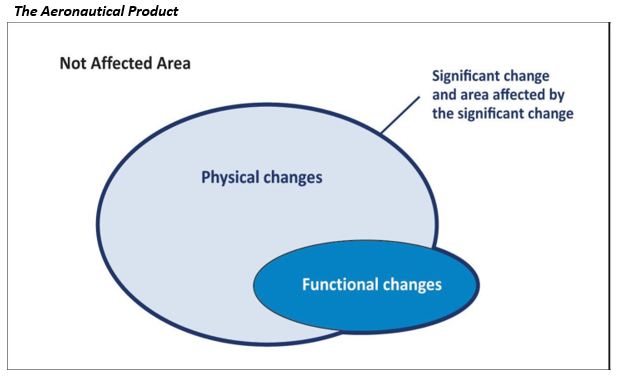

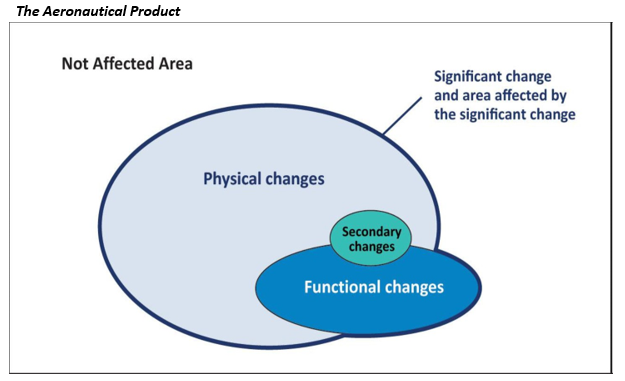

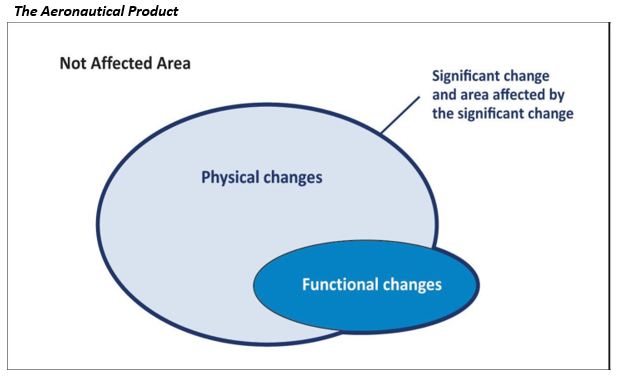

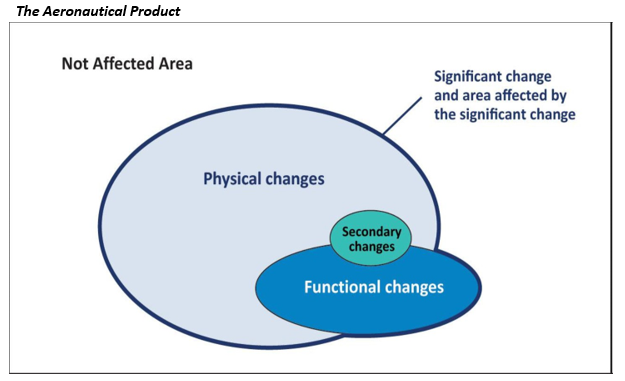

3.2.1 – Content

The procedure should address the following points:

the identification of the product configuration(s) to which the change is to be made,

the identification of the areas of the product that are changed or affected by the change,

the identification of any reinvestigations that are necessary (see DASR 21.A.93(b)(2)), including the identification of the applicable airworthiness requirements, or environmental protection requirements and means of compliance,

changes initiated by subcontractors;

documents to justify the classification;

authorised signatories.

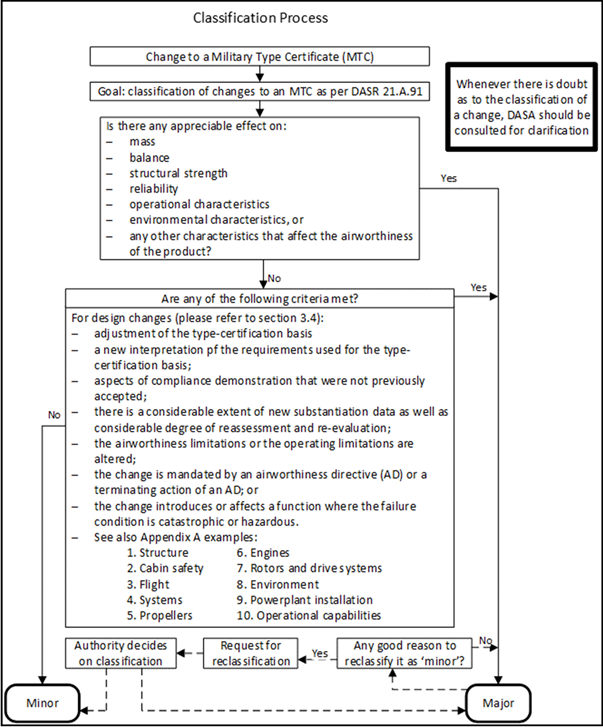

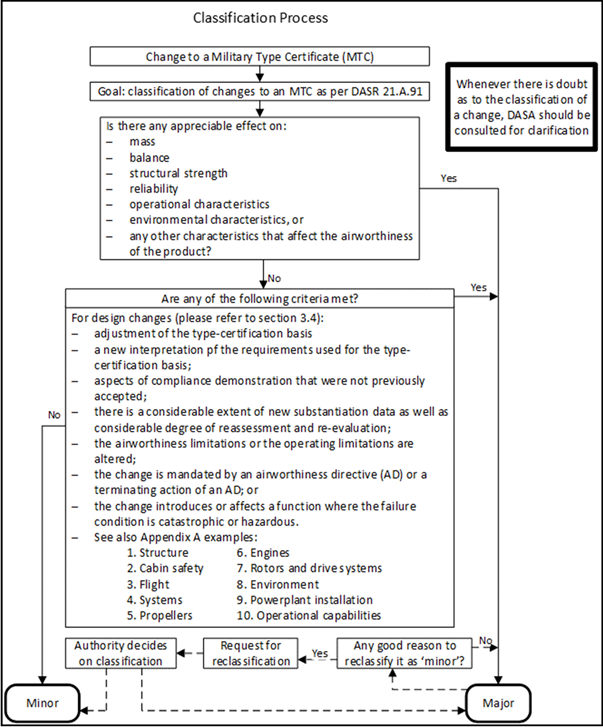

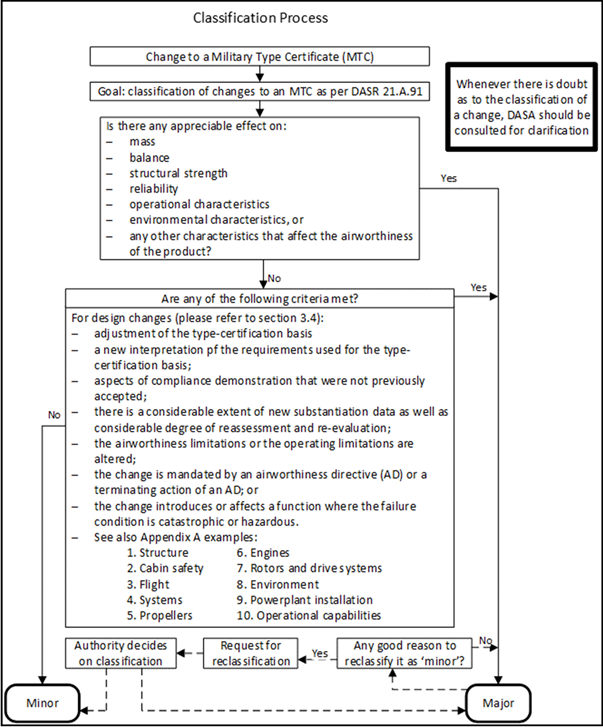

The criteria used for classification should be in compliance with DASR 21.A.91 and corresponding interpretations.

3.2.2 – Identification of changes

The procedure should indicate how the following are identified:

major changes;

those minor changes where additional work is necessary to demonstrate compliance with the airworthiness requirements;

other minor changes that require no further demonstration of compliance.

3.2.3 – Considerations of effects of the change

The procedure should show how the effects on airworthiness, operational suitability or environmental protection (where applicable) are analysed, from the very beginning, by reference to the applicable airworthiness requirements.

If no specific airworthiness requirements are applicable to the change, the above review should be carried out at the level of the part or system where the change is integrated and where specific airworthiness requirements are applicable.

3.2.4 – Control of changes initiated by subcontractors

The procedure should indicate, directly or by cross‐reference to written procedures, how changes initiated by subcontractors are controlled.

3.2.5 – Documents to justify the classification

All decisions of classification of changes should be documented and approved by the Authority. It may be in the format of meeting notes or register.

3.2.6 – Authorised signatories

The procedure should identify the persons authorised to sign the proposed classification before release to the Authority for approval.

3.3 Approval of changes

3.3.1 – Content

The procedure should address the following points:

compliance documentation;

approval process;

authorised signatories.

3.3.2 – Compliance documentation

For major changes and those minor changes where additional work to demonstrate compliance with the applicable type-certification basis, operational suitability data certification basis, and environmental protection requirements (hereinafter referred to as the ‘certification basis’) is necessary, compliance documentation should be established in accordance with DASR AMC 21.A.20(c).

3.3.3 – Approval process

A. For the approval of major changes, a certification programme as defined in DASR AMC 21.A.93(b) must be established.

B. For major changes and those minor changes where additional work to show compliance with the applicable certification basis is necessary, the procedure should define a document to support the approval process.

This document should include at least:

identification and brief description of the change and its classification;

references to the applicable certification basis;

references to the compliance documents;

effects, if any, on limitations and on the approved design data;

the name of the authorised signatory.

C. For the other minor changes, the procedure should define a means:

to identify the change;

to present the change to the Authority for approval.

3.3.4 – Authorised signatories

The procedure should identify the persons authorised to sign the change before release to the Authority for approval.

3.4 Repair designs and production deviations from the approved design data

A procedure following the principles of paragraphs 3.2 and 3.3 should be established for the classification and approval of repair designs and unintentional deviations from the approved design data occurring in production (concessions or non-conformance's). For repair designs, the procedure should be established in accordance with DASR 21 Section A Subpart M and associated acceptable means of compliance (AMC) or guidance material (GM).

4. Issue of data and information (including instructions) to owners, operating organisations and others required to use the data and information

4.1 General

Data and information include the operational suitability data.

4.2 Data related to changes

The data and information (including instructions) issued by the holder of a (military) design approval (an MTC, MSTC, approval of a change, approval of repair design) are intended to provide the owners of a product with all necessary data to implement a change or repair on the product, or to inspect it.

The data and information (including instructions) may be issued in a format of a Service Bulletin as defined in S1000D Chapters, or in structural repair manuThe data and information (including instructions) issued by the holder of a (military) design approval (an MTC, MSTC, approval of a change, approval of repair design) are intended to provide the owners of a product with all necessary data to implement a change or repair on the product, or to inspect it.als, Maintenance Manuals, Engine and Propeller Manuals, etc.

The preparation of this data involves design, production and inspection. The three aspects should be properly addressed and a procedure should exist.

4.3 Procedure

The procedure should address the following points:

preparation;

verification of technical consistency with corresponding approved change(s), repair design(s) or approved data, including effectivity, description, effects on airworthiness or operational suitability, especially when limitations are changed;

verification of the feasibility in practical applications;

approval for the release of the data and information.

The procedure should include the information or instructions prepared by subcontractors or vendors, and declared applicable to its products by the holder of the MTC, MSTC, approval of changes to type design or approval of repair design.

4.4 Statement

The data and information (including instructions) should contain a statement showing Authority approval.

5. Obligations addressed in DASR 21.A.44 (MTC holder), DASR 21.A.118A (STC holder) or DASR 21.A.451 (major repair design approval holder)

The applicant for alternative procedures to demonstrate their design capabilities should establish the necessary procedures to show to the Authority how it will fulfil the obligations required under DASR 21.A.44, DASR 21.A.118A or DASR 21.A.451, as appropriate.

6. Control of design subcontractors

The applicant for alternative procedures to demonstrate their design capabilities should establish the necessary procedures to show to the Authority how it will control design subcontractors and ensure the acceptability of the parts or appliances that are designed, or the design tasks that are performed.

Products with simple or limited scope of design.

Starting phase toward a military design organisation approval or limited duration of design activities.

Products for which the major part of the Type Design certification activities have already been accepted by the Authority concerned.

Reserved.

By way of exception from paragraph (a) and (b), any government organisation applying for a type-certificate or restricted type-certificate may demonstrate its capability by having an agreement in place, accepted by the Authority, in accordance with DASR 21.A.2 with a design organisation which has access to the type design data. The agreement shall include detailed statements how the actions and obligations are delegated to enable the government organisation, in cooperation with the contracted organisation, to comply with the requirements of DASR 21 Subpart J, including demonstration of compliance with DASR 21.A.44. AMCAMC AMC1AMC1 GMGM

GM 21.A.14(c) - MTC holder organisations (AUS)

Unlike civil TC obligations, Defence MTC and MRTC obligations are not enforceable via national legislation; DASR (in general) are enforceable for commercial organisations only via contract law. As a result, during the certification or approval process, the Authority will assess a nominated Australian government organisation, and when satisfied issue the Australian MTC to that organisation. That organisation becomes responsible for conduct of the holder obligations as detailed in DASR 21.A.44. DASR AMC 21.A.14(c) defines the assessment criteria for the MTC holder organisation that will conduct the holder responsibilities and manage major changes to the issued MTC or MRTC.

Contracting of holder responsibilities. Where the government organisation does not meet DASR 21.A.14(a) or (b) provisions, or is unable to meet all obligations internally DASR 21.A.14(c) allows for the government organisation to contract the provision of the DASR 21.A.44, DASR 21.A.118A and DASR 21.A.451(a) aligned holder obligations to commercial engineering organisations under DASR 21.A.2.

Where extant procurement/ support arrangements preclude a DASR MDO being contracted under these provisions, the holder organisation will need to use the DASA recognition framework to assist demonstration of the external design organisation as suitable to meet the DASR 21 Subpart J requirements and should also pay particular attention to the equivalence of obligations in the areas of major/minor design change classification (DASR 21.A.91) and reporting to the Authority of failures, malfunctions and defects (DASR 21.A.3A). This is to ensure that Authority interfaces are established at the same equivalent level and hence the Authority’s safety assurance function is not compromised by the incorrect translation of processes. Attention should also focus on the processes to meet the Safety Management System requirements (DASR 21.A.239(d)) equivalence. This is to ensure that the holder organisation’s risk management of operational hazards is based on a sound risk and safety management system.

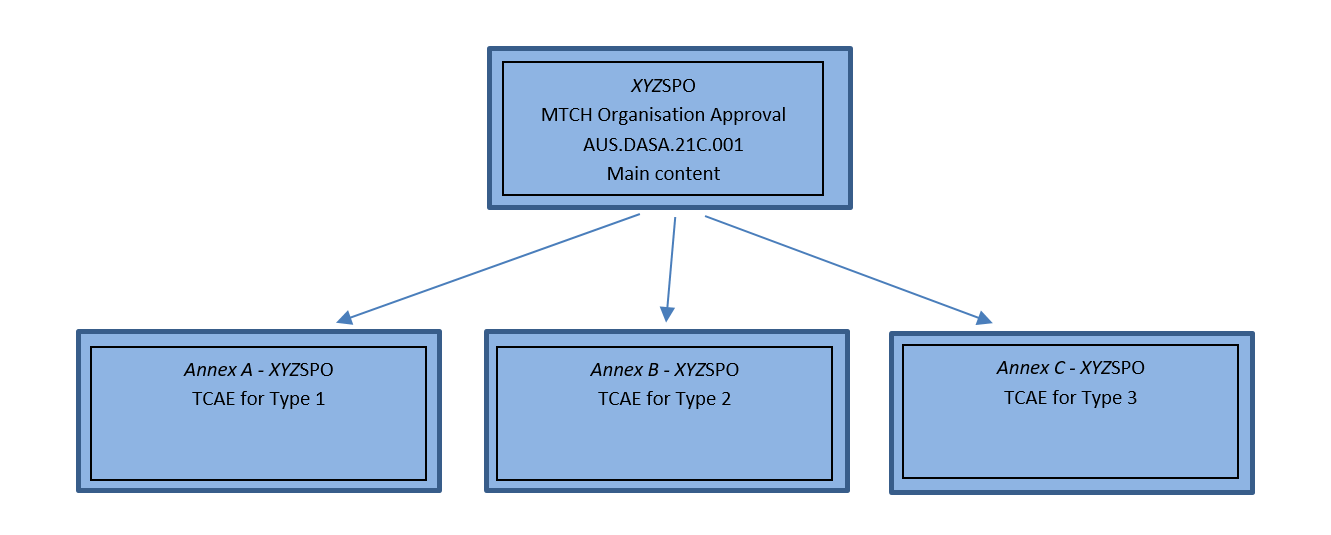

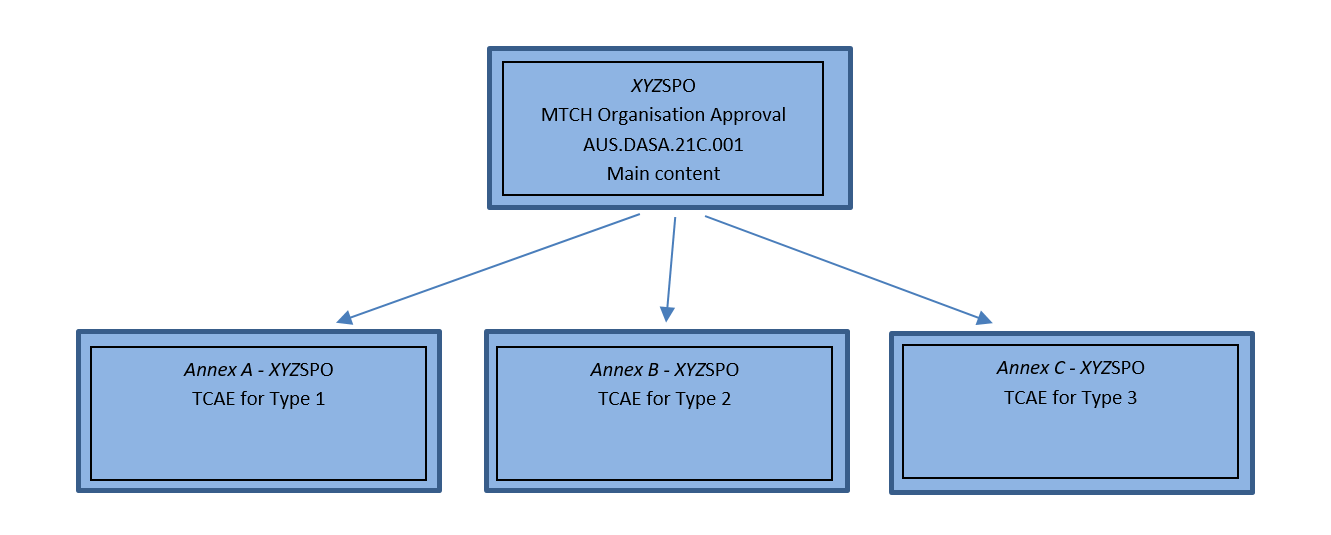

Application. During the Certification Program culminating in issue of a new MTC or MRTC the Project Office will identify an appropriate government organisation best placed to fulfil the DASR 21.A.44 holder obligations. The PO, in conjunction with the proposed MTC holder will develop an exposition, known as the Type Continued Airworthiness Exposition (TCAE), to show how compliance with the DASR 21J requirements and holder obligations is achieved.

Type Continued Airworthiness Exposition. The purpose of the TCAE is to inform the Authority of the proposed MTC holder management arrangements. The nature of those arrangements will vary considerably between aircraft types, and will depend on the product’s design itself; how the product is operated; and the depth and ability of organisations supporting the product’s design.

A TCAE satisfies the following needs:

Contains, or references to, the agreement that shows how the government organisation, in cooperation with the supporting design organisation(s) will comply with the requirements of DASR 21 Subpart J, including demonstration of compliance in meeting the holder obligation.

Provides confidence that the applicant government organisation understands the nature of the product’s design and its supporting organisations sufficiently to meet the holder obligations.

Identifies the senior Defence engineer responsible for oversighting delivery of the holder functions.

Provides key information influencing the specific solution to meet the MTC holder obligations, particularly where obligations are fulfilled via non-commercial arrangement, eg via foreign military sales or other global fleet support arrangement.

Is a working document able to expand to reflect arrangements for subsequent MTC Changes, MSTC issues, and major repair design approvals.

AMC1 21.A.14(c) - Alternative Demonstration (AUS)

MTC holder demonstration of capability

Government organisations seeking to become an MTC holder shall submit a Type Continued Airworthiness Exposition (TCAE) to the Authority. The TCAE should justify the arrangements for management of the MTC and be capable of expanding for subsequent changes to type design, MSTC and major repairs.

Government organisations seeking to become a MTC holder are required to identify an individual (a senior Defence engineer) responsible for managing the in-house and contracted holder obligations. The individual shall comply with the following qualifications and experience requirements:

Qualifications:

1. Bachelor of Engineering degree in Mechanical, Mechatronics, Aerospace, Aeronautical, Electronics, Software or Electrical Engineering.

2. Qualifications must be Australian accredited or assessed to be equivalent to Australian qualification by Engineers Australia, the Australian Computer Society or the Australian Institute of Project Management.

Experience:

1. Chartered Professional Engineer (CPEng) in the Institute of Engineers Australia or an equivalent professional body recognised by the IEAust.

2. Ten years of Aviation experience. The experience must comprise of at least two years’ combined experience as staff of DASA or an organisation holding a Design Organisation Approval under EASA, CASA, EMAR or DASR 21 Section A Subpart J.

The TCAE should contain the following:

Information regarding the eligibility of the organisation to hold the Type Certificate (and subsequent changes to type design, MSTC and major repairs) in accordance with the requirements of DASR 21.A.14 (and / or DASR 21.A.92(a) and / or DASR 21.A.112B and / or DASR 21.A.117(c) and / or DASR 21.A.432B if applicable). This includes demonstration against the recognition framework criteria (see below) where external design organisations have been engaged via DASR 21.A.2 to provide DASR 21 Subpart J, or holder functions.

An overview of the Product’s Type Design and Certification including subsequent modifications (and / or Supplementary Certificates and major repairs if applicable). Access arrangements to type design data for the life of type should be included here.

ADF Configuration, Role and Environment (CRE) (including a link to the SOIU).

ADF Capabilities to support the Product including specialist support.

Key organisations involved in the management of the product’s design, including their contractual relationships with Defence; their maturity, experience, capabilities, limitations, responsiveness, quality of product, impartiality, past performance, and future viability; and any gaps in overall coverage. Information related to DASR 21 subpart J approval held by the organisation or equivalent approvals held under recognised authorities should be included.

An assessment of the likelihood of leveraging other military and civil operator’s programs to support the Defence product’s design, including Defence’s ability to influence those programs, and the type of data that will be accessible.

Information related to the performance of holder obligations under DASR 21.A.44 (and / or DASR 21.A.118A and / or DASR 21.A.451 if applicable), including systems, processes and procedures used.

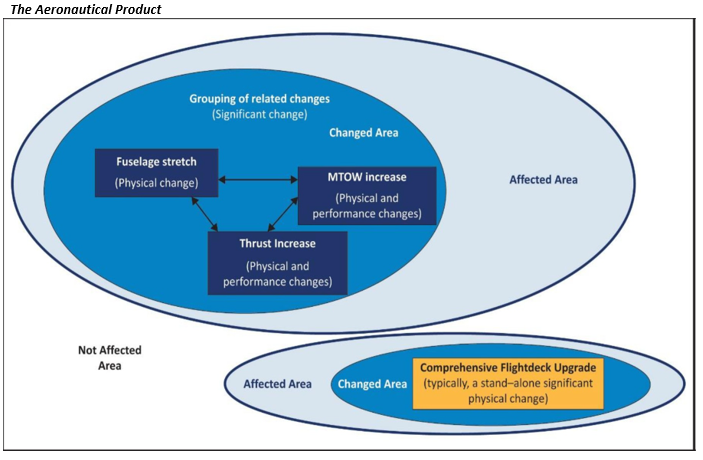

Information related to how the organisation, or the design organisation(s) with which they have an agreement, will perform its function as an applicant for and holder of any subsequent major changes to type design after the issue of the MTC. This information should include a methodology for major or minor classification of recognised design certifications.

Information related to how the requirements of DASR 21.A.42 for integration of Products, Weapons and other Systems onto the aircraft will be conducted.

Information about the nominated individual responsible for managing the in-house and contracted holder obligations and QTE compliance information.

System of managing changes to the TCAE including frequency of review and notifying the Authority of any changes.

How the organisation conducts internal governance including over their supporting design organisation(s)/network.

A compliance matrix describing how the organisation shall comply with each DASR applicable to fulfil the MTC Holder obligations.

Information related to how the requirements of DASR 21.A.3A for reporting failures, malfunction, defects and the rectification of unsafe conditions to the type design will be conducted.

Project Office demonstration of capability

Government organisations, (e.g. an Acquisition Project Office (PO)) seeking to apply for MTC / MRTC or MSTC also attain eligibility via DASR 21.A.14(c). PO's should engage DASA to obtain DASA acceptance on the arrangements for:

establishing procedures for a Design Assurance System that:

complies with the requirements of DASR 21 Subpart J, or

where the PO expects to exclusively base their application upon an aircraft type-design that has been certified by a recognised CAA / MAA, is sufficient to conduct the required certification programme activities (includes developing the Defence TCB and CPP, conduct applicability assessment against Defence CRE and context, and provide a declaration of compliance).

when engaging an external design organisation, include demonstration against the recognition criteria as described below.

The agreed arrangements should be formalised within relevant project or acquisition documents (such as the Acquisition Airworthiness Management Plan).

DASA recognition of other CAA / MAA

Where possible the engaged design organisation(s) should be approved under DASR 21 Subpart J (Military Design Organisation Approval). If the government organisation engages an external design organisation the DASA recognition framework should be used to support the eligibility assessment. Certificates for each recognised authority are available through the DASA website.

Requirements applicable to all applicants are:

the external design organisation (DO) is an approved design organisation within a recognised CAA / MAA or develops designs for certification by a recognised CAA / MAA,

the DO has appropriate technical scope and expertise for the ADF design,

the DO’s systems, processes and personnel used in developing other designs for certification by the parent CAA / MAA will be used in the design development or holder activities associated with the ADF design,

the DO will provide an attestation of compliance against the Type Certification Basis for any provided design product,

any oversight by the DO’s parent CAA / MAA is appropriate, and

where applicable, arrangements for DASA oversight are in place.

The government organisation should monitor the external DO to ensure continued adherence to requirements during the design development activities or provision of holder duties.

AMC 21.A.14(c) - Alternative Demonstration

In specific cases, governmental organisations might be required to act as the holder of military type-certificates or restricted type-certificates. Often, these entities do not meet the qualification requirement of 21.A.14(a) by own means. In such cases, 21.A.2 is usually considered being sufficient to discharge actions and obligations to another person or organisation. However, some legal arrangements still require the accountability to remain with the government owned entity, in which case the qualification requirement of 21.A.14(a) can only be met jointly. In such cases, the agreement required by 21.A.2 should also provide sufficient detail on the processes and procedures governing the cooperation, including allocation of tasks, rights, obligations, and privileges among the entities involved.

To undertake actions and obligations on behalf of the holder of a military certificate, the contracted organisation shall

ensure the necessary access to the data related to the type design

establish sufficient cooperation with the Authority to ensure oversight

In the case that alternative procedures (refer to DASR 21.A.14(b)) for establishing a Design Assurance System are used, such procedures shall be acceptable to the Authority in fulfilling the obligations required under DASR 21.A.44 - Obligations of the Holder.

By way of exception from paragraphs (a), (b) and (c), any organisation applying for a type-certificate or restricted type-certificate may demonstrate its capability by holding a military type-certificate holder organisation (MTCHO) approval, issued by the Authority in accordance with DASR 21 Subpart C.

21.A.15 - Application

An application for a type-certificate or restricted type-certificate shall be made in a form and manner established by the Authority.AMCAMC

AMC 21.A.15(a) ‐ Form and manner (AUS)

The application referenced in DASR 21.A.15 refers to the initial formal notification to the Authority of the intent to seek an MTC or MRTC. This can be achieved through notifying the Authority in writing of the intent, otherwise the submission of the first version of the certification programme will be taken as the initial application.

Final application for a type‐certificate or restricted type‐certificate is to be provided in writing to the Authority and shall address the requirements of DASR 21.A.21.

An application for a type‐certificate or restricted type‐certificate shall include, as a minimum, preliminary descriptive data of the product, the intended use of the product and the kind of operations for which certification is requested. In addition, it shall include, or be supplemented after the initial application, a certification programme for the demonstration of compliance in accordance with DASR 21.A.20, consisting of: AMCAMC GMGM GM1GM1

GM1 to 21.A.15(b) ‐ Certification Programme (AUS)

The certification programme for issue of an MTC / MRTC provided to the Authority by the applicant may take a variety of forms depending on the acquisition arrangements:

if the applicant is an MDOA holder, then the MDOA holder will develop and submit the certification programme;

if the applicant is a Defence Project Office and the prime design / integration organisation is an MDOA holder, or recognised equivalent, then the certification programme will be developed by the prime designer / integrator and provided to the Authority through the Defence Project Office;

if the Defence Project Office is the integrator of multiple design elements, then the Defence Project Office develops and submits the certification programme as the Applicant; or

if design organisation/s do not hold an MDOA or recognised equivalent, or have not been contracted to develop a certification programme, then the Defence Project Office will be required to develop and submit the certification programme as the Applicant.

For software certification aspects, the Authority encourages applicants to develop a Plan for Software Aspects of Certification (PSAC), or equivalent document, and provide it as an enclosure to the certification programme.

GM 21.A.15(b) ‐ Operating Characteristics and Intended Use of the Product (AUS)

The requirements of 21.A.15(b)2 and (b)3 will normally be covered in the aircraft Statement of Operating Intent and Usage (SOIU). Where the requirements of 21.A.15(b)2 and b(3) have been addressed, to the level of detail specified in AMC 21.A.15(b), through an SOIU which has received endorsement from the Authority, the certification programme can include reference to the SOIU without need for duplication of that information. Any detail not sufficiently covered in an endorsed SOIU will need to be provided in the certification programme.

AMC 21.A.15(b) ‐ Content of the certification programme

The certification programme is a document that allows the applicant and the Authority to manage and control the evolving product type design or Operational Suitability Data, as well as the process of compliance demonstration by the applicant and its verification by the Authority when required.

The certification programme may be based on modules that may be updated independently.

The level of detail in the certification programme depends on the complexity of the product and its intended use.

In particular, the following information should typically be expected:

General

Identification of the key organisations (e.g. Acquisition Project Office, prime design organisation) and of the relevant personnel who make decisions affecting airworthiness, operational suitability and environmental protection, and who will interface with the Authority, unless otherwise identified to the Authority (e.g. within the MDOA procedures).

Identification of any prior certification intended to be leveraged, including details of which TCB elements will leverage prior certification, and how compliance will be demonstrated when prior certification can only be partially leveraged.

A project schedule including major milestones.

Subcontracting arrangements for design, operational suitability, environmental protection and/or production as well as military design organisation approval (MDOA) responsibility sharing.

DASR 21.A.15(b)(1) ‘a detailed description of the type design, including all the configurations to be certified’

An overview of the:

architecture, functions, systems;

dimensions, design weights, payloads, design speeds;

engines and power/thrust rating;

materials and technologies;

maximum passenger seating capacity, minimum flight and cabin/mission crew;

cabin configuration aspects;

options (e.g. weight variants, power/thrust rating variants, optional avionics equipment items, auxiliary power unit (APU) choices, brake options, tire options, floats, skids);

mission (role) configuration options (other than cabin configuration), including aircraft level provisions for external stores, pods, tanks, or other similar equipment options,

noise/emissions level; and

other items, if considered to be more appropriate, that address the specific aeronautical product.

DASR 21.A.15(b)(2) ‘proposed operating characteristics and limitations’

Operating speed limitations.

Service ceiling, maximum airfield elevation.

Cabin pressure.

Limit load factors.

Number of passengers, minimum crew, payload, range.

Weight and centre‐of‐gravity (CG) envelope and fuel loading.