7.1.1.1 While there is no internationally-accepted definition for Initial Airworthiness, common definitions for ‘initial’ (happening at the beginning) and ‘airworthiness’ (the fact of an aircraft being safe to fly) are helpful. After all, Initial Airworthiness does indeed focus extensively on whether a new aircraft is initially safe to fly - that is, whether it has been suitably designed and manufactured.

7.1.1.2 However, by convention, Initial Airworthiness also encompasses any design changes subsequently made to the new aircraft (including the certification of those changes) and the design of repairs. Furthermore, it includes the activities needed to ensure the design remains safe throughout its lifecycle, although this activity is often termed ‘continued’ airworthiness (not to be confused with ‘continuing’ airworthiness, per chapter 8).

7.1.1.3 This chapter presents an overview of the DASR approach to aircraft design, production and certification, which are the activities commonly associated with initial and continued airworthiness. The subsequent chapters will then explore several of these concepts in more detail.

7.1.1.4 Note this chapter is relevant only to Defence Registered aircraft; for non-Defence Registered aircraft, all initial and continued airworthiness functions are conducted per the requirements of the relevant Civil or military Aviation Authority (normally CASA).

7.1.2.1 From an Initial and Continued Airworthiness (INCA) perspective, an aircraft’s lifecycle might follow a progression something like this:

To start, an engineering organisation demonstrates its professional ability to produce an aircraft design (‘design organisation approval’).

Next, the organisation produces a new aircraft design, and an Aviation Authority certifies that the design is suitably safe (‘aircraft design and certification’).

Individual aircraft are then produced, and an Aviation Authority certifies each as conforming to the certified design (‘aircraft production and certification’).

Over the following decades of fleet operation, numerous Minor and Major design changes and repairs will be made to the aircraft (‘aircraft design changes and repairs’).

Occasionally, there may be a need for limited flying of a possibly unairworthy aircraft, either to demonstrate a new capability or to avoid grounding an important asset (‘permit to fly’).

Critically, throughout this complex lifecycyle, an engineering organisation will need to monitor for defects in the design, facilitate risk management of the design, and so on (‘type certificate holder’).

Finally, an Aviation Authority might occasionally mandate certain remediation actions in the interests of fleet safety (‘airworthiness directives’).

7.1.2.2 Each of these seven functions, and several others, is regulated under DASR Pt 21– Aircraft Design, Production and Certification. The remainder of this chapter provides a brief summary of these functions.

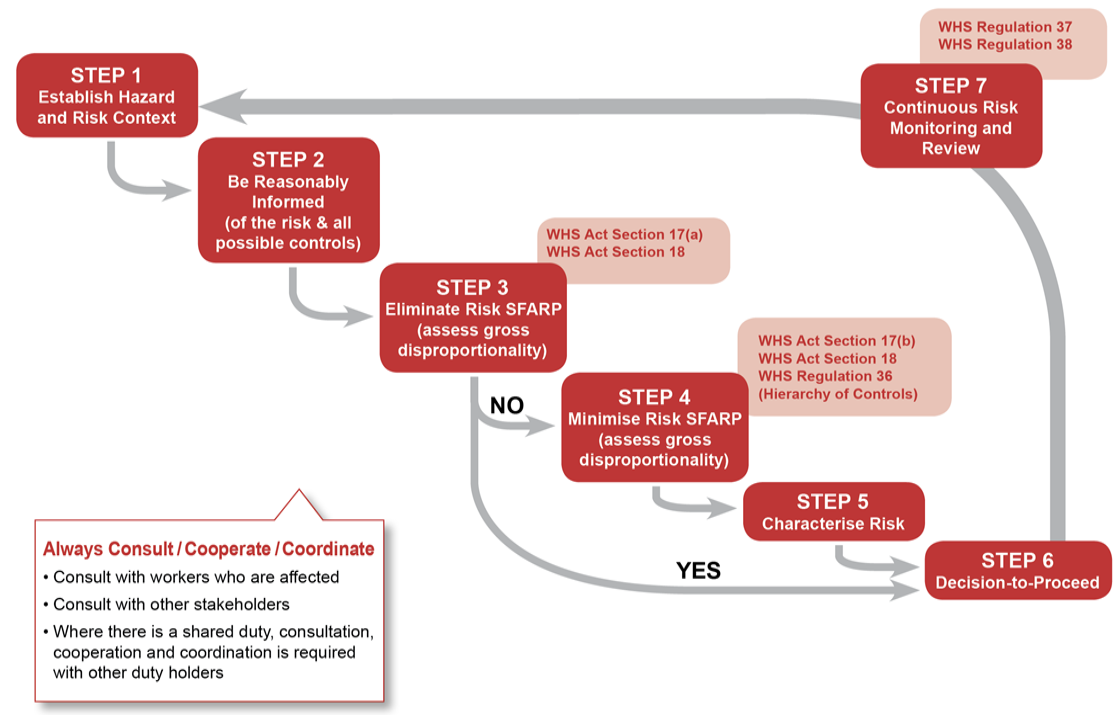

7.1.2.3 Design organisation approval. Deficiencies in an aircraft’s design can range from those with immediate catastrophic consequences (eg inadequate structural strength), to an erosion of safety margins (eg misleading navigation information), to an annoyance (eg a Minor human-machine interface flaw). Designing an aircraft where risks have been eliminated or otherwise minimised so far as is reasonably practicable (SFARP) is a particularly complex endeavour.

7.1.2.4 Consequently, the initial design of Defence aircraft should only be undertaken by skilled individuals within professional aircraft design organisations. DASRs make provision for DASA to issue Military Design Organisation Approval (MDOA) status to organisations who have demonstrated that they are able to maintain a design assurance system for the control and supervision of the design, and of design changes, of aircraft products, parts and appliances.

7.1.2.5 DASA’s default expectation is that a new Defence aircraft will be designed by a MDOA of suitable scope. As a matter of pragmatism, however, DASR also make provision for Defence to accept designs that have been certified by a DASA-recognised civil or military Aviation Authority (CAA/MAA), without the need for the design organisation to be a DASA-approved MDOA, within certain bounds. This approach, often called ‘prior acceptance’ is explored in Chapter 7.2, Product Certification. These same provisions apply for design changes to an extant aircraft.

7.1.2.6 MDOAs are explored in Chapter 7.6, Design and Production Organisations.

7.1.2.7 Initial aircraft design and certification. Defence periodically acquires aircraft to meet a capability need. In practice, Defence usually acquires its new aircraft as off-the-shelf designs, and then incorporates design changes to cater for Defence’s unique roles and operating environment. The entire design will meet a set of airworthiness requirements - commonly called a Type Certification Basis (TCB) - and the designer(s) will produce extensive evidence (via analysis, test and other means) to demonstrate that their design meets the TCB.

7.1.2.8 As noted in paragraph 7.1.2.5, these designs will be produced by a DASA-approved MDOA, or a design organisation whose design is certified by a DASA-recognised CAA/MAA, or sometimes both. Regardless, the final design will always be certified by DASA, signified by the issue of a Military Type Certificate (MTC)11 for the aircraft.

7.1.2.9 In the absence of a pertinent CAA/MAA certification, DASA’s certification for a new aircraft would be an immense undertaking for both DASA and the Defence acquisition organisation. More commonly, however, there will be a pertinent CAA/MAA certification, and leveraging off this certification can substantially reduce the impost on both organisations. In that case, much of the effort focuses on whether the certified design is compatible with Defence’s intended Configuration, Role and Environment (CRE). Chapter 7.2, Product Certification, explores the certification process in detail.

7.1.2.10 Aircraft production and certification. An expertly designed and certified aircraft provides the basis for safe aircraft operation. However, just as importantly, that design must be accurately implemented on the Defence aircraft.

7.1.2.11 DASR make provision for DASA to issue a Military Production Organisation Approval (MPOA) to an organisation when assured they have the ability to manufacture aircraft parts and appliances in conformity with approved data. DASR also make provision for Defence to accept an aircraft produced under the systems of a DASA-recognised CAA/MAA. This latter approach is used for most new Defence aircraft.

7.1.2.112 Following production of an individual aircraft, DASA must certify that the aircraft is in a state of airworthiness per the inherent level of safety specified on the MTC. This certification is signified by the DASA issue of a Military Certificate of Airworthiness (MCoA)22 for each individual Defence aircraft.

7.1.2.13 Aircraft production and MCoAs are explored in Chapter 7.3, Production. MPOAs are explored in Chapter 7.6, Design and Production Organisations.

7.1.2.14 Aircraft design changes and repairs. Defence aircraft will usually be in service for several decades. During this time, numerous design changes will inevitably be implemented, either to enhance military capability or to address design or obsolescence problems. These design changes are classified under DASR as either Minor of Major, differentiated by the degree of airworthiness effect of the design change.

7.1.2.15 The DASR approach for Minor and Major design changes is very similar. They will both be performed by a DASA-approved MDOA or another design organisation whose design is certified by a recognised CAA/MAA, and both should preserve the level of airworthiness of the aircraft. For Major design changes, however, DASA will usually provide a proportionate level of independent assurance, and DASA itself will usually certify the design as safe. This certification is usually via an amendment to the MTC, although occasionally a Military Supplemental Type Certificate (MSTC) may be issued. Chapter 7.2, Product Certification, explores the certification process in detail.

7.1.2.16 Throughout an aircraft’s life, degradation (damage) of the systems/structures integrity supporting safe flight may be compromised through direct (accidental impact and battle damage) overload, or insidious (fatigue, corrosion, moisture ingress, dis-bond, ultraviolet light etc) environmental sources. Repairs are those actions developed and implemented to restore damaged products to a suitably airworthy state. Similar to aircraft design changes, aircraft repairs are classified under DASR as Minor or Major, must be designed by a MDOA or other organisation agreed by DASA, and may be subjected to a proportionate level of DASA independent assurance.

7.1.2.17 Permit to fly. A Military Permit to Fly (MPTF) may be issued by DASA for an aircraft that does not meet, or has not been shown to meet, the requirements of its TCB, but is nonetheless capable of safe flight under defined conditions and for specified purposes. MPTFs are most commonly used for flight test (for aircraft development or role expansion activities), for flights where the design has not yet been certified, or for flights where the aircraft temporarily does not conform to the Type Design (eg due to unrepaired damaged, overdue maintenance, etc).

7.1.2.18 An MPTF may or may not entail an elevated level of risk, and is always associated with a set of flight conditions that may be approved prior to, or in conjunction with, the MPTF application. Chapter 7.5, Flight Conditions and Military Permits to Fly, explores this in more detail.

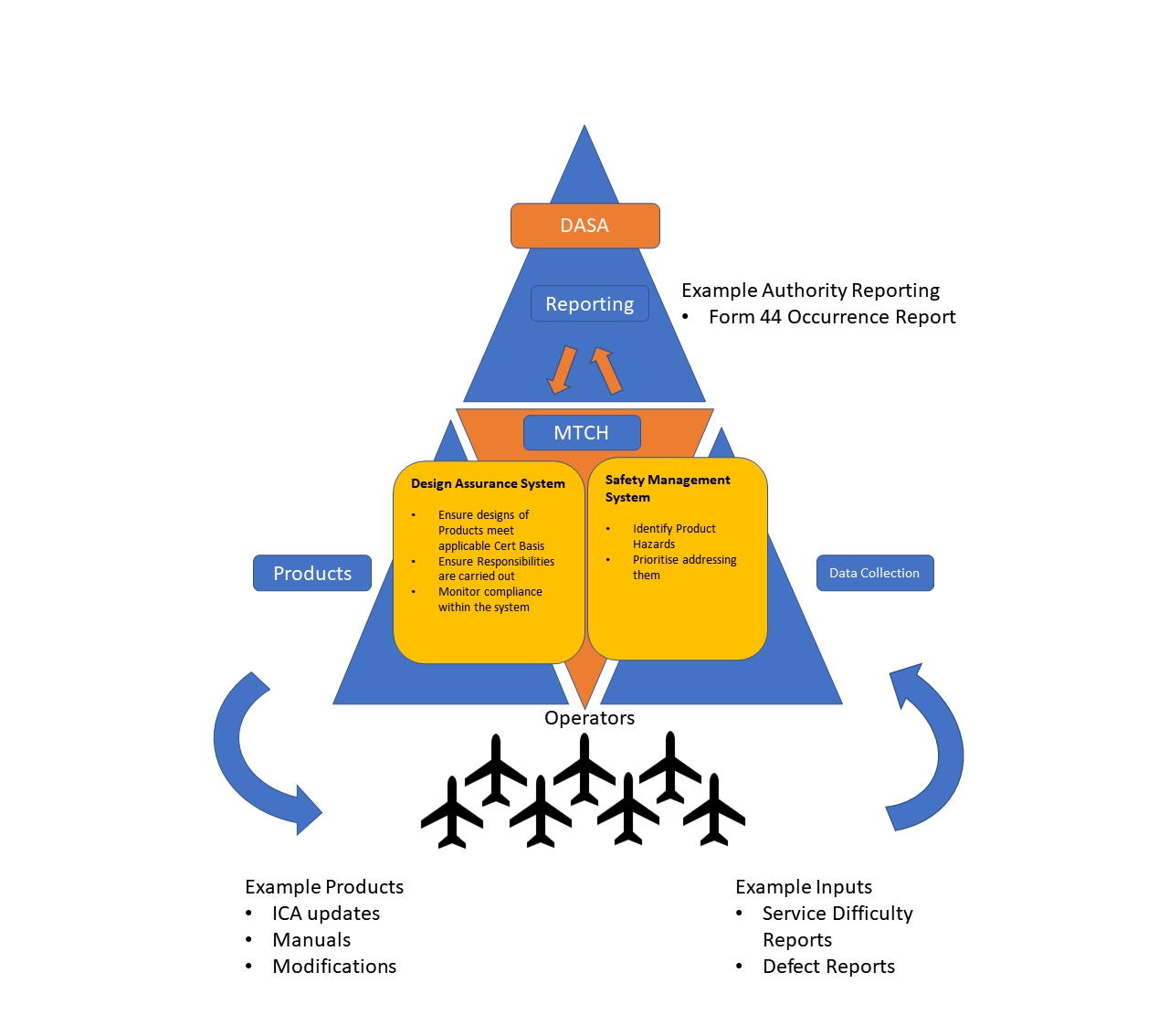

7.1.2.19 Type certificate holder. As noted earlier in this chapter, DASA issues an MTC for Defence Registered aircraft types. This MTC is issued to a suitable Commonwealth government organisation (usually the relevant Defence Systems Program Office), who are then charged with ‘holding’ the MTC.

7.1.2.20 Holding the type certificate involves undertaking certain obligations that ensure the type certificate is managed, and the level of safety inherent in the TCB is maintained. This includes, for a particular aircraft type, collecting aviation safety information (both locally and from external sources), ensuring operators are aware of extant hazards, ensuring that essential risk controls remain effective, leading local efforts to eliminate or further minimise known risks, and many other important roles.

7.1.2.21 These expansive holding responsibilities are often beyond the capacity and capability of the government organisation holding the MTC. Consequently, responsibility for the conduct of MTCH obligations is often vested with various support organisations, for example contractors, foreign project offices and other military operators. The government organisation remains accountable for all activities undertaken by those organisations.

7.1.2.22 Chapter 7.4, Continued Airworthiness, explores the MTCH role in more detail.

7.1.2.23 Airworthiness directives. In the Australian Defence context, the WHS Act and DASR place responsibility and obligation solely on the regulated community for managing the day-to-day safety of their aircraft, and for ensuring risks are eliminated or otherwise minimised so far as is reasonably practicable. DASR do, however, still make provision for DASA to mandate actions and/or impose conditions on aircraft operation in certain circumstances. This is achieved through the issue of an Airworthiness Directive (AD).

7.1.2.24 Like its civil counterpart, ADs under DASR provide a means to mandate an action in order to restore an aircraft to an acceptable level of safety, where that safety level may be otherwise compromised. However, due to Defence’s unique context, DASA issues ADs infrequently, particularly in comparison to civil aviation.

7.1.2.25 Chapter 7.4, Continued Airworthiness, explores DASR ADs in more detail.

7.1.2.26 Other. In addition to the seven common INCA functions mentioned above, DASR 21 also makes provision for a number of niche functions. Since this chapter aims to provide an overview of INCA that is consumable to a wide audience, these niche functions will not be explored here. They include: Australian Military Technical Standard Order (AUSMTSO) authorisations, restricted type certificates, restricted certificates of airworthiness, approval of parts and appliances, and the identification of parts and appliances.

Structure of these chapters

7.1.2.27 This chapter has provided a brief overview of the functions encompassed within Initial and Continued Airworthiness. The subsequent chapters explore several of these functions in greater detail, as follows:

Chapter 7.2: Product certification

Chapter 7.3: Production and military certificates of airworthiness

Chapter 7.4: Continued airworthiness (including military type certificate holders, occurrence reporting, airworthiness directives and other organisational approvals)

Chapter 7.5: Flight conditions and military permits to fly

Chapter 7.6: Design and production organisations.

7.2.1.1. Product certification authorisations represent DASA’s assurance that an individual product complies with the applicable airworthiness33 requirements. These are issued following review of compliance evidence presented by the applicant seeking product certification. Product certification authorisations covered under this chapter are MTCs, Changes to MTCs, MSTCs, and Repair Designs.

7.2.1.2. Product certification authorisations are built around four pillars of safety assurance; Organisational Capability, Compliance demonstration, Compliance Verification, and Obligations of the holder

7.2.1.3. Organisational Capability. Before an organisation can apply for a product certification, they need to be eligible. Eligibility is based on an assessment of whether the organisation is equipped/resourced to achieve a successful authorisation.

7.2.1.4. Compliance Demonstration. The applicant for a product certification authorisation must show that their product complies with the applicable airworthiness requirements.

7.2.1.5. Compliance Verification. The authority must independently verify that compliance has been achieved to the applicable airworthiness requirements. As compliance demonstration and compliance verification are intrinsically linked, a certification programme is put in place to document the means by which the applicant will demonstrate compliance and the authority will verify compliance.

7.2.1.6. Obligations of the Holder. Following issue of a certification approval, the certificate holder must continue to carry out obligations outlined under the DASRs to ensure the product certification remains safe.

7.2.1.7. The following sections expand upon these safety assurance areas for each product certification authorisation.

Overview

7.2.2.1 Scope of Section. Section 7.2.2 describes the DASR type certification process for obtaining a Military Type Certificate (MTC). Military Restricted Type Certificates (MRTCs) are not yet employed by DASA, and are not addressed herein.

7.2.2.2 Military Type Certificate. An MTC is issued by DASA to certify that a product’s type design complies with the applicable Type Certification Basis (TCB) when operated within specified conditions and limitations. Further description of the MTC authorisation can be found in Section 5.3 Annex K.

Eligibility

7.2.2.3 Applicant eligibility requirements exist to control how designs and applications are developed and presented to DASA for review and inspection. These ensure that DASA has visibility of the applicant’s organisation, understands and has confidence in the generation of compliance evidence and how the declaration of compliance is made, and has confidence in the applicant’s ability to fulfil the obligations associated with holding the MTC.

7.2.2.4 DASR 21.A.13 (Eligibility), and by extension DASR 21.A.14 (Demonstration of Capability), define which organisations can apply for an MTC under DASR 21. As per DASR 21.A.14, applicants for an MTC can be:

A DASR 21 Subpart J approved Military Design Organisation (MDO) (21.A.14(a)). Holding a DASR 21J approval provides an organisation with the eligibility to apply directly to DASA for an MTC. However, given the scope of the Australian aviation industry, development and certification of a new aircraft wholly under a DASR 21J MDO will be a rare occurrence.

An organisation demonstrating its capability through alternative procedures (21.A.14(b)). An applicant may seek DASA agreement for the use of procedures setting out the specific design practices, resources and sequence of activities necessary to comply with this DASR. This eligibility provision is ostensibly aimed at products with simple or limited scope of design, or organisations starting toward a MDO approval or limited duration of design activities. Use of this provision to demonstrate capability to apply for an MTC would only be considered by DASA by exception.

A government organisation who has an agreement in place with a design organisation that has access to the type design data (21.A.14(c)). Any government organisation applying for an MTC may demonstrate its capability by having an agreement in place, accepted by DASA, with a design organisation that has access to the necessary type design data. This is the normal provision through which DASA expects government organisations (usually the relevant CASG System Program Office (SPO)) to demonstrate their capability to apply for an MTC. The agreement with the relevant design organisation shall include detailed statements how the actions and obligations are delegated to enable the government organisation, in cooperation with the contracted organisation, to comply with the requirements of Subpart J and DASR 21.A.44 (holder obligations). AMC and GM to 21.A.14(c) provide further information on demonstration of capability under this provision.

7.2.2.5 MTC Applications by CASG SPOs (Project Offices). To be issued an MTC by DASA, a CASG project office develops a Type Continued-Airworthiness Exposition (TCAE) for DASA review. The TCAE details the CASG arrangements with the design organisation(s) that has access to the type-design data and through which the provision of holder obligation functions occur. Further guidance on holder obligations and arrangements can be found in Section 7.4.1.

7.2.2.6 CASG project offices seeking issue of an MTC are strongly encouraged to initiate early contact with DASA during the appropriate stage of the Capability Life Cycle (such as preceding, or early in, the Acquisition phase) to discuss how the DASR eligibility provisions will be met for the intended acquisition program.

7.2.2.7 The eligibility assessment will focus on the arrangement between CASG and supporting design organisation(s), and address how the arrangements comply with the requirements of DASR 21 Subpart J. Since a CASG project office scope of responsibility is usually limited to a single application, and does not include the through-life holder responsibilities, the CASG project office eligibility information is not required to be delivered as a single document and can instead be contained within Project or Acquisition documentation. The documentation requires review by DASA prior to the project office becoming eligible to act as an applicant. However, the CASG project office must include a transition plan to manage delivery of the Type Design to the MTC holder, and where the MTC holder organisation is being created, include plans for assessment of eligibility of the MTC holder, by DASA.

7.2.2.8 Additional guidance with respect to MTC applicant eligibility when CASG project offices wish to leverage recognition provisions is as follows:

Application will be exclusively based upon an aircraft type-design that has been certified by a recognised CAA/MAA. In this situation, the project office, in conjunction with any associated design organisation(s), can gain eligibility by demonstrating its ability to conduct the required certification programme activities (develop CPP, conduct applicability assessment against Defence context, develop the Defence TCB, and provide a declaration of compliance), rather than demonstrate full adherence to the DASR 21 Subpart J requirements.

Application will be based on a design that has not been certified, but was developed using a design system (organisation, people, processes, data, and tools) external to the DASR, and where that system is used to produce designs for certification by a recognised CAA/MAA. In this situation, the DASA recognition framework44 must be leveraged by the project office to assist in demonstrating to DASA that the arrangements with the external DO provides an acceptable equivalence to the DASR 21 Subpart J requirements. Activities to meet the eligibility requirements should be completed prior to initial engagement with DASA and throughout certification programme activities. The project office is to address the following expectations in their respective eligibility submission:

Confirm that the external design organisation is normally oversighted by a CAA/MAA recognised by DASA55.

Confirm that the external design organisation has appropriate technical scope and expertise for the intended design(s).

Confirm that the systems, processes and personnel used in developing other designs for certification by the parent CAA/MAA will be used in the design development or holder activities associated with the ADF design.

Confirm that the design organisation is able to provide an attestation of compliance against the Defence TCB for any provided design product.

Note: In some circumstances, the PO or MTC holder may wish to allow the external design organisation to engage directly with DASA for Defence TCB agreement, development and conduct of the CCP, and provision of a declaration of compliance to the Defence TCB. In this case, the eligibility documentation shall demonstrate that the external design organisation systems and process are sufficiently similar to the DASR 21J requirements to support such delegation.

Confirm any expected oversight by the DO’s parent CAA/MAA is appropriate.

Confirm where applicable, arrangements for DASA oversight are in place.

Articulate how the recognition arrangements as per paragraphs 7.2.2.8.(b)(iii), (iv) and (v) will be monitored and ensured during the design development and submission process66.

Certification Programme

7.2.2.9 Overview. Under DASR 21, a certification programme is required for all applications for an MTC, and the certification programme requires formal acceptance by DASA.

7.2.2.10 The certification programme provides the details necessary to understand the design activity and how certification will be achieved for that activity. A stand-alone document that presents the certification programme for formal DASA acceptance is termed a Certification Program Plan (CPP).

7.2.2.11 Two CPP templates are published on the DASA Website (one for MTCs and one for major changes/MSTCs), which provide detailed guidance on the structure and content of a certification programme. This section should be read in conjunction with the MTC CPP template.

7.2.2.12 The organisation(s) involved in the development and submission of a certification program for an MTC application will vary depending upon the acquisition arrangements. GM1 21.A.15(b) provides further guidance based on some common acquisition scenarios.

7.2.2.13 Contents of a Certification Programme. DASR 21.A.15(b) outlines the requirements for content of a certification programme for an MTC. Certification programmes must be tailored to meet the requirements of the certification activity.

7.2.2.14 The certification programme should be presented as a CPP containing the information required by DASR 21.A.15(b) and the supporting AMC. The MTC CPP template published by DASA will assist in meeting the required outcomes.

7.2.2.15 Two key outcomes are achieved through the development and DASA acceptance of the certification programme:

Applicant development and DASA agreement of the Defence TCB for the MTC77.

Formalising and agreement on the approach to be taken for demonstrating compliance against the Defence TCB, and the DASA Level of Involvement (LoI) in compliance demonstration activities.

7.2.2.16 Proposed Compliance Demonstration Items (CDIs). DASR 21.A.15(b)(5) requires that the CPP proposes a breakdown of the certification programme into meaningful groups of compliance demonstration activities and data, and a proposal for the means of compliance and related compliance documents.

7.2.2.17 A CDI is a meaningful group of compliance demonstration activities and data that can be considered, in isolation, for the purpose of performing the risk assessment that allows DASA to determine its LoI.

7.2.2.18 Applicants should follow AMC 21.A.15(b)(5) when proposing the CDIs, and the DASA MTC CPP template contains further guidance and tabular templates for presenting proposed CDIs.

7.2.2.19 Proposed DASA LoI. As outlined in AMC 21.A.15(b)(6), the Authority’s LoI is a list of activities and data, in which the Authority retains the verification of compliance demonstration (e.g. review and acceptance of compliance data, witnessing of tests, etc.), as well as the depth of the verification. The depth of the verification for individual compliance reports, data, test witnessing, etc., may range from spot checks to extensive reviews. DASA will respond to those retained compliance demonstration activities and data with corresponding comments or a ‘statement of no objection’. DASR 21.A.15(b)(6) requires that the CPP proposes the DASA LoI associated with compliance demonstration activities, noting that LoI should normally be proposed at the CDI level. As per DASR 21.A.15(b)(6), the DASA LoI must address the likelihood of an unidentified non‐compliance with the TCB requirements and the potential impact of that non‐compliance on safety (ie a risk-based determination). In practice, this is achieved through taking into consideration:

any novel or unusual features of the certification project, including operational, organisational and knowledge management aspects

the complexity of the design and/or demonstration of compliance

the criticality of the design or technology and the related safety risks, including those identified on similar designs

the performance and experience of the design organisation of the applicant in the domain concerned.

7.2.2.20 AMC 21.A.15(b)(6) contains a step-by-step process and extensive information that applicants should follow when determining the proposed DASA LoI. The DASA MTC CPP template also includes complementary guidance and tables. The three main steps that culminate in determining the DASA LoI are:

Step 1: Identification of the likelihood of an unidentified non-compliance. This includes taking into consideration novelty, complexity and the performance of the design organisation. Refer to Section 3.2 of AMC 21.A.15(b)(6) for details.

Step 2: Identification of the ‘risk class’. This includes determining whether the potential impact of the non-compliance within a compliance demonstration activity (ie CDI) is critical or non-critical. This is then combined with the likelihood of an unidentified non-compliance (step 1) to determine the risk class. Refer to Sections 3.3-3.4 of AMC 21.A.15(b)(6) for details.

Step 3: Determination of the DASA LoI. Based on the qualitative risk class identified for each compliance demonstration activity (ie CDI), the applicant should propose a DASA LoI. Refer to Section 3.5 of AMC 21.A.15(b)(6) for details.

7.2.2.21 DASA will determine the depth and extent of its inspections for each CDI, based on the information provided in the certification programme and the applicant’s proposal. DASA determination of LoI will be confirmed as part of DASA’s acceptance of the CPP. Note that the depth and extent of DASA LoI may change throughout the project in order to account for changes that affect the basis of the initial LoI determination.

7.2.2.22 Certification Programme Acceptance. DASA acceptance of the certification programme is required for all MTC applications. Early engagement with DASA, and agreement on the key certification programme content, will reduce schedule and resource risks for the project. Delaying presentation of certification programmes to DASA until after compliance demonstration has commenced may result in delays, additional work, or additional resources, due to DASA:

determining that the proposed airworthiness requirements or means of compliance are unsuitable for the certification activity

identifying a need for a LoI in compliance demonstration activities that have already been completed, therefore resulting in a need to repeat the compliance demonstration

identifying LoI that requires travel (eg for compliance demonstration being completed overseas) and insufficient time is available to organise funding and travel prior to the planned activity, resulting in a need to delay the activity

identifying a need for data access that was not accounted for prior to contracting or establishing government to government agreements for the activity, resulting in a need for contract changes or alternate workarounds.

7.2.2.23 DASA acceptance of a certification programme can be achieved incrementally, if some aspects are unknown at the beginning of the project or are expected to change throughout the project. A caveated acceptance may be possible to achieve agreement with DASA on specific aspects of the programme prior to full details being known. For an initial or caveated acceptance, the following is required:

identification of the applicant and any design organisations involved

broad detail on the design and aircraft intended use

an initial proposal for the TCB, including identification of the Primary Certification Code and identification of whether any TCB tailoring (including Military Certification Review Items (MCRIs)) will be required. Note: the TCB does not have to be fully defined at this point.

broad detail on the certification approach (i.e. whether there will be reliance on prior certification, or whether compliance demonstration evidence with be developed specifically for the DASA certification).

7.2.2.24 Where an incremental approach is taken to developing and achieving acceptance of the certification programme, the scope of acceptance intended by each version must be clearly understood and documented. A point at which the next update is required must be identified, this may be date based or linked to a specific project stage or milestone.

7.2.2.25 DASA acceptance of the certification programme will be agreed by formal communication, which will include confirmation of the DASA LoI for the activity, and any caveats on DASA acceptance.

7.2.2.26 Certification Programme Updates. In accordance with DASR 21.A.15(c), the certification programme is to be updated when there are changes to any of the content required under DASR 21.A.15(b). Key aspects that require the certification programme to be re-accepted by DASA are:

any changes that may impact on DASA LoI, such as:

change to the design or intended use

change to compliance demonstration approach (including the means of compliance)

change to the CRE Assessment (CREA) or its outcomes for a program that is leveraging prior certification

change to design organisation resources or approvals

any changes to the proposed TCB (except those achieving separate agreement via an MCRI)

significant changes to schedule that may impact on DASA LoI activities

7.2.2.27 Changes to the certification programme can be presented as an update to the original CPP, or via a supplement, depending on the scope of the changes.

7.2.2.28 Applicants should engage early with DASA (nominally DIA) staff and remain closely engaged with CPP development and subsequent amendment, heeding advice to prevent nugatory drafting and rewriting. The DASR Form 31 can be used to notify DASA of an upcoming certification project, to initiate discussions. A face-to-face session, before any CPP drafting occurs, is strongly recommended for for complex programs.

Type Certification Basis

7.2.2.29 Contents of a TCB. The TCB is an agreed set of airworthiness requirements that a product must be compliant with in order to obtain an MTC. The following DASR and concepts apply to the contents of a TCB:

DASR 21.A.16A (Airworthiness Codes). This regulation requires that DASA shall approve the use of Airworthiness Codes88 and other detailed specifications that may be used to demonstrate compliance of products, parts and appliances. As noted in GM 21.A.16A, rather than define a Defence-unique Airworthiness Code, DASA has elected to recognise the Airworthiness Codes prescribed by several other CAAs and MAAs that have been demonstrated to achieve safe flight, and then prescribe supplementation as required. The Defence Aviation Safety Design Requirements Manual (DASDRM) identifies the Airworthiness Codes recognised by DASA.

DASR 21.A.16B (Special Conditions). This regulation requires that DASA shall approve any special detailed technical specification (‘special conditions’) if the related Airworthiness Code or specifications do not contain adequate or appropriate safety standards. As per 21.A.16B, the need for special conditions may arise due to:

novel or unusual design features (relative to the design practices on which the applicable Airworthiness Code is based)

intended use of the product is unconventional

experience from other similar products in service or products having similar design features or newly identified hazards have shown that unsafe conditions may develop

applicable airworthiness codes do not exist for the concerned product class or do not address the requested kind of operations.

In the Defence context, special conditions are required when the primary Airworthiness Code selected may contain deficiencies against contemporary airworthiness requirements and / or may not account for Defence’s unique CRE. DASA uses the Defence Aviation Safety Design Requirements Manual (DASDRM) to define those 'essential' design requirements and standards that must be applied as special conditions to supplement Airworthiness Codes due to deficiencies in the Codes or to account for the Defence CRE. The DASDRM also defines a number of ‘recommended’ design requirements and standards for which compliance is not prescribed, but which should be applied where reasonably practicable.

DASR 21.A.17A (Type Certification Basis). This regulation defines the scope of the Defence TCB. The airworthiness requirements specified in the TCB include:

the applicable requirements from the DASA recognised Airworthiness Code selected as a basis for the Defence aircraft certification (the Primary Certification Code (PCC))

the applicable ‘essential’ requirements prescribed in the Defence Aviation Safety Design Requirements Manual (DASDRM)

any supplementation or tailoring agreed to by DASA.

7.2.2.30 Development of a Defence TCB. Development of a Defence TCB is a joint activity between the applicant and DASA and is guided by the DASR listed above and the Defence Aviation Safety Design Requirements Manual (DASDRM). TCB agreement is obtained through acceptance of the certification programme in accordance with DASR 21.A.15(b).

7.2.2.31 The TCB for a new Defence aircraft type should be developed and agreed as early as practicable in the aircraft acquisition life-cycle. While a DASA‐agreed TCB should be pursued prior to entering into an acquisition contract, this will not always be possible. In those cases, the acquisition project office may elect to present a draft TCB for DASA assessment as a cost and schedule risk reduction measure.

7.2.2.32 In most cases, DASR and the DASDRM allow the Defence TCB to be based on the recognised design standards used by the parent CAA/MAA under which the aircraft was initially designed and certified.

7.2.2.33 The TCB for a Defence aircraft must be consistent with Defence’s intended role and operating environment for the aircraft. In the aircraft Type Certification domain, CRE is a pivotal concept. Where an ab-initio Type Certification programme is proposed for a Defence aircraft, defining the CRE is essential to ensure that the basis of certification is consistent with the intended Defence use of the aircraft.

7.2.2.34 Where the Defence Type Certification programme intends to leverage prior certification from a recognised CAA/MAA to any extent, a CRE Assessment (CREA) is required to confirm the applicability of that prior certification to the intended Defence use. Areas where the prior certification is not entirely applicable to the Defence CRE must be addressed through further compliance demonstration evidence, inclusion of additional requirements in the TCB, or tailoring of requirements for the TCB. Further guidance on leveraging prior certification is contained in Annex B to Section 7.2, and further guidance on the conduct of a CREA is contained in Annex C to Section 7.2.

7.2.2.35 Tailoring the PCC. During a certification program, there may be a need to tailor the PCC when seeking an MTC. This tailoring may be required to supplement the PCC for a specific technology area, to specify later amendments of requirements or to otherwise account for the Defence CRE.

7.2.2.36 Tailoring of the PCC may be required to address a range of situations, such as CRE differences, special conditions, new means of compliance or any other certification issues that require clarification or interpretation.

7.2.2.37 Tailoring of the PCC can be achieved by directly including additional requirements or standards in the Defence TCB, or through use of a Military Certification Review Item (MCRI).

7.2.2.38 Annex A to Section 7.2 provides further guidance on tailoring the PCC, including when an MCRI is required and the MCRI categories adopted and employed by DASA, when Operator agreement is required to support PCC tailoring and how that agreement should be achieved, and illustration of the process involved in obtaining DASA agreement for tailoring.

Compliance Demonstration

7.2.2.39 Overview. Compliance demonstration evidence comprises of reports, engineering tool outputs, drawings, specifications, calculations, analysis etc. and provides a record of the means by which compliance with the applicable TCB is demonstrated. The applicant shall demonstrate compliance with the type‐certification basis either:

through compliance demonstration evidence developed by a MDOA holder (or alternative as agreed by DASA); or

through appropriate evidence of prior certification provided by another CAA / MAA.

7.2.2.40 The agreed certification programme will include details of how compliance demonstration is being achieved for each project. Where difficulty arises in meeting the agreed certification programme activities or outcomes, engagement with DASA as early as practicable is recommended. This phase may identify issues in compliance demonstration evidence against the agreed Defence TCB that require equivalent safety finding arguments, processing of exceptions underpinned by an Airworthiness Issue Paper (AwIP) or equivalent, or introducing new interpretations or means of compliance. In these cases an MCRI, and an AwIP as required, should be raised and submitted by the applicant for DASA consideration.

7.2.2.41 Leveraging Prior Certification. Defence is rarely the prime customer for new aircraft, so most acquisitions will be based on an aircraft design that has or will be certified by another CAA/MAA. DASR 21.A.20 enables an applicant for an MTC to leverage prior certification from a recognised CAA/MAA99 to gain relief from developing compliance demonstration evidence.

7.2.2.42 The fundamental principle of leveraging prior certification is that any requisite Authority review of evidence; testing, or witnessing of testing; or inspections (refer DASR 21.A.33(b)) have already been performed by a competent Authority (ie a CAA/MAA recognised by DASA). Therefore, duplicate effort in terms of DASA also conducting inspections / analyses / tests is unnecessary. However, as per DASR AMC 21.A.20, in order to leverage the prior certification, the applicant for the MTC must ensure:

the certification is within the scope, conditions and caveats specific to DASA Recognition of the certifying CAA/MAA

the CAA/MAA is sufficiently experienced in certification of the particular design activity

the certification requirements employed by the CAA/MAA are understood and any deltas from the Defence TCB have been addressed

the CRE applied to the prior certification is understood and any deltas from the intended Defence CRE have been addressed

any safety risks associated with the CAA / MAA certification have been identified, and have been eliminated or otherwise minimised So Far As is Reasonably Practicable (SFARP) for the Defence CRE.

7.2.2.43 Annex B to Section 7.2 provides additional guidance on the AMC 21.A.20 requirements for leveraging prior certification, and discusses common issues encountered with leveraging prior certification. Annex C to Section 7.2 provides further guidance on the conduct of a CREA to support relief from presenting CDE when leveraging prior recognition.

7.2.2.44 Structures and Propulsion System Specific Guidance. Guidance on the conduct of structures and propulsion system CREAs when leveraging prior certification can be found in GM1 21.A.20 and Chapter 6.6.2. Guidance to support AMC 21.A.41 (Structural and Propulsion System Critical Parts and Airworthiness Limitations (AUS)) can be found in Chapter 6.6.2.

MTC Application, Issuance and Type Certificate Data Sheet (TCDS)

7.2.2.45 Application. Upon completion of all activities identified within the CPP, including development of compliance demonstration evidence and completion of DASA LoI, the applicant provides the required declaration of compliance (refer DASR 21.A.20(d)) and formally applies to DASA for issuance of an MTC. The exact format of the application for an MTC will differ depending upon each project, and should be agreed within the CPP.

7.2.2.46 Issuance. Upon receipt of the application, DASA assures itself that agreed certification programme activities have been completed, and will issue the MTC.

7.2.2.47 For acquisitions of new aircraft types, the Defence Aviation Authority (Defence AA) will generally elect to convene an Airworthiness Board (AwB). Aircraft acquisition AwBs, including applicant and DASA submission of documents to support the AwB, are separate to the DASR type certification process outlined within this section. AwBs are discussed further in Section 6.1.2 and Section 13.

7.2.2.48 Type Certificate Data Sheet (TCDS). A TCDS will accompany each MTC. The TCDS contains all information (or reference thereto) about the type certification of the product including the TCB, the type design, operating limitations, the Aircraft Flight Manual (AFM), Instructions for Continuing Airworthiness (ICA), Airworthiness Limitations (AwLs), Certification Maintenance Requirements (CMRs), critical parts list (if applicable) and any other data necessary for the continued safe operation of the product.

7.2.2.49 DASA will develop and issue the TCDS concurrently with the MTC.

DASA Assurance

7.2.2.50 DASA independent safety assurance activities occur throughout the type certification process, and will vary in nature, scope and depth based on each individual project. Key DASA assurance activities for obtaining an MTC include:

DASA acceptance of the certification programme (refer ‘Certification Programme’ section above).

DASA agreement of the TCB, including tailoring (refer ‘Type Certification Basis’ section above).

DASA LoI in compliance demonstration activities. The term LoI describes DASA’s involvement in the verification of compliance demonstration. DASA LoI can include review of compliance data and information; testing, or witnessing of compliance testing; or inspections (refer DASR 21.A.33(b)). Depending upon the design, DASA LoI may occur over an extended duration and include on-site witness activities. DASA LoI will have been defined in the certification program (refer ‘Certification Programme’ section above). In all cases, DASA LoI activities should be successfully completed prior to the applicant’s declaration of compliance.

DASA assurance activities related to leveraging prior certification. These activities can be broadly described as DASA review of the evidence and artefacts that support the applicant’s claims that prior CAA/MAA certification can be leveraged (refer below for more detailed information).

DASA assurance activities related to the final application. These activities typically include review / evaluation of compliance artefacts submitted as part of the final application, and issue of the MTC and TCDS.

7.2.2.51 DASA Assurance when Leveraging Prior Certification. Where the certification programme indicates that an applicant is proposing to leverage prior certification from a recognised CAA/MAA, then DASA assurance activities will focus on the criteria outlined in AMC 21.A.20. The guidance outlined in Annex B to Section 7.2 provides an indication of the considerations that DASA will examine as part its assurance activities.

7.2.2.52 For certain aspects, the CPP will only be providing a proposal for how the applicant intends to address the criteria for leveraging prior certification outlined in AMC 21.A.20. For example, the applicant may need to conduct further activities to confirm that the CAA/MAA is sufficiently experienced in certification of the particular design activity, conduct further analysis to show that the design is compliant for the Defence CRE, and conduct sovereign assessments for safety risk decisions or risk retention made by an MAA. Therefore, DASA will typically request the applicant provide relevant documentation prior to, or as part of, the final application.

7.2.2.53 Note that while leveraging prior certification may provide relief from the need to develop new compliance demonstration evidence, it does not provide relief from the need to present compliance demonstration evidence to DASA. As such, DASA may request to review evidence that supported the prior certification where it is deemed necessary. Where it is not possible for the applicant to provide this evidence to DASA, for example due to limitations on access to OEM data, this will be negotiated between the applicant and DASA on a case-by-case basis.

MTC Holder Obligations

7.2.2.54 MTC holder obligations are outlined in DASR 21.A.44. Refer to Section 7.4.1 for detailed guidance on MTC holder obligations.

Overview

7.2.3.1 Scope of Section. Section 7.2.3 primarily describes the DASR type certification process for major changes to the type certificate and obtaining a Military Supplemental Type Certificates (MSTC). Minor changes to the type certificate are only briefly addressed herein.

7.2.3.2 Change to a Type Certificate. As defined by DASR 21.A.41, the type certificate includes:

The Type Design, which includes1010:

The drawings and specifications, and a listing of those drawings and specifications, necessary to define the configuration and the design features of the product shown to comply with the applicable TCB;

Information on materials and processes and on methods of manufacture and assembly of the product necessary to ensure the conformity of the product;

An approved Airworthiness Limitations Section (ALS) of the ICA as defined by the applicable airworthiness codes; and

Any other data allowing by comparison the determination of the airworthiness of later products of the same type.

Operating Limitations

The TCDS

The applicable TCB

Any other conditions or limitations prescribed for the product in the applicable airworthiness requirements.

7.2.3.3 A change to any aspect of the items listed above is considered a change to the type certificate, and must be undertaken in accordance with DASR 21 Subpart D or E.

7.2.3.4 Note that DASR M.A.304(d) allows for the Operator to directly consume data for minor changes that has been approved within the framework of Authorities recognised by DASA. Under this pathway, the requirements of DASR 21 are not applicable. Direct consumption of data is subject to a suitability assessment (see AMC and GM to DASR M.A.304(d)) in accordance with the scope, conditions and caveats of the relevant recognition certificate. Data for major changes cannot be directly consumed via recognition, and must be processed in accordance with DASR 21 Subpart D or E. Refer to Section 8.2 for further information on the direct consumption of data via recognition. Consumption of data for minor changes via recognition is not discussed any further within this section.

Classification

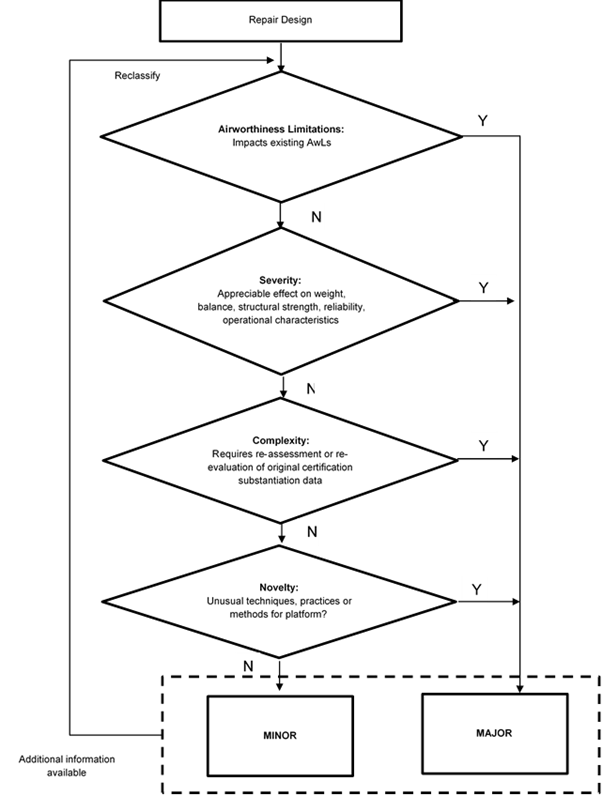

7.2.3.5 In accordance with DASR 21.A.91, all changes to the type certificate must be classified as minor or major.

7.2.3.6 A minor change is defined as a change that has no appreciable effect on the mass, balance, structural strength, reliability, operational characteristics, or other characteristics affecting the airworthiness of the product. All other changes are defined as major. Guidance on classification of changes to type certificates, including examples of changes that should be classified as major, can be found in DASR GM 21.A.91.

7.2.3.7 DASR 21J MDO approval holders will typically have the privilege to classify changes that are within the scope (e.g. technology or platform types) of their terms of approval. As noted in DASR GM 21.A.91, DASA should be consulted for clarification wherever there is doubt as to the classification of a change. Furthermore, when the strict application of the DASR GM 21.A.91 paragraph 3.4 criteria results in a major classification, the applicant may request reclassification, if justified, and DASA can take the responsibility in reclassifying the change.

Processing of Minor Changes

7.2.3.8 Minor changes to the type certificate must be undertaken in accordance with DASR 21 Subpart D, and can be approved by DASA or a DASR 21J MDO approval holder with the necessary privilege and scope. DASA expects that in the Defence context, minor changes to type certificates undertaken in accordance with DASR 21 Subpart D will be developed and approved by a DASR 21J MDO1111.

Processing of Major Changes

7.2.3.9 Changes that are classified as major can be processed and approved as a:

major change to the existing MTC under DASR 21 Subpart D, or

a MSTC under DASR 21 Subpart E.

7.2.3.10 The decision to apply for a major change (DASR 21 Subpart D) versus a MSTC (DASR 21 Subpart E) will depend upon the specific context. Under the DASR construct, both these authorisations will be issued to the government MTC holder. The default approach is usually issue a major change to the existing MTC, however, as discussed in the following sub-section, there may be cases where an MSTC is more appropriate.

Use of Military Supplemental Type Certificates (MSTCs)

7.2.3.11 The reasons for using an MSTC are different in the Defence context from in the civilian context. This sub-section provides guidance on when an MSTC should be used under the DASR.

7.2.3.12 Civil use of Supplemental Type Certificates (STCs). In the civil context, STCs are generally used for commercial purposes. They are used where a designer (either the OEM or another designer) alters the aircraft to provide a new capability that they can sell separately to the original Type Certificate. Of note, designers who are not the holder of the original Type Certificate can only ever apply for STCs for design changes that are classified as major, as it is not possible to apply for a major change to a certificate you do not hold.

7.2.3.13 Major changes to the Type Certificate are limited to changes done by the Type Certificate Holder, and are mostly (though not always) mandatory Service Bulletins and Airworthiness Directives to address safety issues identified in service as part of the holder obligations (eg DASR 21.A.3A).

7.2.3.14 Use of MSTCs Under DASR. Under the DASR the reasons for using an MSTC are different to the civil context. The following are the reasons that an MSTC (as opposed to a major change to the MTC) would be used under the DASR:

Sub-fleet: An MSTC may be used to manage a sub-fleet. This would be where there is one or more aircraft in the fleet that are intended to be configured or operated in a significantly different manner to the remainder of the fleet. Note, sub-fleets can also be managed via major changes to the MTC, so an MSTC may be used but is not the only option for management of sub-fleets.

Significant Change to the TCB: An MSTC may be used to manage a change that involves a distinct change to the TCB. Generally this will be the result of reliance on prior certification which has adopted a different PCC than that used for the original MTC. While the change to the PCC may be able to be managed via MCRI(s), it may reduce the complexity of ongoing management of the authorisations by covering the change under an MSTC.

Large and Complex Changes: An MSTC may be used for large and complex changes. While the process for review and approval of a major change or an MSTC is the same, use of an MSTC provides greater visibility, and as a result greater clarity, of the precise nature and scope of the change. MSTCs are often understood by Defence Operators as being a change of more significance, which warrants greater operational consideration.

Management Reasons: An MSTC may be used for ease of management from the perspective of the MTC holder. This may be required to provide alignment between the DASR authorisations and authorisations being leveraged via recognition. It may be simpler for an MTC holder to manage their obligations if the Defence authorisations are aligned with the OEM authorisations.

7.2.3.15 Note that when changes are applied to the MTC for a platform that also has MSTC(s), the compatibility of the change with the existing MSTC(s) must be explicitly addressed. Under the civil system, a change to the Type Certificate does not need to explicitly consider compatibility with potential STCs. It is the Operator’s responsibility to consider the impact of change to the Type Certificate against any STCs applied to their aircraft, and to engage the STC holder as required. However, in the DASR context, the MTC and MSTCs are frequently more integrated and less able to be clearly separated from each other. In addition, the MTC and MSTCs are all held by the same organisation so separating consideration of the MTC and MSTCs is unnecessary and adds confusion for no benefit. As such, it is not appropriate to progress a major change to the MTC without considering the impact on existing MSTCs.

Eligibility

7.2.3.16 Applicant eligibility requirements exist to control how designs and applications are developed and presented to DASA for review and inspection. These ensure that DASA has visibility of the applicant’s organisation, understands and has confidence in the generation of compliance evidence and how the declaration of compliance is made, and has confidence in the applicant’s ability to fulfil the obligations associated with holding the relevant authorisation.

7.2.3.17 Major Change to the MTC. In accordance with DASR 21.A.92, only the MTC holder can apply for a major change to the MTC. However, as noted by DASR GM 21.A.92(a), this includes any organisation acting on behalf of the MTC holder. DASA considers it appropriate for a design organisation to act as the applicant for a major change (on behalf of the MTC holder) where:

the agreement between the MTC holder and design organisation required by DASR 21.A.14(c) permits,

the TCAE reflects the agreement and arrangements under which such applications may occur, and

the proposed design change is within the scope of the design organisation’s approval.

7.2.3.18 In all cases, the MTC holder must sign the final application for the major change (ie Form 31A) to confirm that they have been consulted on, and have no objection to, the major change, and will carry out holder responsibilities.

7.2.3.19 During sustainment, additional design organisations may be engaged by the MTC holder to support new modifications or reflect expanding design support agreements. In these cases, the MTC holder should inform DASA of the proposed support arrangements and define additional oversight requirements to support specific applications.

7.2.3.20 MSTC. In accordance with DASR 21.A.112A, any organisation that has demonstrated, or is in the process of demonstrating, its capability under DASR 21.A.112B shall be eligible as an applicant for an MSTC. The DASR 21.A.112B demonstration of capability requirements are essentially the same as those of DASR 21.A.14 (refer to the ‘Eligibility’ guidance in Section 7.2.2, and relevant AMC and GM for further information).

7.2.3.21 However, as noted by DASR GM 21.A.115, DASA will issue all MSTCs to the relevant government MTC holder organisation. This means that, in effect, all applications for MSTC are being made on behalf of the MTC holder who will be the eventual holder of the MSTC. Applicants for MSTCs must be able to demonstrate that they are acting on behalf of the MTC holder.

7.2.3.22 Major Change or MSTC Applications by CASG Project Offices. In some cases, the CASG project office may act as the applicant for a major change or MSTC for larger or more complex modifications to an existing aircraft, such as for a mid-life upgrade program or significant capability upgrades.

7.2.3.23 Since only the MTC holder can apply for major changes to the existing MTC, the CASG project office would be considered to be applying for the approval on behalf of the MTC holder. For MSTC applications, the CASG project office could be considered the applicant under the DASR 21.A.112B(c) exception clause. In either case, the eligibility assessment will focus on the arrangement between CASG and supporting design organisation(s), and address how the arrangements comply with the requirements of DASR 21 Subpart J.

7.2.3.24 Also refer to the ‘MTC Applications by CASG SPOs (Project Offices)’ guidance in Section 7.2.2 for further information, including guidance on applicant eligibility when CASG project offices wish to leverage recognition provisions.

7.2.3.25 CASG project offices seeking to apply for a major change or MSTC are strongly encouraged to initiate early contact with DASA during the appropriate stage of the Capability Life Cycle (such as preceding, or early in, the Acquisition phase) to discuss how the DASR eligibility provisions will be met for the intended program.

Certification Programme

7.2.3.26 Overview. Under DASR 21, a certification programme is required for all changes to type certificates and MSTCs. The certification programme provides the details necessary to understand the design activity and how certification will be achieved for that activity. A stand-alone document that presents the certification programme for formal DASA acceptance is termed a CPP.

7.2.3.27 For MSTC and ‘complex’1212 major change programs, the certification programme must be presented to DASA for formal acceptance prior to the final application and declaration of compliance, and it is recommended that it be presented as a CPP. For other certification activities, the certification programme may be documented through the design pack or final application, and does not require formal DASA acceptance. Table 7.1 summarises the certification programme requirements for different design activities.

|

Certification Activity |

DASR Reference |

Formal DASA Acceptance Required? |

Comments |

|

Application for an MSTC

|

Yes |

Certification programme should be presented as a CPP containing the information required by 21.A.93(b) and the supporting AMC. The DASA major change/MSTC CPP template will assist in meeting the required outcomes. |

|

|

Application for a ‘complex’ major change |

Yes |

||

|

Application for a ‘simple’ major change |

Yes |

Certification programme can be provided with the final application for approval of the change. |

|

|

Minor change to type-certificate |

No |

|

Table 1: Certification Programme Requirements for Design Change Activities

7.2.3.28 Two CPP templates are published on the DASA website (one for MTCs and one for major changes/MSTCs), which provide detailed guidance on the structure and content of a certification programme. This section should be read in conjunction with the major change/MSTC CPP template.

7.2.3.29 The organisation(s) involved in the development and submission of a certification program for a major change or an MSTC application will vary depending upon the platform support arrangements. As noted above, the design organisation that supports the MTC holder functions may act as the applicant on behalf of the MTC holder in certain circumstances. In these cases, the design organisation will usually develop the CPP and engage with DASA for formal acceptance when required.

7.2.3.30 Simple Major Changes. For ‘simple’1414 major changes, the certification programme may be presented with the final application (ie with the Form 31a pack). This approach introduces a risk that if DASA identifies issues with the certification programme, or with the decision to treat the change as simple, there may be a requirement for rework of compliance demonstration activities, resulting in a delay to the program. As such, this approach should only be followed where the change is straightforward; for example, OEM Service Bulletins that have received CAA/MAA certification. If there is doubt as to whether a change would meet the definition of ‘simple’, DASA Type Certification section should be contacted for advice.

7.2.3.31 Contents of a Certification Programme. DASR 21.A.93(b) outlines the requirements for content of a certification programme for a major change or an MSTC.

7.2.3.32 Certification programmes must be tailored to meet the requirements of the certification activity. If a change has been assessed as ‘simple’, then there is no need to do a full breakdown of the programme into CDIs or to provide a detailed LoI proposal, as the LoI must be assessed as nil to meet the definition of a simple change. For changes that rely on prior certification, the breakdown of the programme into CDIs is only required for areas that are not able to fully leverage prior certification (ie where additional compliance demonstration evidence is being developed).

7.2.3.33 For ‘complex’ major changes and MSTC, the certification programme should be presented as a CPP containing the information required by DASR 21.A.93(b) and the supporting AMC and GM. The major change/MSTC CPP template published by DASA will assist in meeting the required outcomes.

7.2.3.34 Further Guidance. Refer to the certification programme information in Section 7.2.2 for further guidance on proposal of CDIs and DASA LoI, as well as certification programme acceptance and updates.

Certification Basis

7.2.3.35 For all changes to a product, the design organisation must identify the areas affected by the change and the corresponding certification basis (airworthiness requirements) for those areas. The applicable airworthiness requirements will depend upon the nature of the change, and can be generalised as follows:

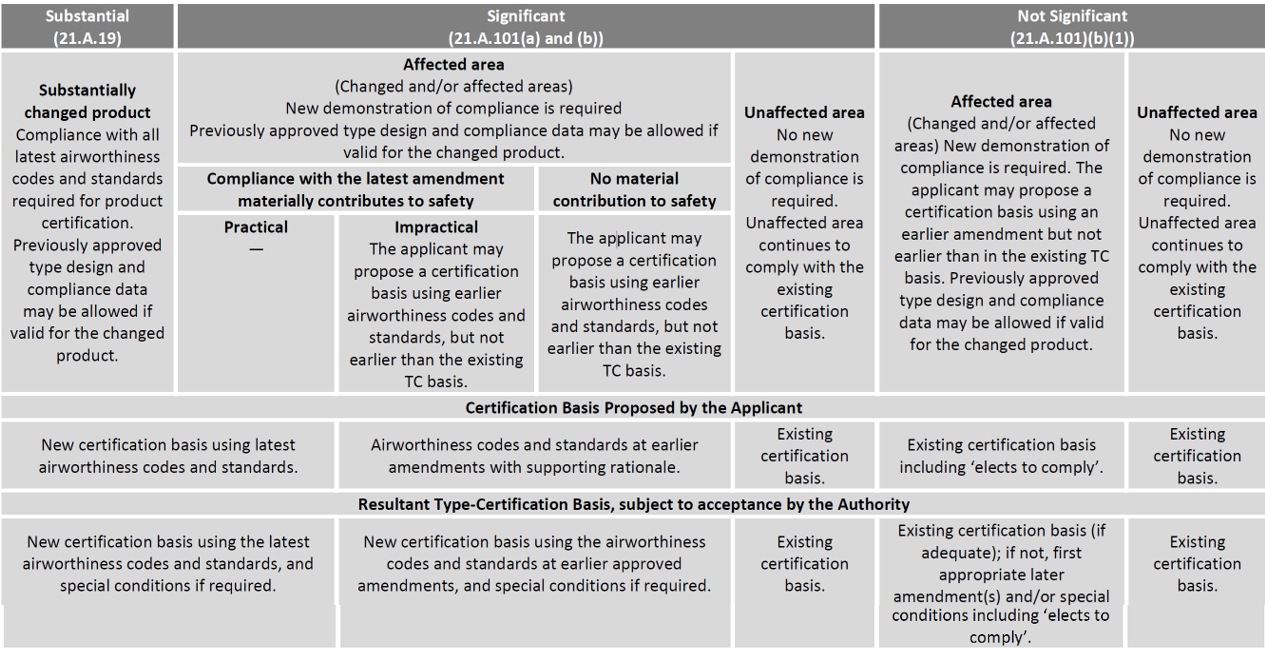

Substantial changes. Some changes are so extensive that a new type certificate is required (refer DASR 21.A.19), and therefore would require an entirely new TCB to be established. Substantial changes for an existing aircraft type are unlikely within the Defence context.

Significant (major) changes. For major changes that are categorised as significant1515 under DASR 21.A.101, then the latest amendment level of the airworthiness requirements referenced in the TCB should be used for the change.

Non-significant (major) changes. For major changes that are not categorised as significant, then the DASR 21.A.101(b) exception clause allows the existing airworthiness requirements in the TCB to be used for the change. DASR 21.A.101(b) also allows the existing airworthiness requirements to be used for a significant change in cases where use of the latest amendment of the airworthiness requirements referenced in the TCB would not contribute materially to the level of safety, or is impractical.

Minor changes. Minor changes, by definition, do not affect the airworthiness of the product. This means that it is appropriate to use the existing airworthiness requirements in the TCB for the change (refer DASR 21.A.95(b)(1) and DASR AMC 21.A.95).

7.2.3.36 As stated above, using the existing airworthiness requirements in the TCB is usually considered adequate for minor changes and non-significant major changes. However, as noted in DASR GM 21.A.93(b)(2), Australia’s WHS Act levies additional obligations on designers, namely to exercise ‘reasonable knowledge’ when determining that any risk inherent in designs has been minimised SFARP. Updates (later amendments) to applicable standards may provide insight into hazards and potential controls that are not identified in the existing TCB. The requirements prescribed in the DASDRM also provide a source of requirements and standards that can assist engineers to satisfy their obligation to exercise reasonable knowledge of hazards and associated controls in aircraft design.

7.2.3.37 The certification programme for the change should identify the proposed certification basis (ie existing or latest amendment level, with justification as required) and any ‘reinvestigations’ required1616.

7.2.3.38 Changed Product Rule. DASR 21.A.101 is commonly referred to as the ‘changed product rule’ and is used by applicants and DASA to establish the certification basis for major changes and MSTCs. The primary decision under the changed product rule is whether the latest amendment of the airworthiness requirements referenced in the TCB must be used (ie significant major change), or whether the nature of the major change allows the existing airworthiness requirements to be used (ie non-significant major change). If an applicant elects to comply with the latest amendment for a major change that could otherwise be categorised as non-significant, then the change will be compliant with DASR 21.A.101(a) and no further justification would be required.

7.2.3.39 DASR GM 21.A.101 contains extensive guidance and a step-by-step process for applicants to follow in order to establish the proposed certification basis for the major change. A summary of the changed product rule criteria and outcomes is shown below in Table 7.2. Table 7.2 is taken from Appendix B to GM 21.A.101, and only provides a brief summary of the extensive guidance and step-by-step process contained in DASR GM 21.A.101. A number of the Appendices to GM 21.A.101 refer to the EASA GM 21.A.101, including Appendix A of EASA GM 21.A.101 which provides examples of changes that EASA, the FAA and other Authorities considered to be ‘substantial’, ‘significant’ and ‘non-significant’.

Table 2: Establishing Certification Basis for Changed Products

7.2.3.40 Significant major changes shall also comply with the relevant ‘essential’ design requirements defined in the DASDRM (refer DASR AMC 21.A.101).

7.2.3.41 Note that for major changes, DASR 21.A.101(e) is a further exception clause that allows applicants to propose an alternative to the airworthiness requirements in the TCB. DASA may agree to the use of an alternative set of airworthiness requirements provided the alternative provides at least an equivalent level of safety to the existing TCB.

7.2.3.42 The process and justification used to comply with DASR 21.A.101 should be included within the certification programme, and the DASA major change/MSTC CPP template contains specific headings to include this information.

7.2.3.43 When applicants believe that the major change under consideration may be significant, or have questions about application of DASR 21.A.101, then engagement with DASA as early as practicable is recommended.

7.2.3.44 Tailoring the TCB. During a certification program, there may be a need to tailor the TCB when seeking a major change approval. This tailoring may be required to supplement the PCC for a specific technology area, to specify later amendments of requirements or to otherwise account for the Defence CRE.

7.2.3.45 Tailoring of the TCB may be required to address a range of situations, such as CRE differences, special conditions, new means of compliance or any other certification issues that require clarification or interpretation.

7.2.3.46 Tailoring of the TCB can be achieved by directly including additional requirements or standards in the Defence TCB, or through use of a MCRI.

7.2.3.47 Annex A to Section 7.2 provides further guidance on tailoring the TCB, including when an MCRI is required and the MCRI categories adopted and employed by DASA, when Operator agreement is required to support TCB tailoring and how that agreement should be achieved, and illustration of the process involved in obtaining DASA agreement for tailoring.

Reclassification of Changes Requiring TCB Tailoring

7.2.3.48 Occasionally, changes to type certificates that would otherwise be classified as minor, are required to be classified as major only because of the need to tailor the TCB. This section outlines an approach to enable these changes to be reclassified to minor, once the TCB tailoring has been agreed. This approach will allow greater use of DASR 21J MDO privileges, and reduce DASA assurance in areas where there is not a clear safety benefit.

7.2.3.49 Reclassification Justification. DASR GM 21.A.91 states that any changes that require an adjustment of the TCB, other than electing to comply with a later amendment of a requirement, must be classified as major. However, it also states that when the strict application of the classification criteria for a design change results in a major classification, the applicant may request re-classification, if justified, and DASA can take the responsibility in re-classifying the change.

7.2.3.50 DASA has identified that, for changes that are classified as major solely due to a need to tailor the TCB, continuing to process these as major changes once the tailoring of the TCB has been agreed imposes additional administrative burden without commensurate safety benefit, and can result in a delay to the introduction of safety improvements or capability upgrades. As such, DASA considers it appropriate for these changes to be re-classified to minor, as allowed by DASR GM 21.A.91, and either directly consumed (if subject to prior certification) or approved by a DASR 21J approved organisation holding appropriate privileges.

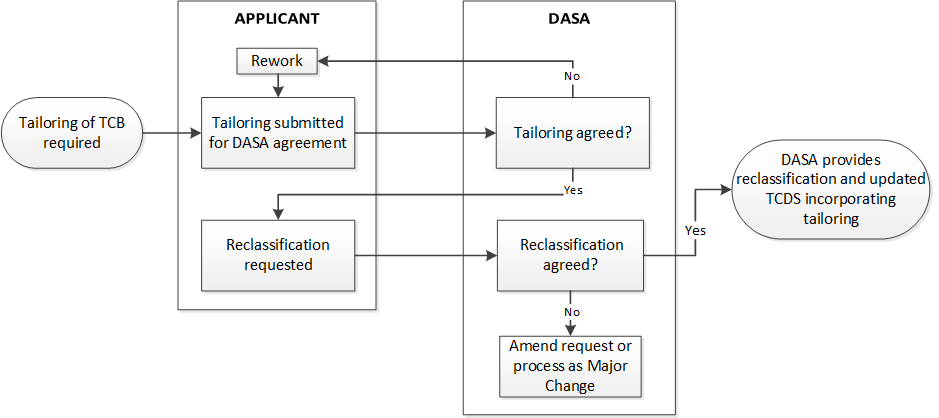

7.2.3.51 Reclassification Process (Figure1). Reclassification is only possible once the tailoring of the TCB has been agreed. An applicant may submit the requests for TCB tailoring and reclassification concurrently, allowing a single DASA response, or the reclassification request may be submitted after the tailoring has been agreed. Requests for reclassification are to be submitted via Letter or Minute to DASA via the DIA Type Certification mailbox (dasa.typecert@defence.gov.au). Requests must be submitted by an organisation that meets the eligibility requirements to apply for a major change under DASR 21 Subpart D (ie the MTC holder or a design organisation that provides MTC holder functions as part of establishing holder capability).1717

7.2.3.52 The applicant must provide confirmation that the design would meet the requirements to be classified as minor if not for the tailoring of the TCB. This may be provided as an assessment from a DASR 21J approved organisation that has privileges to classify changes, or by providing evidence of approval as a minor change under the system of a recognised CAA/MAA with an equivalent classification system.

Figure 1: Process for reclassification when TCB tailoring is required

Compliance Demonstration

7.2.3.53 Compliance demonstration evidence comprises of reports, drawings, specifications, calculations, analysis etc. and provides a record of the means by which compliance with the TCB requirements applicable to the change / MSTC is demonstrated. The applicant shall demonstrate compliance with the applicable TCB requirements either:

through compliance demonstration evidence developed by a MDOA holder (or alternative as agreed by DASA); or

through appropriate evidence of prior certification provided by another CAA / MAA.

7.2.3.54 Refer to the ‘Compliance Demonstration’ evidence guidance in Section 7.2.2 for further information.

Application, Approval / Issue and TCDS Update

7.2.3.55 Application. Upon completion of all activities identified within the certification programme, including development of compliance demonstration evidence and DASA LoI, the applicant provides the required declaration of compliance (refer DASR 21.A.20(d)) and formally applies to DASA for approval of a major change, or issuance of an MSTC, using the DASR Form 31A.

7.2.3.56 Issuance. Upon receipt of the application, DASA assures itself that agreed certification programme activities have been completed, and will approve the major change or issue the MSTC.

7.2.3.57 TCDS. As required, DASA will develop and issue the TCDS update concurrently with the major change approval or MSTC issuance.

DASA Assurance

7.2.3.58 DASA independent safety assurance activities occur throughout the type certification process, and will vary in nature, scope and depth based on each individual project. Key DASA assurance activities for obtaining a major change or MSTC include:

DASA acceptance of the certification programme (refer ‘Certification Programme’ section above).

DASA agreement of the TCB, including tailoring (refer ‘Certification Basis’ section above).

DASA Level of Involvement (LoI) in compliance demonstration activities. The term LoI describes DASA’s involvement in the verification of compliance demonstration. DASA LoI can include review of compliance data and information; testing, or witnessing of compliance testing; or inspections (refer DASR 21.A.33(b)). Depending upon the design, DASA LoI may occur over an extended duration and include on-site witness activities. DASA LoI will have been defined in the certification program (refer ‘Certification Programme’ section above). In all cases, DASA LoI activities must be successfully completed prior to the applicant’s declaration of compliance.

DASA assurance activities related to leveraging prior certification. These activities can be broadly described as DASA review of the evidence and artefacts that support the applicant’s claims that prior CAA/MAA certification can be leveraged (refer to the ‘DASA Assurance’ guidance in Section 7.2.2 for more detailed information).

DASA assurance activities related to the final application. These activities typically include review / evaluation of compliance artefacts submitted as part of the final application, approval of the major change or issue of the MTC, and update of the TCDS as required.

Holder Obligations

7.2.3.59 Given the DASR only allows the MTC holder to be the applicant for a major change to an existing MTC, there are no separate DASR holder obligations for major changes, and the MTC holder must undertake the obligations laid out in DASR 21.A.44 for the MTC, including and all major changes thereto.

7.2.3.60 Obligations for holders of an MSTC are laid out in DASR 21.A.118A . However, given DASA’s policy of issuing all MSTCs to the government MTC holder organisation, and the fact that the DASR 21.A.118A obligations are essentially the same as those ofDASR 21.A.44, the MTC holder simply needs to continue to undertake all obligation laid out in DASR 21.A.44 for the MTC and all MSTCs they hold.

7.2.3.61 Refer to Section 7.4.1 for detailed guidance on the DASR 21.A.44 MTC holder obligations.

Overview

7.2.4.1 Data that is used to accomplish repairs needs to be approved by a suitable and competent organisation. Data may be approved through a repair design approval process where DASA is the certifying authority, or through a process where recognition is used. These two broad pathways are covered by DASR M.A.304, which provides the requirements for data that is used to carry out repairs and modifications:

DASR M.A.304(a) and (b) allow data to be used that has been approved by DASA, and by a Design Organisation approved under DASR 21, respectively. In both cases DASA is the certifying authority and the requirements of DASR 21 Subpart M (Repairs) are applicable.

DASR M.A.304(d) allows for the consumption of data that has been approved within the framework of Authorities recognised by DASA. In this instance the repair approval requirements of DASR 21 Subpart M (Repairs) are not applicable. Direct consumption of data is subject to a suitability assessment (see AMC and GM to DASR M.A.304(d)) in accordance with the scope, conditions and caveats of the relevant recognition certificate.

7.2.4.2 This section is relevant to data for repairs conforming to DASR M.A.304(a) and (b) and provides:

an overview of the repair approval process in accordance with DASR 21 Subpart M (Repairs)

guidance for design organisations and MTC holders regarding DASA’s expectations for repair design development and approval

more detailed guidance in the form of a number of common repair scenarios.

7.2.4.3 Guidance regarding use of repair data in accordance with DASR M.A.304, including consumption of data using recognition provisions, is provided in the Section 8.2.

7.2.4.4 Note that additional general information about Repair Design authorisations is contained in Section 5.3 Annex R.

DASR 21 Repair Design Privileges

7.2.4.5 DASR 21 Subpart J privileges related to repair designs include the privilege to:

classify repairs (DASR 21.A.263(c)(1)),

approve minor repairs (DASR 21.A.263(c)(2)), and

approve certain1818 major repairs (DASR 21.A.263(c)(5)).