8.1.1 This chapter is intended to provide additional guidance on continuing airworthiness regulations to supplement the DASR (DASP Manual Volume 2). This chapter provides additional guidance on aviation safety outcomes that may incorporate compliance with multiple regulations.

8.1.2 The sub-chapters within this chapter are associated with Continuing Airworthiness Management, Maintenance Organisations, Maintenance Licencing and Maintenance Training Organisations. These sub-chapters will also reference, where appropriate, other chapters and sub-chapters within DASP Manual Volume 3 for common aviation safety elements (e.g. occurrence reporting). Other DASP content relevant to continuing airworthiness will also be referenced where possible.

8.1.3 This chapter will contain information that has historically been communicated via Factsheets, Advisory Circulars (ACs) and Frequently Asked Questions (FAQs). In some instances, these historical methods of communicating guidance will remain – particularly for guidance that has a limited period of applicability or when inclusion in DASP Manual Volume 3 is not an intuitive way to communicate specific information. Use of separate Factsheets, enduring ACs and FAQs will be the exception, with the intent that DASP Manual Volume 3 to be the central repository for continuing airworthiness guidance outside of DASR.

8.1.4 The content in this chapter will evolve as the need for additional guidance is identified, with new content and/or new sub-chapters being added over time to support optimal capability outcomes. Accordingly, DASA welcomes any suggestions for future continuing airworthiness guidance noting that awareness training is available via the DASA website.

Introduction

8.2.1.1 The following chapters provide additional guidance on DASR M regulations – they cover activities such as Deferment of Defects, Acceptance of Components and Aircraft Maintenance Programs.

8.2.1.2 The Continuing Airworthiness Management Organisation (CAMO) should be principally located within the aircraft's operational organisation, although the majority of DASR M functions may be outsourced/assigned to other organisations or service providers.

8.2.1.3 Continuing airworthiness management regulation is summarised in the requirements of DASR M.A.101 as ‘This [DASR M] establishes the measures to be taken to ensure that [continuing] airworthiness is maintained, including maintenance. It also specifies the conditions to be met by organisations involved in such continuing airworthiness management’.

8.2.1.4 Referenced content relevant to, but not directly related to, continuing airworthiness will be found in other areas of the Defence Aviation Safety Program including other chapters of DASP Manual Volume 3.

DASR M - Continuing Airworthiness Management

8.2.1.5 CAMOs are required to ensure all their maintenance service providers have access to ICA (and ICA supplements) to the extent necessary for the scope of maintenance services being provided. The scope of continuing airworthiness management activities should be in accordance with the Operating Organisation’s policy and procedures defined in the Continuing Airworthiness Management Exposition (CAME). The CAME is approved by DASA and sets out the procedures, means and methods of how the CAMO intends to comply with the requirements of DASR M. A list of key management positions will be listed in the CAME. The CAME also includes all functions and privileges required to ensure the aircraft are maintained in an airworthy condition, the issue of Military Airworthiness Review Certificates (MARC), and/or changes to the Aircraft Maintenance Programme (AMP). Additional Information on gaining DASA approval to become a CAMO can be found in Chapter 5.3 Annex H –CAMO.

8.2.1.6 CAMOs are responsible for ensuring that maintenance of aircraft is performed by an organisation approved by DASA or another organisation acceptable to DASA. A maintenance organisation is acceptable to DASA if its services are accessed in accordance with the terms of a recognition certificate.

8.2.1.7 Recognition certificates may enable a CAMO to fulfil the aircraft Certificate of Release to Service (CRS) requirement using a maintenance organisation not approved by DASA. These provisions are applicable where DASA has recognised another airworthiness authority in the area of aircraft maintenance. Chapter 6.5, Recognition of Other Aviation Safety Authorities, provides further guidance on the application of recognition.

8.2.1.8 Recognised systems may include an artefact equivalent to an aircraft CRS; however, maintenance organisations may be prevented from issuing a native artefact against a Defence-registered aircraft by legal or policy constraints. Instead, the CAMO should request an artefact that meets the requirements set out in DASR M.A.801.

Airworthiness Directives

8.2.1.9 Airworthiness Directives (ADs) mandate actions to be performed on an aircraft to restore an acceptable level of safety. Furthermore it is mandatory that CAMOs comply with any AD applicable to its aircraft, guidance on Airworthiness Directives can be found in Section 7.4.3 – Airworthiness Directives.

Data for modifications and repairs

8.2.1.10 DASR M.A.304(d) provides for the consumption of data already approved within a recognised airworthiness framework. A CAMO may consume data for repairs and ‘minor’ modifications when the data is produced by an organisation accepted by DASA. An organisation is accepted by DASA if its design products are being accessed in accordance with the terms of a recognition certificate and a suitable procedure. Direct consumption of data is subject to a suitability assessment (see AMC and GM to DASR M.A.304(d)) in accordance with the scope, conditions and caveats of the relevant recognition certificate. The suitability assessment will consider, among other things, the effect of the design classification and its compatibility with the ADF Configuration, Role and Environment (CRE). Additional guidance can be found in Section 7.2.4 – Repair Designs.

Aircraft continuing airworthiness record system

8.2.1.11 An Authorised Release Certificate is necessary for the release to service of either new or used components. It is a document issued by an entity that has the applicable privilege and attests that a new or used component has been produced or maintained in accordance with the approved design data/standard, modification standard or applicable maintenance data. Additional guidance on tracking status of service life-limited components and other usage data for aircraft structures and propulsion systems can be found in Chapter 6.6.4.

Airworthiness review staff

8.2.1.12 Airworthiness review entails a full documented review of the aircraft records and a physical survey of the aircraft. Airworthiness Review Staff are authorised by the CAMO and accepted by DASA to perform Airworthiness Reviews on aircraft which are listed on the CAMO approval certificate.

Introduction

8.2.3.1 This chapter provides additional guidance on acceptance of components – specifically the acceptance of alternate documentation, where components are not supplied with a DASA Form 1 or equivalent recognised document.

8.2.3.2 The introduction of DASRs brought with it a change to the information requirements accompanying components to be consumed on ADF aircraft. DASRs require that components be supplied with a DASA Form 1, or recognised equivalent, that declares the airworthiness of a component.

8.2.3.3 This chapter relates to the acceptance of new and used aircraft components, which are listed by the appropriate design organisation as eligible for installation in/on a product and included in the design data approved by the Authority11. The term components broadly covers any product (other than complete aircraft), part or appliance that is, or is intended by its manufacturer to be, a part of or used in operating an aircraft in flight, or is installed in or attached to a product. This may include any self-contained part, combination of parts, assembly, subassemblies or units, which perform a distinctive function necessary to the operation of the airframe, engine, or propeller, or may include any other instrument, mechanism, equipment, apparatus, software or accessory, including communications equipment.

8.2.3.4 Although alternate artefacts are consumed by a DASR 145 Approved Maintenance Organisation (AMO), DASA requires the relevant CAMO to seek approval for and manage the ongoing validity of alternate artefacts for their respective platforms. Further detail on alternate artefacts can be found in Chapter 8.3.4 – Acceptance of Aircraft Components

What constitutes an ‘alternate artefact’ accepted by DASA?

8.2.3.5 DASA may agree that an AMO may consume an alternate artefact other than a DASA Form 1, or recognised equivalent Authorised Release Certificate, that is produced by an organisation accepted by DASA. A CAMO can seek approval of an Alternate Artefact from DASA using DASR Form 155 – Application for Acceptance of Alternate Artefact. AMC to DASR M.A.201(g) and M.A.802(c) provide detail on when an alternate artefact would be acceptable. Chapter 8.3.4 – Acceptance of Aircraft Components provides further detail.

Consumption of United States (US) Department of Defence (DoD) products

8.2.3.6 There has been confusion with consumption of US DoD supplied products where associated documentation, such as DD Form 250, does not meet the requirements of a DASA Form 1 or recognised equivalent. The DASR provide a path for the regulated community to accommodate the consumption of products where the product supplied does not meet the requirements of a DASA Form 1. This is:

AMOs and CAMOs comply with DASR 145.A.42 and DASR M.A.201 (g) (e.g. via direct recognition or DASR Form 155 Application for Acceptance of Alternate Artefact).

Where (a) above is not reasonably practicable, CAMOs can develop a procedure within their exposition to demonstrate to DASA how these products can be consumed whilst maintaining an equivalent level of protection. DASA will then assess this procedure against the requirements of DASR GR.80(b), and if appropriate, approve the procedure for use.

Where (a) is not reasonably practicable, and an equivalent level of protection cannot be ensured (b), CAMOs can develop a procedure within their exposition to demonstrate to DASA how these components will be consumed; accompanied by a demonstration that the resultant risks are appropriately managed by the applicable MAO. DASA will then assess this procedure against the requirements of DASR GR.80(c), and if appropriate, allow the use of the procedure.

Introduction

Aircraft Maintenance Programme (AMP)

8.2.4.2 DASR M.A.302(a) requires that maintenance of each aircraft shall be organised in accordance with an AMP. The AMP encompasses the actual maintenance programme in its entirety. An AMP provides the scheduled maintenance tasks, their associated maintenance procedures and standard maintenance practices that are applied to the maintenance of an aircraft. The RP, which continually reviews the applicability of the AMP to the aircraft and operator, is also considered a part of the AMP.

Introduction

Background

8.2.6.2 Under certain conditions the required level of safety can be maintained with specific aircraft components being unserviceable, for a limited period of time, until repairs can be made. Many aircraft also have equipment installed that is not required for safe operation under certain operating conditions (e.g. aircraft with multiple VHF radios can operate with single radio if operations do not require the use of the systems associated). Equipment, such as entertainment systems, galley equipment, mission equipment or systems, may have no impact of flight safety.

8.2.6.3 An MMEL is a document created specifically to permit the continued operation of an aircraft type with unserviceable equipment, based on the aircraft type certification. An MEL consists of an approved list of the specific unserviceable equipment for a particular aircraft by serial and registration mark, based on the MMEL and the Operator’s Configuration, Role and operating Environment (CRE).

8.2.6.4 An MEL can be used as the first step in a defect management process in accordance with procedures developed by the CAMO and approved by the DASA to meet the requirements of DASR M.A.301 (a) 2, for the deferral of defects.

EASA Rules for Master Minimum Equipment List (CS-MMEL)

DASA Regulatory Basis

8.2.6.6 DASR GM 21.A.15(a) - Application for a Military Type Certificate may include the MMEL as Operational Suitability Data (OSD) that may be approved as part of Type Certification and form part of the Military Type Certificate (MTC) .

8.2.6.7 DASR M.A.301 Continuing airworthiness tasks, refers to MEL and Configuration Deviation List (CDL) for use in the deferment of defect rectification.

8.2.6.8 DASR AO Gen.05 Management of OIP, ORO.05 Conduct of Flying Operations and ORO.30 Flight Authorisation support discharging flight operations requirements referred to in this chapter.

Configuration Deviation List

8.2.6.9 A Configuration Deviation List (CDL) is a listing of regulator-approved non-structural external parts that may be missing but the aircraft remains airworthy. A CDL provides options to dispatch an aircraft for flight when listed parts may be missing, provided the necessary performance corrections are adhered to (including limits or restrictions if required and specified rectification periods). Refer DASR M.A.301(a)2 and associated AMC/GM.

8.2.6.10 CDLs are part of the certified type for any civil derivative aircraft (certified by the European Aviation Safety Agency (EASA) or the Federal Aviation Administration (FAA)). Within the ADF context, as part of Military Type Certification, the CDLs are presented as part of the Aircraft Flight Manual (AFM) for approval during Type Certification. Usually, they are contained in a standalone section of the AFM. The AFM is approved as part of Military Type Certification (DASR 21 Subpart B) and changes would be approved under (DASR 21 Subpart D).

8.2.6.11 The CDL should not be confused with the Minimum Equipment List (MEL). While the MEL describes the limitations of aircraft operation in case of a system being inoperative or having malfunctioned (e.g. transponder failure), the CDL deals with situations where external parts of an aircraft are missing (e.g. fairings, aerodynamic seals or panels).

MMEL

What is a MMEL?

8.2.6.12 A MMEL is a document created specifically to permit the continued operation of an aircraft type (e.g. C-130J-30) with unserviceable equipment. It is a list of items of equipment that may be temporarily unserviceable under certain conditions and limitations, while still maintaining the level of safety intended in the design standards. The MMEL does not take into account the operating circumstances of individual operators of that type. The MMEL cannot, in itself, be regarded as providing operational permission. It can, however, be the basis for the development of an individual Operator’s MEL.

MMEL Characteristics

8.2.6.13 Aircraft Type. MMEL relief for a particular item may be unique to a specific aircraft type. Therefore, MMEL relief for an item for one aircraft type may not be the same as the relief allowed for the same item found in another aircraft type.

8.2.6.14 Items required by an Airworthiness Directive (AD) are prohibited. An MMEL will not include items that an AD requires to be operative, unless the AD specifically allows them.

8.2.6.15 Variable Number of Items Required for Dispatch. A MMEL may depict a variable number of items required for dispatch based on various makes and models of the same series aircraft. The MMEL must clearly articulate which makes and models each MMEL item is applicable to.

8.2.6.16 Multiple Versions of the Same Item. A MMEL may contain multiple versions of particular items (e.g., very high frequency (VHF) communications systems and fire extinguishers) that are installed on different models or series of the aircraft covered by the MMEL. The MMEL must clearly articulate which versions each MMEL item is applicable to.

8.2.6.17 Repair Categories. A MMEL will contain a repair category for each item. Each repair category allows for a certain amount of time until repairs must be accomplished.

8.2.6.18 Prohibited Items. A MMEL will not include items of the aircraft that are required for basic flight (wings, flaps, rudder, etc.), nor will it include instruments and equipment required for specific operations.

What is a MEL?

8.2.6.19 A MEL is a document created specifically to manage the continued operation of an aircraft with unserviceable equipment consisting of an approved list of the specific unserviceable equipment for a particular make and model of aircraft by serial/production number and registration mark (e.g. C-130J-30, 5440, A97-440) as applicable. Its use is authorised by accepting the associated application procedures contained in an operator’s Continuing Airworthiness Management Exposition (CAME) and/or operations manual, or other appropriately documented procedures.

MEL Transferability

8.2.6.20 An approved MEL for an aircraft is a non-transferable document, i.e. if the MAO of the aircraft changes, then a new approval for the MEL is required even if the aircraft retains the same registration mark.

8.2.6.21 If an aircraft moves from one Military Air Operator Certificate (MAOC) holder to another, the new MAOC holder cannot automatically use the approved MEL for the aircraft. The new MAOC holder will be authorised by DASA only if they have acceptable associated application procedures contained in their CAME and/or operations manual and have assessed the operator's CRE.

MMEL/MEL Considerations for Use

8.2.6.22 The MMEL/MEL is an alleviating document. Its purpose is not to encourage the operation of aircraft with unserviceable equipment. It is never desirable that aircraft continue operations with unserviceable equipment. Such operations are permitted only as a result of careful analysis of each item to ensure that the required level of safety is maintained. A fundamental consideration in permitting the operation of aircraft with unserviceable equipment is that the continued operation of an aircraft in this condition is to be eliminated or otherwise minimised so far as reasonably practicable (SFARP).

Invoking the MEL

8.2.6.23 The Aircraft Captain or appropriately licenced and authorised Military Aircraft Maintenance Licence (MAML) holder invokes the MEL on behalf of the CAMO. It is the decision of the Aircraft Captain to accept the aircraft for flight with unserviceable systems or equipment listed in the MEL. The overriding principle is that, notwithstanding the provision of an approved MEL, a MAML holder should not release an aircraft for flight, and the Aircraft Captain should not accept an aircraft for flight, if it is considered unsafe for a particular flight.

8.2.6.24 A MAO may authorise Aircraft Captains to invoke MEL items through provisions in the Operations Manual. Where an Aircraft Captain is not authorised to invoke a MEL item the Aircraft Captain is to refer to local procedures for actions required to invoke the MEL item.

MMEL Development Options

8.2.6.25 Existing CAA/MAA MMEL as part of Operational Suitability Data (OSD). As part of the introduction of a new type to Defence the initial certification package may contain a MMEL that has been developed by the OEM as part of the OEM state of design certification process. This MMEL document can be submitted as OSD, as part of the Australian MTC certification package and be assessed for approval as the DASA approved MMEL. Similarly, for an existing type with no DASA approved MMEL, an existing Civil Aviation Authority (CAA) / Military Aviation Authority (MAA) approved MMEL may be submitted for approval as a change to the type certificate.

8.2.6.26 In both cases above, foreign CAA/MAA approval of a MMEL does not constitute automatic approval under DASRs. DASA issues its own sovereign Military Type Certificates (MTC) for each aircraft type and does not ‘accept’ foreign civil or military TCs. Therefore, in order for a MMEL to be approved under DASRs it must be approved under the initial issue of, or as a change to, the DASA issued MTC and be included on the DASA issued Type Certificate Data Sheet (TCDS).

8.2.6.27 MEL submitted in lieu of MMEL. If the operator has access to an existing, or has developed, a MEL for the type, for which no MMEL exists, the operator may submit the MEL through the Military Type Certificate Holder (MTCH), for assessment as a MMEL. If the MEL is submitted, DASA will consider it a MMEL submission and assess it as such. It may then be used as the basis for acceptance as a MEL.

8.2.6.28 Development of a new MMEL. A MTCH may elect to submit a new MMEL to DASA for approval. DASA does not stipulate any specific format and/or contents of a MMEL. However, the Certification Programme must propose an appropriate Certification Basis that the MMEL will comply to, and that may include content and format requirements. Establishing the Certification Basis early and following the associated format will avoid delays in assessment and approval of the MMEL.

8.2.6.29 Suitable Certification Specifications. The Certification Programme should be submitted to DASA, proposing a Certification Basis for the MMEL. The following two certification specifications will likely be suitable for development of MMELs:

EASA CS-MMEL. CS-MMEL is the Certification Specification (CS) mandated by EASA for MMEL development and is likely to provide an acceptable basis for MMEL approval for Defence aircraft.

FAA FOEB process. FAA policy for MMEL approval is through the Flight Operational Evaluation Board process. MMEL document templates, guidance on specific systems, general format requirements, and guidance on justification requirements are available on the FAA FSIMS website. (Reference ICAO Manual – MMEL/MEL5 and Flight Standards Information Management System).

8.2.6.30 Alternate Certification Bases may be proposed in the Certification Programme but will require further justification.

MMEL development process

8.2.6.31 As the MMEL forms part of the Military Type Certificate, any MMEL change is to be classified IAW the guidance in DASR 21.A.91. On initial issue of the MMEL or identification of a MMEL change as Major, the Major Change to Type Certificate process as per DASR 21 subpart D applies. Minor changes to MMELs are to be processed IAW DASR 21.A.95. This process is depicted at Appendix 2.

8.2.6.32 MMEL Change Classification Criteria. The following guidance for classification of MMEL changes elaborates upon the generic classification advice in GM to DASR 21.A.91.

8.2.6.33 Conditions requiring classification of a MMEL change as Major:

Where the change requires an adjustment of the MMEL certification basis;

Where the applicant proposes changes to the Means of Compliance (MoC) with the requirements for the MMEL certification basis (i.e. MMEL safety assessment methodology);

Where the extent of substantiation data and the degree to which the substantiation data has to be assessed and evaluated is considerable, in particular but not only when:

The substantiation data involving review of failure conditions that are classified as hazardous or catastrophic has to be evaluated;

The assessment of the failure effects (including next worst failure/event effects) on crew workload and the applicable crew procedures has to be evaluated; or

The capability of the aircraft to perform types of operation (e.g. Defence Long Range Operations (DLRO), Instrument Flight Rules (IFR)) under MMEL is extended.

8.2.6.34 Conditions where the MMEL change can be considered Minor:

Modifications to an item/s when:

The change is only to the applicability of an item for configuration management purposes;

The change is the removal of an item;

The change is an increase in the number of items required for dispatch; and

The change is a reduction in the rectification interval of an item.

Addition of a new item when:

It is considered as non-safety related IAW FAA MEL Requirements for 14 CFR Parts 91 Subpart K (Part 91K), 121, 125, 125 LODA, 129, and 135 Operations CS-MMEL GM2 MMEL.110; or

It is indicated as eligible for minor change classification in FAA MEL Requirements for 14 CFR Parts 91 Subpart K (Part 91K), 121, 125, 125 LODA, 129, and 135 Operations, GM1 CS MMEL.145.

8.2.6.36 If the conditions and limitations applied against a MMEL item are assessed as insufficient to fully eliminate the associated risk, or an Equivalent Safety argument cannot be made that the risk meets the level of safety inherent in the applicable design standards in the aircraft Type Certification Basis (TCB), the MMEL item is NOT to be included in the MMEL.

8.2.6.37 Operational endorsement should be sought from the MAO (e.g. Hazard Tracking Authority or Standards Officer (STANDO) for any operational conditions or limitations identified against MMEL items. The MTCH in developing the MMEL considers the operational conditions/limitations of the aircraft against the type certification. The MMEL operational procedures are not specific to an individual Operator’s Configuration Role and operating Environment (CRE).

8.2.6.38 Relief from Development of Compliance Demonstration Evidence. Relief from the requirement to develop compliance demonstration evidence can be sought on an item by item basis for MMELs. The requirements for leveraging prior certification from another CAA/MAA as per AMC to DASR 21.A.20 still apply when relief is applied in this manner.

MMEL approval process

8.2.6.39 Initial Type Certification

The applicant for initial DASA MTC would submit the MMEL as part of the application package.

8.2.6.40 MMEL for an aircraft with an existing DASA MTC

An MTCH submitting a MMEL for DASA approval must do so in accordance with the Change to Type Design process as described in DASR 21

Refer to Appendix 2: for the process flow to seek DASA approval of a MMEL.

Developing a MEL using an existing/relevant MMEL

8.2.6.41 DASA do not stipulate any specific format and/or contents of a MEL. Using an international recognised format could avoid delays in assessing the MEL. In the development of an MEL, DASA recommends that the MEL be developed in accordance with international standards as referenced in the Certification Programme from the MMEL (detailed above).

8.2.6.42 The MEL should be developed from the latest issue of the applicable MMEL on an item-by-item basis and keeping in view the relevant regulatory requirements.

8.2.6.43 If an operator chooses to add items that are not found in the MMEL (due to its particular type of operation) an assessment of those items must be carried out. This assessment is required to ensure that these items do not affect the design standards or safe operation of the aircraft and are not in conflict with the flight manual and any DASR requirements. Refer to the International standards as referenced in the Certification Programme from the MMEL for guidance on how to assess the criteria for these items.

8.2.6.44 In general, a MEL should be as, or more, restrictive than the applicable MMEL for the type of aircraft. If a certain item(s) of the applicant’s MEL is less restrictive than the applicable MMEL, DASA will require an extensive qualitative and/or quantitative analysis to substantiate the proposed departure from the MMEL.

MEL Development with no MMEL

8.2.6.45 If a platform has no MMEL or MEL available from the manufacturer or other CAA/MAA and the operator wants to utilise the flexibility that a MEL affords, the Operator may choose to engage the MTCH to develop a MMEL from previously available deferment options.

8.2.6.46 The MMEL should be developed in accordance with the guidance provided earlier in this chapter.

8.2.6.47 Once the MMEL is approved by DASA the operator can seek approval of the MMEL for use as an MEL from DASA.

MEL approval process

8.2.6.48 An Operator submitting a MEL for approval must provide DASA with:

A minute of application from the CAMO requesting approval of the MEL;

Digital access to a copy of the proposed MEL;

All OIP created for use of the MEL; and

If the MEL has no associated DASA approved MMEL, the MEL must be submitted for approval as a MMEL.

8.2.6.49 A MEL may cover more than one aircraft of the same type. However, all differences in the equipment/systems installed, if any, should be clearly identified by the aircraft registration mark.

8.2.6.50 Refer to Appendix 1: for the DASA process flow of MMEL/MEL approval.

Application for amendment to the MEL

8.2.6.51 Amendments to MELs are either mandatory or voluntary, depending upon the particular circumstances. Mandatory amendment of a MEL is required either:

When the applicable MMEL is amended so as to become more restrictive; or

When required by DASA in light of in-service experience.

8.2.6.52 Voluntary amendment of a MEL may be carried out when either:

The MMEL is amended so as to become less restrictive; or

As required by the operator, provided the proposed change is no less restrictive than the MMEL; or

Regulatory changes occur.

8.2.6.53 An application for amendment to an approved MEL, together with appropriate substantiation, should be forwarded to DASA.

MMEL/MEL Development Considerations

Operations and maintenance procedures

8.2.6.54 The objective of operations ((O)) and maintenance ((M)) procedures is to provide everyone using the document with clear and concise directions on how they are to proceed in case of unserviceability. The (O) and (M) procedures form part of the approved MEL.

8.2.6.55 (O) Procedures: Where the (O) symbol appears in the MMEL, an operations procedure must be developed that provides clear direction to the flight crew. These procedures may be included in the MEL. Where they are not included in the MEL, they must be available to the aircrew in another document that is always available to the aircrew (i.e. an operations manual or in an approved electronic form). In these cases, the MEL shall refer to a section of the appropriate document(s).

8.2.6.56 (M) Procedures: The MMEL may identify items that require a maintenance procedure. If this is the case, the operator must ensure that relevant (M) procedures have been developed for the MEL. These procedures must provide clear direction to the maintenance personnel.

Procedures for the use and guidance of flight crews and maintenance personnel

8.2.6.57 The operator must establish procedures for the use and guidance of flight crews and maintenance personnel, in relation to the MEL. These procedures must agree with those in the operator’s CAME, Aircraft Maintenance Program (AMP), operations manual, and other operating documents. These procedures should include, but are not limited to, procedures for:

Deferring rectification action or invoking MEL item(s) for unserviceable equipment;

Placarding requirements as per the MEL;

Ensuring that a dispatched aircraft with an invoked MEL item(s) complies with the limits and conditions of the MEL;

Ensuring that existing deferred defects / MPTF / Command Clearances do not impact invoking of MEL provisions;

Controlling categorised repair intervals; and

The training of organisations personnel who are responsible for compliance with MEL procedures.

8.2.6.58 Procedures for invoking MEL items are normally contained in the operator’s CAME, operations manual or an alternative document. Prior to issuing a MEL approval, DASA will ensure that the MEL references these procedures in the CAME, operations manual or similar document, if not already included in the MEL. If no procedures for the invoking of MEL items exist within the operator’s organisation, then DASA will, in addition to vetting the MEL, require amendment to the CAME/MOE and/or operations manual.

8.2.6.59 A placarding procedure should be established and set out in the CAME/MOE and operations manual or, at least, within the approved MEL document.

8.2.6.60 When invoking a MEL item, the person responsible must:

Identify, in the aircraft technical log or appropriate document/maintenance information system, that this action has occurred;

Identify the item with its MEL number; and

Ensure that an unserviceable label is placed in an appropriate location (where applicable).

8.2.6.61 A procedure documenting the above requirement in the appropriate operator’s documentation is acceptable for compliance purposes.

Repair intervals

8.2.6.62 Each item of a MEL must be repaired within the specified repair interval. These intervals are set to limit the maximum time an aircraft may fly with an unserviceable item(s) of equipment, and are designated Category ‘A, B, C or D’. The definition of repair intervals should align with the selected certification basis for the MMEL as defined at para 8.2.6.29.

8.2.6.63 The operator must establish procedures whereby the maintenance support periodically reviews the deferred items. This is done to ensure that any accumulation of deferred items neither conflict each other nor present an unacceptable increase in crew workload. Notwithstanding the categorisation of item repair intervals, it should be the aim of each MEL document holder to ensure that unserviceable items are repaired as quickly as possible.

Repair interval extension

8.2.6.64 Each operator’s MEL management program needs to contain procedures for controlling extensions to item repair intervals. Procedures must include the limitations of each extension and the method by which the operator approves an extension.

MEL training program

Training Requirement

8.2.6.65 The operator should as part of the introduction of a process for the use of a MEL develop a MEL training program for maintenance personnel and flight crew, which should be in place prior to an operator commencing operations with a MEL. The operator, when required, should conduct recurrent training, or put in place a controlled method to alert staff to any changes in MEL procedures. This will ensure company personnel remain current with those procedures.

Maintenance Personnel Training

8.2.6.66 The training for maintenance personnel should include those sections of the CAME procedures dealing with:

The use of, and compliance with, the MEL;

Placarding of unserviceable equipment;

Return to service of an aircraft;

Dispatching an aircraft; and

Any other MEL related procedures.

Flight Crew Training

8.2.6.67 The flight crew training should include, but not be limited to, the following:

The purpose and use of a MEL;

Instruction on operator’s procedures for the use and guidance of flight crew;

The process and procedures required for supervision and flight authorisation; and

The Aircraft Captain’s responsibility with respect to the above procedures.

Introduction

8.3.1.1 This section provides additional information and guidance to DASR 145 Approval Holder Organisations and those organisations that are applying for approval under DASR 145. Further guidance on applying for a Maintenance Organisation approval can be found in Section 5 Annex G – AMO.

8.3.1.2 For information on maintenance service providers that are approved though other means (i.e. not DASR 145 approval), refer to Chapter 6.5, Recognition of other Aviation Safety Authorities and to Chapter 8.2, Continuing Airworthiness Management.

8.3.1.3 This chapter does not include information already presented at Volume 2 (DASRs), but represents additional guidance material. Referenced content relevant to, but not directly related to, continuing airworthiness will be found in other areas of the Defence Aviation Safety Program including in other chapters of DASP Manual Volume 3.

DASR 145 – Requirements for Maintenance Organisations

8.3.1.4 The Defence Aviation Safety Regulations (DASR) requires individual DASR 145 Approved Maintenance Organisations (AMOs) to define their own line and base maintenance activities in their Maintenance Organisation Exposition (MOE).The scope of maintenance of aircraft and components activities should be in accordance with the Maintenance Organisation’s policy and procedures defined in the MOE.

Acceptance of components

8.3.1.5 The AMO must ensure that components are accompanied by appropriate documentation attesting to the legitimacy of the component’s maintenance or production history. This is underpinned by the regulatory requirement for the AMO to obtain a DASR Form 1 or equivalent documentation prior to fitment of such components. Where an unserviceable or unsalvageable component is the subject of an occurrence report, the DASR 145 organisation should quarantine the component until the investigation has determined that the component is not required to be retained for further examination Additional information can be found in Chapter 8.3.4 – Acceptance of Components.

Certification of maintenance

8.3.1.6 Maintenance carried out on an aircraft, its systems and its components must be certified at completion and prior to its return to service. The instrument used to achieve this outcome is the Certificate of Release to Service (CRS) that must be issued at the completion of maintenance and before the next flight. Additional guidance for Certification of maintenance can be found in Chapter 8.3.3 - Certification of maintenance.

Introduction

8.3.2.1 This chapter provides additional guidance on the performance of maintenance including guidance on line and base maintenance, and specialist maintenance qualifications.

8.3.2.2 Not all maintenance personnel in a DASA 145 MO need to be authorised as certifying and/or support staff. Acting as certifying or support staff is intrinsically a hands-off activity (in contrast to the performance of maintenance being physical hands-on aircraft maintenance). DASA 145 MO personnel perform maintenance under a Task Sign-Off (TSO) authorisation. On-aircraft TSO is overseen, managed and later certified (issue of CRS) by authorised certifying staff.

8.3.2.3 Except for a few speciality areas (e.g. composite repairs), DASA does not prescribe knowledge / experience standards for the performance of maintenance. On-aircraft TSO provides an attestation that the maintenance task has been carried out to the required standard.

8.3.2.4 A DASA 145 MO has flexibility to determine their own Qualification, Training and Experience (QTE) requirements when assessing and authorising personnel to perform the vast majority of maintenance (less some specialist qualifications where DASA will specify acceptable means of compliance). It is up to a DASA 145 MO to determine the scope that maintenance personnel can be authorised to perform, and may also mandate the level of supervision maintenance personnel require – noting supervision can be performed by authorised persons who are not necessarily certifying staff – see GM2 DASR 145.A.35(e). Maintenance personnel do not need to hold a MAML, of any category, to be authorised to perform maintenance.

8.3.2.5 DASA oversight of DASA 145 MOs, in the context of foreign trained maintenance personnel employed to perform maintenance, will focus on the procedure that identifies knowledge and experience requirements, to determine the authorised scope of maintenance and supervision required.

8.3.2.6 For information on maintenance service providers that are approved though other means (i.e. not DASR 145 approved), refer Chapter 6.5, Recognition of other Aviation Safety Authorities and Chapter 8.2, Continuing Airworthiness Management.

8.3.2.7 For information on the performance of maintenance relates to the certification of maintenance, see Chapter 8.3.3 – Certification of Maintenance.

Line and Base Maintenance

Background

8.3.2.8 The Defence Aviation Safety Regulations (DASR) requires individual DASR 145 Approved Maintenance Organisations (AMOs) to define their own line and base maintenance activities in their Maintenance Organisation Exposition (MOE). Feedback from the regulated community indicates that there is insufficient DASR guidance on what types of activities constitute line and base maintenance. This chapter describes types of maintenance activities constituting line and base maintenance and describes the intended outcomes in relation to line and base maintenance as interpreted by DASA.

8.3.2.9 The DASR Glossary of Terms describes line and base maintenance as:

Line Maintenance: Carried out before flight to ensure that the aircraft is fit for the intended flight.

Base Maintenance: Maintenance tasks falling outside the criteria for line Maintenance.

8.3.2.10 A more detailed definition of aircraft line maintenance is provided in AMC 145.A.20, together with a list of activities which “may” be considered as line maintenance. The word “may” is used because it is not possible to establish a provision giving a strict demarcation between line and base maintenance, having general applicability to all cases.

8.3.2.11 To assist civil MOs, the European Aviation Safety Agency (EASA) has developed an EASA 145 User Guide chapter on ‘Privileges and limitations of line maintenance’. This guide provides detailed guidance on what constitutes line and base maintenance. This Annex is has been developed based on the EASA User Guide to provide an EASA aligned approach to guide DASR 145 MOs in defining line and base maintenance.

Organisation responsibilities

8.3.2.12 The maintenance organisation should ensure prior to any intended maintenance event that the activity can be carried out under its line maintenance scope of approval (refer to AMC 145.A.20) and does not fall under paragraph 14 ‘Examples of maintenance activities considered to be base maintenance’ of this Chapter.

8.3.2.13 This assessment may not need to take place each time, but be based on already established MOE procedures (i.e. the fact that a daily check is a line maintenance task is obvious and does not need to be assessed each time).

8.3.2.14 Even if this assessment confirms that the activity is line maintenance, the maintenance organisation should also verify if this activity requires other means than the ones already in use at a line maintenance location.

When to assess the maintenance activity

8.3.2.15 The maintenance organisation`s assessment to decide if any maintenance event falls within the definition of line or base maintenance, may be needed in two different situations:

for an initial/change of approval, when evaluating the scope of work the maintenance organisation is applying for (refer paragraph 11); or

for an already approved maintenance organisation, when evaluating if maintenance requested by the customer (e.g. a new Service Bulletin (SB), defect rectification or work package requested by the customer, etc.) falls within the approved line maintenance scope of work.

Assessment of the intended scope of work (initial/change of approval)

8.3.2.16 It is the responsibility of the maintenance organisation to demonstrate to DASA that the intended scope of work may be carried out in a line maintenance environment, under its line maintenance scope of approval. The main criterion for this assessment is to consider the level of maintenance to be carried out under the line maintenance scope of approval, where the following general criteria apply:

Trouble shooting, Defect Rectification. Those unscheduled tasks required for the daily operation of an Aircraft and not falling under ‘Examples of maintenance activities considered to be base maintenance’;

Minor scheduled line maintenance. Those scheduled tasks not exceeding the weekly check as specified in the Aircraft Maintenance Program (AMP);

Scheduled checks. Those scheduled tasks which exceed the weekly check (or equivalent as determined by the Authority). In this case, the organisation needs to analyse each of the routine tasks intended to be included in the line maintenance scope of work and identify a clear limit. This assessment needs to be performed using the Type Certificate Holder (TCH) data such as the manufacturer’s Maintenance Planning Document (MPD), and/or the operator’s AMP. The outcome of this exercise is to identify the intended limitation of the line maintenance scope of approval, in terms of scheduled maintenance checks. In particular, the following is expected:

Depending on the AMP logic (i.e. MSG 2, MSG 3, etc) a clear limitation to the line maintenance scope of work may be normally expressed in one of the following ways:

“up to and excluding X check” (i.e. X= R1, R2, etc) for a MPD, where letter checks are identified;

“up to and excluding “X FH / Y FC / Z calendar time”, for a MPD, where progressive task intervals are defined in terms of FH/FC/calendar time (i.e. X=3000FH, Y=750 FC, Z=12 months, etc);

The identified limit, to be indicated in the MOE, should be such that all the related routine/scheduled tasks are excluding any of the tasks listed in ‘Examples of maintenance activities considered to be base maintenance’

A “decision making process” (refer paragraph 12 for example) needs to be established in the MOE in order to assess

(the need to access the hangar (even if the activity is permitted under a line maintenance scope of approval), considering in particular the type of aircraft, the maintenance event type/complexity, the environmental and weather conditions;

any work order / work package received from the customer operator to ensure it may be fully performed under a line maintenance scope of approval, taking into account additional works to the original work package that may be added, leading out to the line maintenance scope of work, such as:

addition of previously deferred maintenance tasks; or

defects raising from the routine tasks (these defects are not known in advance, however, the related risk in terms of number and level of defects needs to be taken into account and estimated in advance).

8.3.2.17 Example of ‘decision making process’. A R1 maintenance check on the Boeing Business Jet (BBJ) aircraft type is normally considered “line maintenance” when the routine tasks are assessed as per the manufacturer MPD/operator AMP. Therefore a maintenance organisation may be approved to perform this check under a line maintenance scope of work. However, a work order to perform the “R1 check”, where the customer operator would request the performance of works in addition to the “R1” routine tasks, such as the addition of Airworthiness Directives (ADs), SBs, deferred tasks, will need to be carefully assessed by the maintenance organisation with the use of the “decision making process”.

8.3.2.18 This type of maintenance check may easily fall within the examples given in Paragraph 14 ‘Examples of maintenance activities considered to be base maintenance’ having the result to be considered as base maintenance and being outside the maintenance organisation scope of work. In such a case, the outcome of the “decision making process”, may be for example:

The impossibility to accept such work order from the operating organisation, being outside the scope of work of the maintenance organisation; or

to agree with the operating organisation a revised work order, to remove the works which have been identified as base maintenance tasks (e.g. removal of a SB which was requiring extensive disassembly and modification of flight controls, etc.).

Examples of maintenance activities considered to be base maintenance

8.3.2.19 When any of the following tasks are required to be carried out (regardless if contained in a scheduled maintenance check or arising from a defect rectification/AOG situation), a base maintenance scope of approval is needed:

High number of different type of tasks to be carried out, even if taken singularly those tasks may still fall under the definition of line maintenance (i.e. a combination of routine task cards, non-routine task cards issued following defects discovered during the check, out of phase tasks, deferred items from previous maintenance, minor repairs, minor modifications, component replacement, etc). Such cases require base maintenance production planning support and/or a base maintenance release to service process (category C Certifying Staff supported by B1/B2 support staff) in order to ensure that all the maintenance ordered has been carried out before issuing the CRS;

Replacement of any major component where the related maintenance procedures address the need of a hangar environment requiring special ground support equipment and/or structured production planning and/or complex and lengthy maintenance, such as for example a full landing gear replacement, simultaneous replacement of two engines, etc;

Any scheduled maintenance task (i.e. routine task from the AMP) which requires extensive disassembly of the aircraft and/or extensive in depth inspection;

Major repairs and/or major modifications;

Trouble shooting and/or defect rectification requiring special ground support usually relevant to base maintenance (e.g. special equipment, structured production planning, complex and lengthy maintenance);

A scheduled maintenance event, which in the planning phase has been already identified as significant in terms of duration and/or man-hours (i.e. an aircraft down time above 72 hours or four shifts, whichever is less);

A work package requiring a complex team composition in terms of high number and categories (avionic, structure, cabin, NDT qualification and skills, etc) of staff involved per shift; or

The management of the event by B1 and B2 support staff and the release by a C certifying staff.

8.3.2.20 For AMOs that do not hold a base maintenance approval, the AMO remains responsible to ensure that even if each individual work order constitutes a line maintenance activity, a maintenance event cumulating several of these work orders remains within the AMO’s line maintenance scope of approval.

Assessment of maintenance task by an already approved maintenance organisation

8.3.2.21 For AMOs that do not hold a base maintenance approval, the AMO remains responsible to assess if any maintenance requested by the operating organisation falls within the approved line maintenance scope of work. This assessment is expected to be performed based on the “decision making process” described above.

Specialist Task Qualifications

8.3.2.22 Introduction. DASR 145.A.30(f) relates to MO personnel who carry out Non-Destructive Testing (NDT) and other specialised tasks such as composite repair and welding. Definitions pertaining to the scope of DASR 145.A.30(f) are as follows:

Particular non-destructive test means any one or more of the following; Penetrant Testing (PT), Magnetic Testing (MT), Eddy current Testing (ET), Ultrasonic Testing (UT), Radiographic Testing (RT), Thermographic Testing (TT) and Shearographic Testing (ST) methods (refer GM 21.A.30(f)). Boroscoping and other techniques such as manual tap testing are non-destructive inspections rather than non-destructive testing (refer AMC 145.A.30(f)).

8.3.2.23 DASR 145.A.30(f) requires that the MO must ensure that personnel who carry out NDT and other specialised tasks are appropriately qualified in accordance with recognised standards. The following paragraphs provide guidance on the standards recognised by DASA and other aspects of personnel training and certification.

8.3.2.24 It should be noted that the training standards required to perform specialist tasks might exceed the training standards to certify this maintenance. For example a licence persons with no structural repair exclusions could certify for a complex composite repair but may not be qualified to perform the maintenance. In this case the certifying staff may require separate specialist supervision in order to very the maintenance has been performed properly.

Qualification of Personnel for Non-Destructive Testing (NDT)

8.3.2.25 Recognised NDT Qualification Standards. DASA recognises the following standards for qualification of personnel who carry out and/or control NDT of aircraft structures and/or components (refer DASR 145.A.30(f)):

European Standard EN4179 - Qualification and Approval of Personnel for Non-destructive Testing is the primary NDT standard recognised by DASA

NAS410 – NAS Certification & Qualification of Non-Destructive Testing Personnel is also recognised by DASA.

8.3.2.26 NAS410 is the only NDT qualification standard DASA recognises as being equivalent to EN4179. Organisations that wish to use an alternative NDT personnel qualification system should apply to DASA with a proposed Alternate Means of Compliance (AltMoC). Note that Australian Standard AS3669 and ATA Spec 105 have been assessed as non-equivalent to EN4179 (refer GM 145.A.30(f)) and will not be approved as AltMoC by DASA.

8.3.2.27 NDT Personnel Training and Certification. The appointed NDT Responsible Level 3 (RL3) for each DASR 145 MO is responsible for establishing a training and certification system which supports awarding of task authorisations to NDT personnel working within the DASR 145 MO. This training and certification system should be established in line with EN4179. In cases where the minimum training and experience hour requirements stipulated in EN4179 Section 6 do not align with Defence’s requirements, a competency based training program can instead be used, provided the course program is approved by DASA. Refer to GM 145.A.30(f).

8.3.2.28 For details of the approach to NDT training and certification implemented in support of ADF DASR 145 MOs, refer to Volume 3 Section 4.2.3.

8.3.2.29 Appointment of NDT Responsible Level 3. AMC 145.A.30 stipulates that the NDT RL3 for a DASR 145 organisation is a nominated management position, and is accepted by DASA through a DASR Form 4 application. Each DASR 145 organisation should only have one appointed NDT RL3. The DASR Form 4 requires applicants to submit details and supporting documentation of relevant qualifications and experience. Specific to NDT RL3 applications:

Applicants are requested to provide a copy of all personnel certification records that DASR 145 organisations are required to retain under EN4179 Para 8.2 to demonstrate they meet the EN4179 requirements to be certified as a Level 3.

If the applicant holds certifications in multiple methods, only evidence from one NDT method is required. The employer is to ensure that certification records for all other methods are retained, as required by EN4179 Para 8.2.

Note: that DASA may request evidence of ongoing EN4179 compliance for NDT RL3s in the course of oversight and enforcement activities.

8.3.2.30 DASA does not require the involvement of the Australian National Aerospace NDT Board (NANDTB) in the certification of Level 3 staff. DASA will not request or rely on NANDTB recognition when assessing NDT RL3 Form 4 applications.

8.3.2.31 For questions about NDT RL3 Form 4 application evidence please email: dasa.dca@defence.gov.au

8.3.2.32 Responsibility for appointment of NDT RL3 personnel is as follows:

ADF DASR 145 MOs: the Directorate of Aviation Engineering (DAVENG), as Defence’s Structural Integrity Centre of Expertise33, performs the Defence NDT RL3 function (refer to Section 4.2.3 for further details).

Non-ADF DASR 145 MOs (i.e. contractor organisations): are responsible for appointing their own NDT RL3 personnel.

8.3.2.33 Notwithstanding the fact that Level 3 personnel may be qualified via EN4179 to establish and authorise methods, techniques, etc., this does not permit such personnel to deviate from the methods and techniques published in the Instructions for Continuing Airworthiness (ICA)44 unless the ICA expressly permits such deviations (refer AMC 145.A.30(f)). Although it is recommended that Level 3 personnel have a role in NDT ICA deviations or changes (refer DASP Manual Volume 3 Section 7.2.5), NDT ICA deviations or changes must be approved in accordance with DASR 21.

Qualification of Personnel for Composite Repairs

8.3.2.35 SAE AIR4938 Revision C includes requirements for both initial training and on-going certification. Superseded revisions of SAE AIR4938 do not include the requirements for ongoing certification, and also omit the training curriculum for bolted composite repairs. Superseded revisions of SAE AIR4938 should not be used without approval from DASA.

supervision requirements

OEM or aircraft type specific training

8.3.2.37 Applications to DASA to officially recognise alternate qualification standards should demonstrate that the alternate standard:

provides an equivalent level of training to SAE AIR 4938; or

is suitable in the context of the specific MO and the scope of the maintenance activities to be performed. In such cases, the application should clearly state the scope of the activities being performed, how the training is suitable for that scope, and the means by which the scope is to be controlled.

8.3.2.39 DASR 145 MOs can utilise any training course that demonstrates compliance to the standard. Note that DASA-DAVENG, as Defence’s Structural Integrity Centre of Expertise, conducts the certification (initial and re-certification) for all ADF DASR 145 MO staff who perform composite repairs (refer to DASP Manual Volume 3 Section 4.2.3 for further details).

8.3.2.40 DASR 145 MOs are responsible for establishing training and authorisation systems to ensure that personnel who conduct composite repairs are appropriately qualified. Further guidance for ADF and non-ADF DASR 145 MOs is as follows:

ADF DASR 145 MOs: The MO should verify that technicians hold a valid PMKeyS proficiency (refer DASP Manual Volume 3 Section 4.2.3) for composite repair prior to authorising them to conduct composite repairs within an ADF DASR 145 MO. MO authorisations should only remain valid for the validity period of the applicable PMKeyS proficiency.

Non-ADF DASR 145 MOs: The MO should document their certification/re-certification process in their MOE. The standard does not impose specific requirements on who can conduct certification.

Qualification of Personnel for Aircraft Welding

8.3.2.41 The following paragraphs are applicable to DASR 145 MOs that perform aircraft welding repairs.

8.3.2.42 Welding is used in the repair of critical and non-critical airframe and engine components within Defence. As a specialist task, personnel conducting welding operations must be appropriately qualified in accordance with officially recognised standards.

8.3.2.43 CASA Civil Aviation Advisory Publication (CAAP) 33-1 (1) Aircraft manual welding: Approvals and qualifications provides information on how to apply for the initial issue or renewal of an aircraft welding authority under Civil Aviation Regulations. DASA has determined that a CASA welding authority, granted in accordance with CAAP 33-1 (1), is an appropriate qualification for Defence purposes.

8.3.2.44 DASR Requirement. DASR 145 MO that perform aircraft welding repairs must comply with DASR 145.A.30(f), which requires “Personnel who carry out any other specialised task shall be appropriately qualified in accordance with officially recognised Standards.”

8.3.2.45 Acceptable Means of Compliance. DASA considers a CASA welding authority, granted in accordance with CAAP 33-1 (1), is an appropriate qualification in accordance with DASR 145.A.30(f).

8.3.2.46 Organisations choosing to utilise welders qualified in accordance with CAAP 33-1 (1) must:

Ensure technicians hold a valid Civil Aviation Safety Authority (CASA) issued aircraft welding authority prior to task authorisation.

Ensure technicians are only authorised to carry out those types of welding processes that are specified in the welding authority document.

Ensure MO authorisations only remain valid for the validity period of the CASA-issued welding authority (i.e. renewal is required every 2 years IAW CAAP 33-1 (1)).

Aircraft Welding Questions and Answers

8.3.2.47 Q: What does a DASR 145 MO need so that it can use welders with a CASA welding authority?

8.3.2.48 A: The DASR 145 is required to:

Identify the scope of welding repairs that it requires (that is included in its overall maintenance scope).

Update the DASR 145 MO Orders, Instructions and Publications (i.e. MOE and any other associated documentation), to show compliance to DASR 145.A.30(f) and implement the required management framework. The aircraft welding repair training and qualification requirements should be specified in the MOE.

Authorise technicians who have obtained CASA welding authority

Ensure that authorised staff maintain their competency and CASA welding authority currency.

8.3.2.49 Q: How does a person achieve CASA welding authority?

8.3.2.50 A: CAAP 33-1 (1) details the framework that CASA applies to provide a welding authority, which is granted to applicants that have:

Successfully completed a relevant Australian Quality Training Framework recognised course; and

Passed the welding testing set out in the CASA Welding Syllabus.

8.3.2.51 Additional training may be required dependent on the specific work scope required by the DASR 145 MO. CASA will confirm any specific training requirements during the application for the welding authority.

8.3.2.52 DASR 145 MOs are responsible for organising CAAP 33-1(1) compliant renewal assessments for their personnel when required. There are a number of commercial organisations who employ CASA-authorised aircraft welding assessors (queries should be addressed to Contact us | Civil Aviation Safety Authority

8.3.2.53 CASA charge a fee to apply for the initial issue and for renewal of a welding authority. Applicants will also require a CASA Aviation Reference Number (ARN) prior to applying for a welding authority.

8.3.2.54 Q: Do welders require renewal of their CASA welding authority?

8.3.2.55 A: Yes. CAAP 33-1(1) requires a two yearly renewal in order to remain current. DASR 145.A.30(f) requirement that “Personnel who carry out any other specialised task shall be appropriately qualified in accordance with officially recognised Standards” requires a current CASA authorisation.

8.3.2.56 Q. Who covers the cost of gaining a CASA welding authority and renewal?

8.3.2.57 A: For:

Defence Maintenance Organisations, initial authority for ASTTECHs is covered within the Welder Aircraft Course at RAAFSTT, all subsequent renewal costs are to be supported though unit, or parent command funding.

Contractor Maintenance Organisations, refer to arrangements detailed in your contract.

8.3.2.58 Q: Can a non-welder supervise the conduct of a renewal welding assessment?

8.3.2.59 A: No. CASA requires that a CASA-authorised assessor supervise the conduct of welding examinations, and DASA has adopted this position.

8.3.2.60 Q: Can an organisation authorise welders with a different qualifications (in lieu a CASA welding authority)?

8.3.2.61 A: Yes. DASR 145 MOs who wish to use an alternative qualification to that stipulated in AMC1 145.A.30(f) should seek approval from DASA (as AltMoC).

8.3.2.62 For further information refer to the following:

For issues relating to the use of CASA welding authority within the DASR context please contact the DASA Desk Officer assigned to your organisation or email dasa.dca@defence.gov.au.

For queries related to gaining and maintaining CASA welding authority and the application of CAAP 33-1 (1), refer Contact us | Civil Aviation Safety Authority

Introduction

8.3.3.1 This chapter provides guidance in relation to the Certificate of Release to Service (CRS) process for aircraft maintenance. The document aims to consolidate the applicable requirements from different sections of the DASR and describes the intended outcomes in relation to Sign-off & subsequent CRS at the completion of maintenance.

Background

8.3.3.2 Maintenance carried out on an aircraft, its systems and its components must be certified at completion and prior to its return to service. The instrument used to achieve this outcome is the CRS which must be issued before flight at the completion of maintenance. The CRS should contain as a minimum (AMC 145.A.50(b)):

Basic details of the maintenance that was carried out;

Date such maintenance was completed;

Identity of the organisation and person issuing the CRS; and

Limitations to airworthiness or operations, if there are any.

8.3.3.3 The requirements for CRS reside across multiple regulation subsections (DASR M and DASR 145) that collaboratively inform the regulated community of DASA's requirement. This chapter summarises the applicable requirements for CRS to assist the community in meeting the DASR.

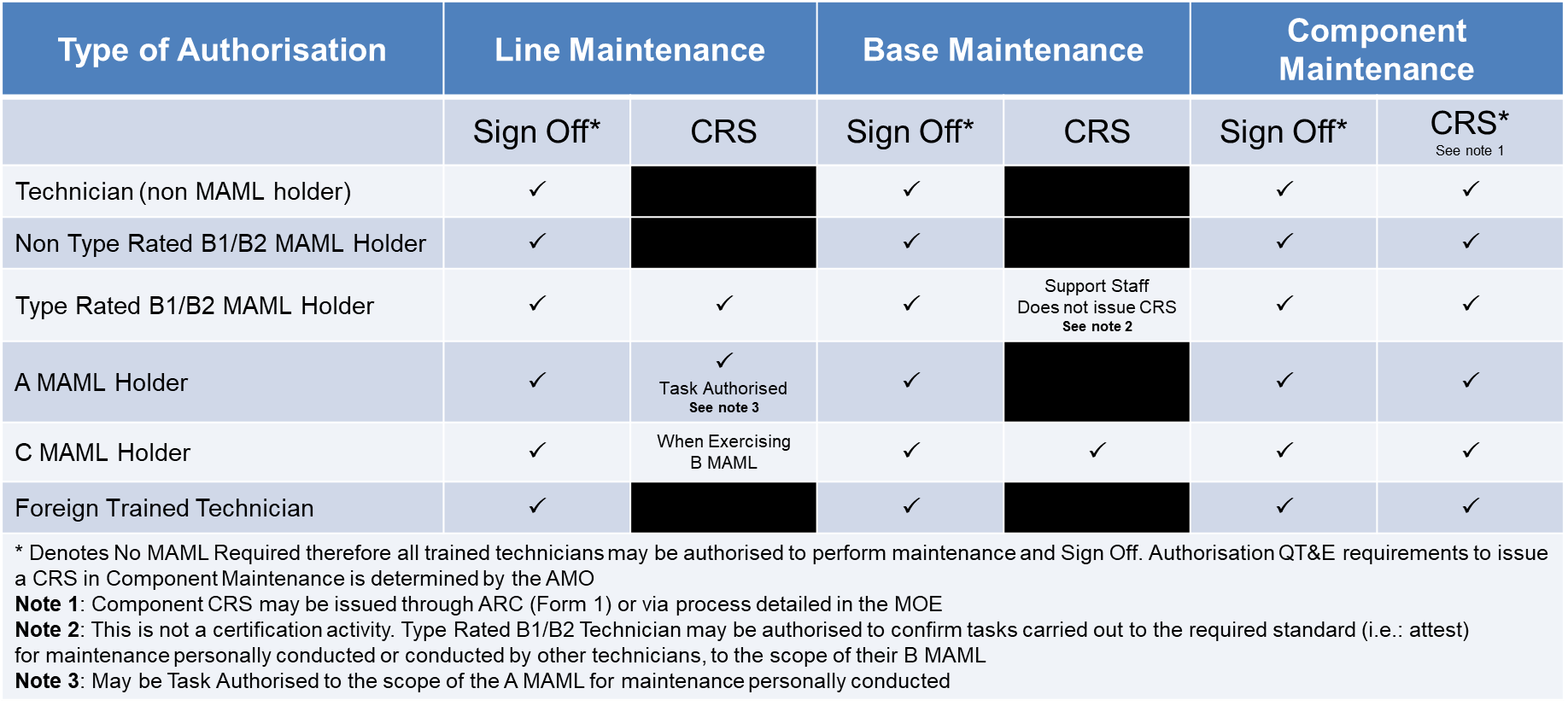

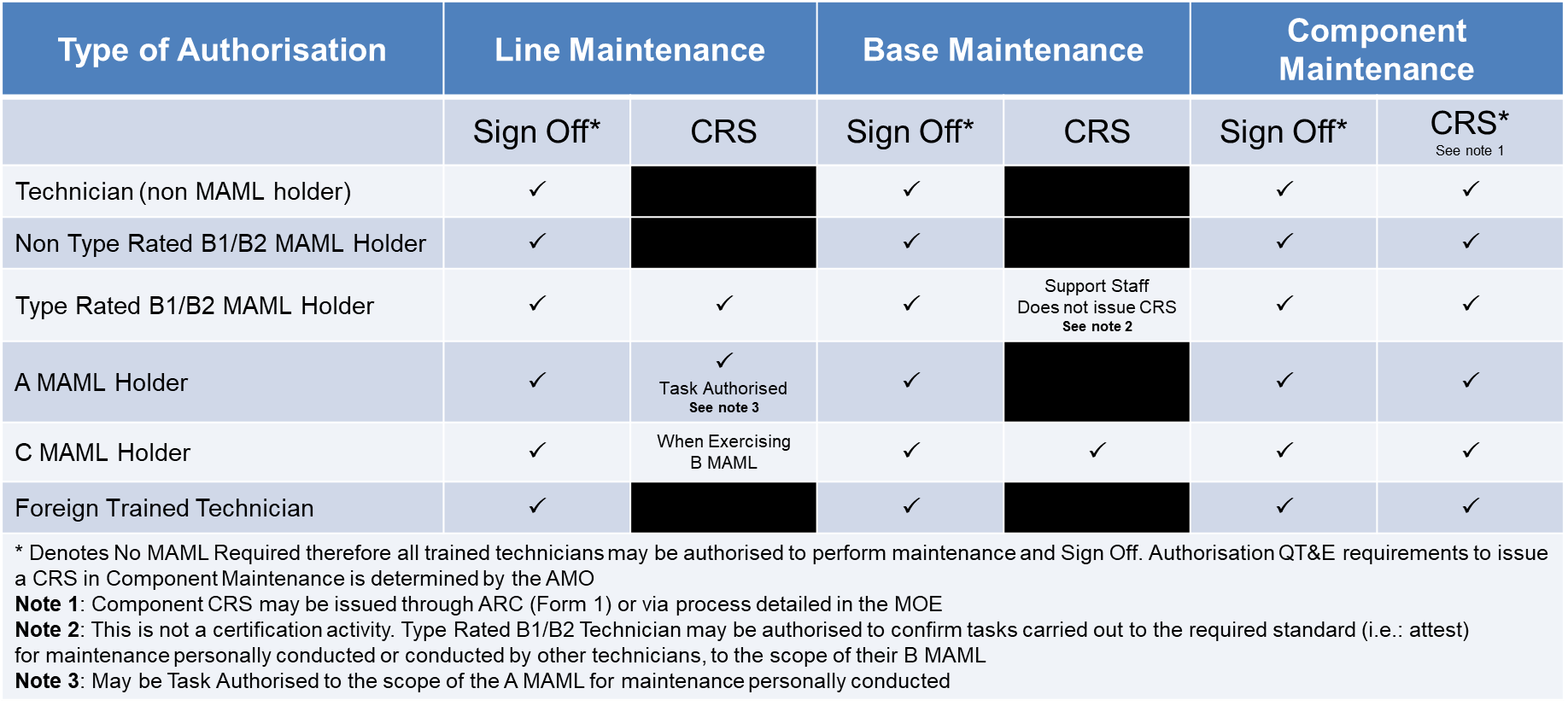

Certification of Maintenance Responsibilities

Continuing Airworthiness Management Organisation responsibilities

8.3.3.4 CAMO responsibilities are described in detail within DASR M and include:

the CAMO is responsible for all activities aimed to determine the airworthiness status of the aircraft and to appropriately plan and coordinate maintenance.

ensuring that all maintenance requirements (Airworthiness Directives (AD), Aircraft Maintenance Program (AMP) requirements, defect rectification, etc...) are complied with and released by a DASR 145 Maintenance Organisation (DASR 145 MO) (or equivalent (M.A 708(b)).

the CAMO is responsible for planning and ordering all required maintenance and for ensuring that all ordered maintenance conducted by the DASR 145 MO or equivalent is complete and has a CRS. The CAME must explain how this is achieved.

DASR 145 Maintenance Organisation responsibilities

8.3.3.5 The DASR 145 MO (or equivalent) responsibilities are described in detail in DASR 145 and include:

the development of ‘certification of maintenance’ procedures that ensures all maintenance actions have been properly coordinated and the CRS is issued within a reasonable timeframe after the actual performance of the tasks;

issuing a CRS following maintenance; and

the CRS issued has to be recorded in the Continuing Airworthiness (CA) record system. This information shall be available to the aircraft captain (refer to DASR M.A.306 and AMC DASR M.A.306(a), who is ultimately responsible for accepting the aircraft before a flight takes place.

DASR 145 maintenance personnel responsibilities

8.3.3.6 The completion of maintenance requires two actions. They are:

a ‘sign-off’; and

a CRS.

8.3.3.7 These two actions may be performed by a singular person or group of people dependent upon maintenance complexity, qualifications and authorisations.

Maintenance Authorisation

8.3.3.8 A person can only be authorised when they have met all the organisation’s applicable qualification requirements, and only for the scope of work applicable to that qualification detailed in the DASR 145 Maintenance Organisation Exposition (MOE). A person can carry out maintenance and sign-off tasks that they have performed for a particular maintenance activity, and also be a support or certifying staff for another. As an example, a person may be authorised to sign-off on an aircraft type, and certifying and/or support staff on a different aircraft type.

8.3.3.9 DASR 145.A.35 (i) requires the maintenance organisation to nominate an individual66 responsible on behalf of the maintenance organisation for issuing certification authorisations to certifying staff.

Sign-off Authorisation.

8.3.3.10 This is exercised by a competent (IAW AMC1 145.A.30(e)) and appropriately authorised person, that the maintenance has been completed to the standard required in accordance maintenance data specified in DASR 145.A.45.

8.3.3.11 AMC 145.A.65(b)(3)3 states that, in order to prevent omissions, every task or group of tasks should be signed-off by authorised personnel after its completion. It also states that a sign-off relates to one step in the maintenance process and is different from a ‘release to service’ (CRS). Importantly, a sign-off is a statement by the competent person performing or supervising the work, that the task or group of tasks has been correctly performed.

8.3.3.12 Furthermore, this AMC states that work by ‘unauthorised personnel’ (temporary staff, trainee/apprentice) must be witnessed by the authorised person before they sign-off. This means the authorised person signing off the task is responsible for the task.

8.3.3.13 IAW AMC1 145.A.30(e) personnel performing the sign-off, “shall be able to carry out tasks to any standard specified in the maintenance data, and will notify supervisors of mistakes requiring rectification to re-establish required maintenance standards”.

8.3.3.14 Nevertheless, holding a sign off authorisation doesn’t mean that the authorised person can sign off all tasks. It means that they can sign off tasks within the scope of their authorisation, depending on the qualifications, training and experience held, and in accordance with a procedure described in the MOE. Sign-off authorisation does not need to be restricted to singular tasks where the technician is required to/has demonstrated a degree of competence for that task. In contrast, the technician shall demonstrate competence in performing or supervising work applicable to their training and qualifications.

8.3.3.15 Further details related to task completion and sign-off can be found in Chapter 8.3.2 – Performance of Maintenance.

Certificate of Release to Service

8.3.3.16 In executing the obligations of DASR 145.A.50(a) the organisation must have procedures in place that ensure:

the individual issuing the CRS is appropriately authorised to do so;

the individual issuing the CRS has ensured the maintenance has been carried out correctly using appropriate procedures IAW DASR 145.A.45(b); and

as a result of the maintenance conducted there are no defects which are known to ‘endanger flight safety’.

8.3.3.17 A CRS is an attestation made by Certifying Staff by way of a certification signature after the completion of maintenance within their authorisation scope. The certification signature creates a ‘certificate’ and thus accountability, signifying that the maintenance or group of maintenance activities can be released to service. In Line maintenance the holder of a category A, B1 or B2 MAML may issue a CRS within the scope of their MAML and authorisation. In Base Maintenance the holder of a category C MAML is required to issue the CRS after the completion maintenance within the scope of their MAML and authorisation. Issue of a CRS in Component Maintenance can be done by appropriately authorised certifying staff, in this instance the individual does not need to hold a MAML.

8.3.3.18 There are two elements that need to be fulfilled by the authorised Certifying Staff before the issuance of a CRS is possible:

Ensure. Verify through oversight and management to ensure that the maintenance has been properly carried out; and

Assessment. Ensuring that no non-compliances which are known to exist that could ‘endanger flight safety’

How do Certifying Staff “ensure that the maintenance ordered/tasked has been properly carried out”?

8.3.3.19 Verification through the supervision of the maintenance task. Certifying Staff ensure that maintenance has been properly carried out by ensuring maintenance has been conducted in accordance with procedures detailed in the MOE and through the correct use of maintenance data as specified in DASR 145.A.45.

8.3.3.20 This statement does not necessarily mean that authorised Certifying Staff have to personally perform or supervise77 the whole process of every task, rather it is expected that Certifying Staff will (non-exhaustive list):

make sure that personnel assigned to perform the maintenance are authorised to sign-off the work for the appropriate scope of their authorisation;

coordinate the different tasks associated with the maintenance being performed; and

be available to support personnel in case of any mistakes or unexpected difficulties.

8.3.3.21 Authorised Certifying Staff are responsible to determine the amount of involvement they require in order to be satisfied that the maintenance can be issued a CRS. Subsequently, the DASR 145 MO cannot limit Certifying Staff in terms of what level of supervision they put in place for the maintenance task. The DASR 145 MO may however set a minimum requirement.

How do Certifying Staff, “make an assessment that there are no non-compliances which are known to endanger flight safety”?

8.3.3.22 This is achieved by a cognitive process that assesses whether an endangerment to flight safety exists as defined within AMC1 DASR 145.A.50(a) against the physical outcomes of maintenance ordered by the CAMO. It does not require the DASR 145 MO to find or become responsible for hidden defects which are not expected to be discovered during the ordered maintenance. Defect assessments, including those endangering flight safety, must be clearly identified in the CA records system along with any corresponding limitations (if any) for further CAMO consideration.

Considerations for when the aircraft is left in a non-airworthy condition

8.3.3.23 In circumstances where after performing the maintenance ordered by the CAMO, the aircraft is left in a non-airworthy configuration, a CRS can still be issued for the maintenance that has been completed. The CRS can be issued as long as the incomplete maintenance or known defects are properly identified in the CA records system and communicated to the CAMO. For example, where the DASR 145 MO removes an engine for preservation (without installing a new one), or where the organisation performs an NDT inspection and identifies a crack outside limits.

8.3.3.24 The circumstances mentioned above (including defects affecting flight safety discovered during maintenance), can be properly addressed by using the provisions contained in DASR 145.A.50(c) and (e).

8.3.3.25 It is important to appreciate that a CRS does not mean that the aircraft is airworthy and ready for flight. A CRS is issued by the DASA 145 MO for the maintenance performed; the CAMO is accountable for ensuring that all CA requirements are met for the aircraft to undertake its assigned mission before releasing to the Operator.

When is a CRS issued?

8.3.3.26 IAW DASR 145.A.50(b) “A certificate of release to service shall be issued before flight at the completion of any maintenance”. Subsequently, “any maintenance” can be interpreted in multiple ways, such as:

any maintenance task.

any combination of maintenance tasks.

any maintenance event.

8.3.3.27 Utilising the flexibility afforded by the “any maintenance” interpretation an organisation may choose one or more of the following systems of release to service:

Several CRS are issued, each one of them covering a different single maintenance task.

Several CRS are issued, each one of them covering a different group of maintenance tasks.

A single CRS is issued covering all the maintenance included in a maintenance event.

8.3.3.28 The organisation must ensure that the CRS issued to the CAMO clearly identifies what maintenance is complete. If there is any incomplete maintenance, the CRS must clearly identify it in the CA records system and the corresponding limitations (if any). In each of the above cases, it is important to note that there is no change in the accountabilities of the individual authorised Certifying Staff in signing the CRS.

Who can issue a CRS in Line Maintenance?

8.3.3.29 Only appropriately authorised category A, B1 and/or B2 MAML holders can issue a CRS in Line Maintenance. The scope and responsibility of each license category is provided below.

Limited Certification Authorisation

8.3.3.30 By way of exception to paragraph 8.3.3.29, and in accordance with 145.A.30(j) 4, in unforeseen cases where the aircraft is grounded or operating away from a Main Operating Base, and where no appropriate certifying staff are available, the maintenance organisation may issue a limited certification authorisation to the aircraft commander on the basis of the flight crew licence subject to being satisfied the aircraft commander can accomplish the specified task to the required standard. These provisions shall be detailed in a MOE procedure.

One off Certification Authorisation

8.3.3.31 In unforeseen cases, where an aircraft is grounded at a location other than the main base where no appropriate certifying staff are available, the maintenance organisation may issue a one-off certification authorisation in accordance with 145.A.30(j)5.

Category A licence

8.3.3.32 The category A licence permits the authorised MAML holder, in a Line Maintenance environment only, to issue CRS for work that the licence holder has personally performed (‘sign off’) and within the scope of their certification authorisation.

8.3.3.33 A category A licence does not permit the authorised MAML holder to issue a CRS for the work of others, only for their own maintenance. While other personnel may be present and directed by the authorised A MAML holder in providing assistance during the performance of the maintenance task, the category A MAML holder may not undertake a supervisory role.

Category B licence

8.3.3.34 The category B1/B2 licence permits the authorised MAML holder to issue CRS, within the scope of their license and certification authorisation on maintenance that has been ‘signed off’ by themselves or other authorised personnel, within the scope of their license and certification authorisation.

Category C licence

8.3.3.35 The category C licence permits the authorised MAML holder to issue a CRS following Base Maintenance on aircraft carried out by a DASR 145 AMO. By definition, the DASR permits an authorised category C MAML holder to issue a single CRS for all maintenance activities pertaining to the aircraft during a single Base Maintenance visit.